Tmt Bar Bending Machine

65,000 - 1,250,000 Per

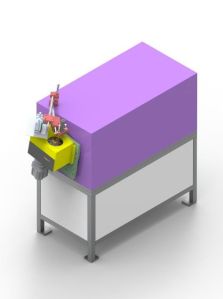

BAR BENDING MACHINE Model: SEC-GW-42J Type – Mechanical Bending Rebar Diameter: 6-40 mm Plate Diameter:360 mm Bending Speed: 3-15 r/min Motor Power: 4 KW Motor Speed:1440 rpm Voltage: 415V Total Weight: 380Kg

CNC Multipurpose Hydraulic Busbar Processing Machine

975,000 - 1,555,000 Per Piece

1 Piece (MOQ)

Best Deals from Bending Machine

Rebar Bending Machine

125,000 - 250,000 Per Bag

1 Bag (MOQ)

Rebar bending machines are essential tools in construction projects where the rebars need to be shaped according to the structural design. These machines offer several advantages, including increased efficiency, accuracy, and consistency in bending rebars, which leads to better quality construction and reduced labor costs.

Wire Bending Machine

Get Price Quote

Wire Bending Machine. Manufactured by making utilization of value affirmed segments and creative innovation under the direction of our gifted experts, this machine is very treasured among our client for its high usefulness and long administration life. Our offered machine is broadly requested in automobile, electrical and general engineering industry. Further, we give this Wire Bending Machine in different models and specialized determinations at absolute bottom costs.

AI GW40J TMT Bar Bending Machine

95,000 Per Piece

1 Piece (MOQ)

Tmt Bar Bending Machine

Get Price Quote

1 piece (MOQ)

fully automatic pvc pipe bending Machine

200,000 Per piece

1 piece (MOQ)

Mechanical Plate Bending Machine

115,000 Per Piece

1 Piece (MOQ)

Automatic UPVC Pipe Bending Machine

Get Price Quote

1 piece (MOQ)

Rebar Bending Machine

71,000 - 125,000 Per Piece

1 Piece(s) (MOQ)

Rod Bending Machine

Get Price Quote

1 Piece (MOQ)

GW-50 Bar Bending Machine

105,000 Per Piece

1 piece (MOQ)

Fitted with manual forward/reverse switches, automode switch, two angle setting switch, auto/manual selection switch, foot pedel, quick setting pin for instant bendling angle setting, adjustable die arm for fine setting, oil indicator

Bar Bending Machine

Get Price Quote

Special Pipe Bending Machine

Get Price Quote

Supported by superior transportation system, we can easily make safe and quick deliveries within the promised time span. We are backed by a well-structured and capacious storage unit wherein we store the entire lot in a secured manner. Moreover, we ensure complete security of the stored items. Details : The SSEGPL's pipe bending machine (PBM) is designed for Bending the steel pipe of various thickness and diameters with the high quality results. Fully equipped control panel with automatic emergency shut off that allows total control to the operator. Pin-up clamp automatically grips the pipe to prevent distortion. Operator can easily convert to another pipe size within the machine range is made by fitting an alternative bending set. SSEGPL's Pipe Bending Machine is capable to bend all grades of API-5L pipes withing its range. Stiff back rod allows the operator to do consistently uniform bending of pipes. Hydraulic driven winch for pipe movement. Each pipe bending machine requires a Bending Die Sets, a Mandrel and a Bending Belt (Steel Lined Choker Belt). Mounted with rubber tiers of steel tracks with a towing tongue. Available for pipe Sizes 6” To 60”.

Bar Bending Machine

Get Price Quote

1 Piece (MOQ)

Features : Flush type panel helps for free movement of operator. Safety lock on pin ensures the roller does not come out while machine is in operation. Stand for bar guiding and length measurement. Moveable saddle and rollers for quick Operation. Pre-set bend angle selection through control panel.

