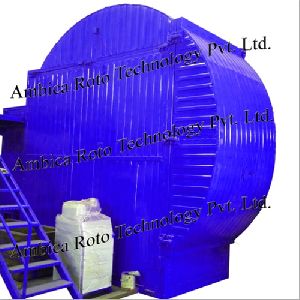

4-Arm Bi axial rotomoulding machine

Get Price Quote

We are leading manufacturer and exporter of 3-arm and 4-arm bi-axial rotomoulding machine to our premium clients across the india and overseas.this machine is developed after extensive research and study of industry norms and as well as client requirement and the technical specifications detailed by them.

Single Arm BI Axial Machine

Get Price Quote

1 Piece(s) (MOQ)

Features : Low capital Investment best for startup project. Minimum overheads charges due to less space & Automatic operation Low cost machine to produce best quality 2/3/4 layer tanks with minimum weights. Excellent quality multilayer tanks possible. Any type of rotomolded products can be produced at low investment Faster ROI. Due to low investment, low running cost, less space, Unskilled operator can run machine. Less rejection rate. Low power, low fuel consumption cost Most suitable machine to produce even Bigger size tanks. Application : For large size tanks like 3000 to 40,000 Ltrs / 10,000 USG and large size simple and cylindrical rotor articles. Start Up project due to low cost.

Best Deals from Bi Axial Machine

biaxial rotomoulding machine

Get Price Quote

Three arm bi-axial rotational moulding machine model vi-3-1000x2. Highly suitable for large production needs.

biaxial rotomoulding machine

Get Price Quote

bi axial rotomoulding machine

Get Price Quote

Specially designed for the space saving chambers with efficient heat transfer technology.Insulation material for better working environment.Straight arm with two spacious spiders (optional) to accommodate different size moulds for convenient working.Provision for secondthird charging manhole on the top of oven for charging polymer without opening the oven doors. Oven controls are equipped with necessary interlocking and safety devices with alarm Micro processor based machine control panel with digital display (plc on request) Naroto offer bi axial three four arm an ideal machine for high volume production, even complicated sizes with similar working cycles. Moulders will appreciate its wide swing diameter from 60 to 240 inches. Sturdy steel structure with high efficiency out put and less maintenance are its principal features.

Rotational Moulding Biaxial Machine

50,000 Per Set

1 Set(s) (MOQ)

We are offering rotational moulding biaxial machine. 4 arm biaxial machine for high production of tanks capacity of 8 nos x 500 ltrs in one arm.

2 Arm Bi-Axial Rotomoulding Machine

1,600,000 Per Piece

1 Piece(s) (MOQ)

Application:Biaxial type Rotomoulding machines are specially designed to hold Small to heavy moulds as well as multiple moulds with various capacities. Provision for such heavy mould carrier plates or spider with wide range of diameter for arms are provided with heavy pedestal support for sturdy comfortable operation.

bi axial rotomoulding machine

2,500,000 - 5,500,000 Per piece

1 piece (MOQ)

biaxial rotomoulding machine

Get Price Quote

Most Efficient in Fuel and Energy Consumption Compared to Other types of machines.. Very Consistant Product Quality due to Smooth Bi - Axial Rotational, Highest Production Due To Lowest Cycle Time. Uniform Heating of the Mould with Forced Air Circulation in Heating Chamber. Uniform Distribution of Material of Hence Possible to Produce Tank with Lesser Weight. Best Compatibility in Market due to Lowest Production Cost Per Tank. Lowest Rejection Rate due to Sound and Proven Technology.

bi axial rotomoulding machine

3,000,000 Per Set

1 Set(s) (MOQ)

bi axial rotomoulding machine

Get Price Quote

NAROTO Bi Axial Rotomoulding Machine is mainly used in application where the process time for each arm required equal time for heating, cooling, unloading & loading. Also available for different applications like three stations, where time for heating, cooling, and unloading loading (common) area are provided.

Bi Axial Machine

Get Price Quote

Load Capacities 1kN to 200kN static & quasi static Self reacting high stiffness load frames Free standing, no foundation required Frame stiffness up to 600kNmm Up to 150 mm stroke servo electric actuators Digital Encoder for stroke measurement & control with resolution of 0.01micron Stroke accuracy ± 0.5% of read out value Speed accuracy ± 0.1% of set speed Works out of 1Ǿ 230VAC or 3Ǿ 415VAC Next generation DSP based servo controller with 32 bit data acquisition

bi axial rotomoulding machine

Get Price Quote

We have gained recognition as an eminent enterprise, devotedly engaged in manufacturing a broad range of Bi Axial Rotomoulding Machine.Description:We have come with newest making Bi-axial Rotomoulding Machine and Auxiliary Machineries for Plastic Industries. The company brings the world class information of Bi-axial Rotomoulding Machine and Rotomoulders in India.The Process: Rotational molding process is different as compared to other plastic processes.In the complete process, first the mold is loaded with raw material in resin from. The loaded mold is then shifted in to hot air oven where it is oriented and rotated at suitable low speed. As the molten resin gets properly heated oriented, it adheres to the mold's inner surface until completely fused. Then the mold is moved to the air, water or the both to slowly reduce the temperature when the mold is still in bi-axially rotating mode. Finally, the mold is dismantled to get the finished roto-molded product and is then again reloaded for next cyclic process.Salient Features:Most efficient in fuel and energy consumption compared to other types of machinesVery consistent product quality due to smooth bi-axial rotational, highest production due to lowest cycle timeUniform heating of the mould with forced air circulation in heating chamberUniform distribution of material of hence possible to produce tank with lesser weightBest compatibility in market due to lowest production cost per tank.Lowest rejection rate due to sound and proven technologyClean and silent operation of machineFlexibility to produce double and triple layer tanksAC variable drive for all minor and major axes for minute and accurate speed controlControl panel is equipped with ac drives, digital indicators, temperature controllers, timers and advance automation circuit for entire process control and all necessary safety features.

3 arm bi axial rotational Moulding Machine

1,500,000 Per Piece

1 Piece(s) (MOQ)

Single Station Bi-Axial Machine EN-500x2

Get Price Quote

We are offering single station bi-axial rotational moulding machine one straight arm capacity two tanks of 500 liter maximum. Typical cycle time 60 min. ( 20 min heating, 20 min cooling, 20 min loading & unloading ) fully automatic italian burner, diesel or lpg or natural gas fuel consumption cycle 3.0 liter diesel or 2.5 kg of lpg electric load 3.5 h.p. Process temperature 210 oc production in 24 hrs 48 tanks of 500 lit. Size of machine l 3.6 mtr x w 3.5 mtr x h 3.5 mtr

Three Arm Bi Axial Machine

2,500,000 Per Piece

biaxial rotomoulding machine

Get Price Quote

We are Supplier and Manufacturer by Biaxial Machine Exporter, Biaxial Rotomoulding Machine, Bi-axial Machine ,Bi-axial Moving Oven Type Rotational Moulding Machine for NK Industries Ahmedabad, India. Biaxial Rotomoulding Machine NK Industries Provides Biaxial Rotomoulding Machine, Biaxial Rotomoulding Machine, Bi Axial Moving Type Machine, Rotomoulding, Supplier in India.

Bi Axial Rotational Molding Machine

Get Price Quote

Bi Axial Rotomolding Machine

1,400,000 - 2,600,000 Per Piece

bi axial rotomoulding machine

Get Price Quote

We are manufacturer of Rock & Roll type machine upto 20,000 liters capacity. We also provide in this machine gas or diesel fire system. This machine use for manufacturing of big size articles.

BI AXIAL MACHINE FOR WATER STORAGE TANK

Get Price Quote

Bi Axial Rotomoulding Machines Is Made By Neelam Roto Plast.Bi Axial Rotomoulding Machines is also manufactured by our organization under the supervision of our skilled professionals that allow us in manufacturing defect free range of products. These machines are helpful in serving various industrial applications. These products are widely accepted in the market for low maintenance, best quality and longer functional life. Feature: Longer functional life Minimum maintenance Optimum performance high Production low fuel consuption easy to oprate Other Details:

Bi-Axial Rotational Moulding Machine

Get Price Quote

> advanced designed machine. > fully automatic & compact for consistent quality product. > sturdy & unique mechanical design for trouble free running. > high efficient heating chamber for the best fuel economy. > all electricalmechanical safety interlock for safe working. > high efficient lpgdiesel burner for fuel economy. > specially design blowers to work under high temperature. > unique design for easy maintenance.