Steel Bar Bending Machine

Get Price Quote

1 Piece (MOQ)

U Bolt Bending Machine

Get Price Quote

1 Piece (MOQ)

A U bolt bending machine is a specialized piece of equipment designed for forming U-shaped bolts from metal rods, commonly used in a variety of applications such as fastening pipes, securing objects to walls, or mounting machinery. U bolts are widely used in industries like construction, automotive, marine, and transportation, making the precision and consistency of these machines essential for high-quality production. Key Components: Bending Dies: These are designed to form the “U” shape by bending the metal rod around a specific radius. The dies are often interchangeable to allow for different bolt sizes. Clamping Mechanism: Holds the rod securely in place while the bending process is carried out. Bending Arm or Rollers: These components push or roll the metal rod into the shape of a “U.” Some machines use a rotary arm to bend the rod, while others use rollers. Control System: An interface that allows the operator to set bending angles, radius, rod length, and other parameters to ensure consistent production. Cutting Mechanism: Many machines come with a cutting system that trims the rods to the desired length either before or after the bending process. Feeding System: Automatically feeds the metal rod into the machine. In automated systems, the rods can be fed continuously for mass production. Working Principle: The straight metal rod is fed into the machine, where it is clamped securely. The bending dies or arms are positioned according to the desired U bolt dimensions. The machine bends the rod around the dies to form the U shape, either by pushing, pulling, or rolling the rod. Once the U shape is formed, the machine may cut the rod to the required length, depending on the machine’s configuration. Types of U Bolt Bending Machines: Manual U Bolt Bending Machine: A basic version where the operator manually bends the rod, typically for small production volumes or custom-sized U bolts. Semi-Automatic U Bolt Bending Machine: Involves some manual input but mechanizes the bending process, making it faster and more consistent than fully manual machines. Fully Automatic U Bolt Bending Machine: Designed for high-volume production, these machines automatically feed, bend, and cut the rods with minimal operator intervention. CNC U Bolt Bending Machine: A computer-controlled machine that offers high precision and can be programmed to produce U bolts of different sizes and shapes in large quantities. Ideal for industrial-scale production. Applications: Construction: U bolts are used to anchor pipelines, secure structures, and fasten heavy equipment to concrete or other materials. Automotive: Used for attaching parts like exhaust systems, leaf springs, and chassis components. Marine: Securing boat engines, equipment, and rigging. Electrical: Fastening conduit or cable management systems. Transportation: Securing loads on trailers or mounting components on heavy-duty vehicles.

Bar Bending Machine

110,000 Per Set

1 Set (MOQ)

Hydraulic Pipe Bending Machine

22,500 Per Piece

1 Piece (MOQ)

‘JMTC’ Hydraulic Pipe Bending Machine is very useful machine for heavy section pipes with ease of hand strokes. These are best suited for C –class pipes used for gas, water, steam lines of fabrication work. Hydraulic Pipe Bending Machine is provided with bending forms for bending. The cylinder is fitted with Low pressure and High pressure Double Plunger pump. Machines upto 3” capacity are provided with a tripod stand whereas higher capacity machines are supported with castor wheels. This is available in manual as well as power operated models. Steel cast bending dies are also available upon request

stirrup bar bending machine

32,000 Per Piece

1 Piece (MOQ)

Bar Bending Machines

110,000 Per piece

1 piece (MOQ)

Bar bending machine Max 36 mm Three phase

GW 42 Bar Bending Machine

85,000 Per Piece

1 Piece (MOQ)

We “Mehak Metals” Wholesale Trader, Distributor, Manufacturer and Retailer of an extensive array of Light Construction Machine, Accessories For Light Construction Machinery

GW52J Bar Bending Machine

75,000 Per Unit

1 Unit (MOQ)

UNI 20 Stirrup Bending Machine

30,000 - 40,000 Per Piece

1 PCS (MOQ)

Stirrup bending machine has another name called ring making machine. This machine is with a wide range of being used In building and ccostniction indushies. Stirrup making machine to some extent Is one kind of bar bending machine, but ithas some functions thatthe normal bonding machine does not have. Stirrup bender can bend bar, rebar, reinforcing bar and steel within 180 into different forms according to different settings, for example. Mangle. quadrangle, pentagram, polygon and ring. Besides, this machine can also bend metals into 1.1. shape. Thais why stirrup bending machines are also called U-bending tools. Unicom automatic Stirrup Bending Machine is Most Durable, Rugged, Stable Bending Machineto bend die from4m.m to 20m.m.Bar Bending machine (GF-20)is speciallydesigned for heavy Duty rebar and high on demand for construction job site application. Such as simple bending process, high woreelliciency, convenient angle for adjustment and neat bending results.The function of stirrup bending machine is to bend bars into trade*s of shapes according to different requirements, such as rectangle, square and other simple shapes. Unicorn automatic stirrup bending machine can bend round steel bar with diameters from 4mm to 20mm. Both the processing scope and We external adjuster are optional, mitres type of machine is quite convenient to use. UNI 20 &UNI 20D are similar to each other Their structure is relatively simple and their work capacity is relatively lower compared with the other two sines of stirrup machines. Buttheyare very flexible to operate. These bar machines have a button that can swftch bending angles from 90r to 135. directly, because base two arcs are more often being used. Besides, our Unicorn Whop machines are able to bend bars into any other angles with 180.. Because GW20 & GF20 are semioutomatic, they can be easily operated by hand to decide what arcs you want to make. GF20 is the machine with a numerical control panel from a wide range of round bar with diameters between 4mm and 20mm. You can seta certain angle within 180 on the control panel. It is easy and reliable to operate. This automatic stinup bender can save labor and improve efficiency of processing bars. Application : GW20 & GF20 Steel bar bending machine can be used efficiently to bend ordinary carbon steel, hot-rolled steel, screw bar, flat bar, square bar and angle Waal bar which am widely used in machining and construction project. Specifications : Compact structure Stable performance Coppery males Flexible and easy to operate Good steel work disk High working efficiency Strong Durability Easy to maintain Product features : Adopts the 10mm thicken top plate and high rigidity disk of iron, more durable. Equipped with international standard copper motor, ultra-high hardness accessory and adjustable fender. Adopt 6mm thick top plate, high rigidity disk, adjustable stylobate, the bending angle of more efficient. Equipped with international standard copper wire brake motor, narrowing inertance when the machine stops and bending angle is more accurate.

Rebar Bending Machine

130,000 Per piece

1 piece (MOQ)

Hydraulic Press Brake Bending Machine

500,000 Per piece

1 Set(s) (MOQ)

We are offering hydraulic press brake bending machine.

Letter Bending Machine

Get Price Quote

Pipe Bending Machines

300,000 - 700,000 Per piece

We are offering pipe bending machines. Pipe bending machine to bend the pipe to certain angle. To produce bend in l shape, u shape etc. Available in mechanical model, hydraulic model. Operation can be manual and semi automatic.

Hydraulic Small Pipe Bending Machine

Get Price Quote

1 Piece(s) (MOQ)

When it comes to design and manufacture bikes and two-wheelers accessories, you need to bend the metal accordingly and for this, Accessories Pipe Bending Machine is important. It’ll not only speed up your work but doubles your productivity in the least time as well. Bend-Tech India – one of the leading Accessories Pipe Bending Machine Manufacturers in Delhi/NCR has the machine available in different models for ensuring trouble-free working.Reasons Why You Should Invest In Accessories Pipe Bending Machines: Ease The Bending Work: With Accessories Bending Machine, you’ll be able to obtain wrinkle-free bends. Using it indeed has many advantages and ease of bending is just one out of all. Ease The Operator Work: The working of Accessories Pipe Bending Machine is easy and quick and one doesn’t need any special training for getting benefits out of the same. Low Maintenance: The machine is made of quality components and advanced technology, which ensures its trouble-free working without any need for maintenance over and over again.

Bar Bending, Cutting Machine

Get Price Quote

We offer our clients, automatic bar bending cutting machine, which is widely appreciated for its smooth functioning and high productivity. The bar bending cutting machine manufactured by us is acclaimed for its efficient working on the building sites. In addition, our bar bending cutting machine is completely safe to use and highly effective. salient features : capable of performing many operations such as cutting, bending, making stirrups, spiralsgears on bearingscontinuous lubrication in bending and main friction pointsparts of the machine are made of hard alloy steelassured safety in its operationsimultaneous working of the bending disc and the shear arm, by pedalin spite of removing the pins of the bending disc, the sheers constantly runsemergency stop buttonsin case of misuse automatic emergency returnseasy handing and high yield different weight available : 400 kg450 kg500 kg » specificationsmodel combinationstensile strengthcutting (no. Of bars)bending (no. Of bars)rpmmotorapp. Weightapp. Dimension (in cm)12312rbc-26/3245 kg/sq. Mm23201632202113 h.p.400 kg88 x 105 x 9085 kg/sq. Mm201411262816rbc-32/3645 kg/sq. Mm322520362824105 h.p.450 kg90 x 105 x 9085 kg/sq. Mm251814282216rbc-38/4545 kg/sq. Mm382522453025105 h.p./ 7.5 h.p.500 kg90 x 100 x 9285 kg/sq. Mm322218362520