Single Station Bi-axial Machine

Get Price Quote

Complete Robust & Sturdy construction for long lasting performance. ✔ Single fix Arm and fix oven Machine. ✔ Standard Model is with AC drive and AC motor. ✔ Main shaft on heavy-duty spherical roller bearings. ✔ Inbuilt re-circulating blowers. ✔ Suitable for “Multi Layer” tanks. ✔ Overload clutch for motor safety. ✔ Standard Motors and standard heavy duty Gearboxes. ✔ Machine is specially design for Insulated foam tanks production. ✔ Auto-ignition package oil fired burner, Gas burner optional.

biaxial machine

Get Price Quote

Biaxial crusher, with small body, is easy to install and adapted for crushing small materials like plastic bottles, videotapes, CDs, raw garbage, etc. This type also provides easy maintenance.iaxial machine

Moving Oven Bi Axial Machine

Get Price Quote

we are offering Moving Oven Bi Axial Machine.

bi axial rotomoulding machine

Get Price Quote

Our Bi Axial machine is one of our featured products that exhibit engineering excellence in designing and manufacturing. Used widely in moulding of plastic items, this machine is designed not only to produce quality product but also enhance the rate of production. Featured with options of three and four arms made of high quality mild steel our Bi Axial Rotomoulding Machine is designed to have the following features which make it stand apart from others in the market.

Bi Axial Machine

Get Price Quote

bi axial rotomoulding machine

Get Price Quote

we are renowned for offering the premium bi-axial rotomoulding machine. our bi-axial rotomoulding machine is precision engineered to offer high efficiency. our bi-axial rotomoulding machine is used in the manufacturing of many items in different industries. we offer these bi-axial rotomoulding machine as per the international standards for quality. bi-axial machine control panel : a.c. variable speed drive for major and minor axis for all armsuser-friendly inexpensive drive system capability to monitor each operation while doling out with auto and semi auto programmable process control systemsafety and alarm strategy provided for burners provided required inter locking system for affecting arms, oven and doors remote control panel for controlling process parameter and monitor the method technical specifications : biaxial machine is fully prepared with the following outstanding featuresdesign of biaxial machine made-up from mild steel which is sturdy reliable designdesign of biaxial machine made-up from mild steel which is sturdy reliable designchoice of three arm and four arm optionschoice of carry type machineschoice of fix oven or portable ovenoptions of straight-arm, offset arm, four mould carrier armsreverse / forward machinery for correct positioning of stationsheating oven with stipulation of two side doorsstraight arm with two roomy spiders to put up different size moulds for expedient workingstraight arm with unique four-mould carrier base plats to utilize the maximum oven space in order to put up four moulds for inexpensive working with zero refusaloffset arm with enough balancing weights for large size moulds and contented functioning designinspection windows to observe the mould rotation and polymer melting situation without opening the oven doorsstipulation for extra second and third layer charging manholes on the top of oven panel without opening the oven doorenergy competent world-class environment welcoming italian burners for lpg/oil and duel fuelefficient hot air scheming blower fans for fast heating of the moulds, implementing state. of the art knowledge and achieving unique wadding design with new generation energy economy insulation material for better working situationsolid oven design and oven shape for finest oven volume and reasonable working with less fuel utilizationexclusive blower design for capable air movementelective cooling station with high efficient air conniving fan or with water mist and water cover process of machine : load the powder foam polymer resin (material) in the mould, which mounted on the armsthe mounted mould arm goes inside the oven and heat started and circulating by blower the polymer resin start meltingthe melted resin sticks in all side of mouldwhen process completed, arm move to the cooling area and cooling process startswhen process completed, arm move to the cooling area and cooling process startswhen mould becomes cool the melted polymer resin convert into solid foam and shrinkafter completion of process, open the mould and take out finished product control : machine operated by control panelthere is a.c. variable speed for major and minor axis of the armsprovided limits for the oven and door while forward/reverse and open/close respectivelyinter locking system available for moving arm, door and ovenautomatic on/off system available for the burner to maintain required temperature

Bi Axial Machine

Get Price Quote

Product Specification Moving Oven Type Rotational Moulding Machine: - Specially Designed for the Energy Saving Environmental Friendly Heating Chambers with Efficient Heat Transfer Technology. - State of the Art Technology in Designing the Insulation Panels for Better Working Environment. - Straight-arm with Four Mould Carrying Carrier Plates for Economical Working. - Machine Controls are Equipped with Necessary Interlocking, Safety Devices with Indicators and Alarm. - Microprocessor Based Machine Control Panel with Digital Display. - Plc On Specific Request. - Variable Speed A/c Motors are for Major and Minor Speed Controls. - Mould Indexing Facility. - Environment Friendly Burners Suitable for Lpg/ Cng/ Oil/ Duel Fuels.

biaxial rotomoulding machine

Get Price Quote

rotomoulding moulds, Shuttle Rotomoulding Machine, Pulverizers