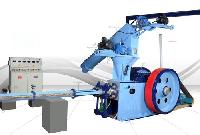

Biomass Briquetting Machine

Get Price Quote

1 Piece (MOQ)

Biomass Briquetting Plant

1,750,000 - 5,000,000 Per Set

* Application Biomass Briquetting Plant is for converting agro forestry waste (Bio-mass) to Briquettes (Bio-coal). * Description of Briquetting Plant ( Jumbo-90) The Briquetting Plant is a ram type press designed for continuous heavy-duty operation with two load wheels. One of the load wheels acts as a pulley, and driven by the main motor through a flat belt. Forced lubrication is provided by oil lubrication system which gives a longer life to the bushes. Dry agro - forestry waste as a raw material is fed through the screw conveyor to Kupy by means of vertical screws, with its own-geared motor. It pre-compress and forces the material downward into the feeder box. From the feeder box the material is forced by the Ram through Taper die and due to high pressure & heat, raw material (Biomass) is converted into solid cylindrical briquettes. Finally finished briquettes come out from die holder and passes through natural cooling lines. During Process lignin content in the raw material (Biomass) is transformed into liquid form & acts as a natural binder. Therefore it is called the Binder less Technology. Jumbo-90 is flagship model in Biomass briquetting industries. Jumbo-90 gives more production and minimum process cost per MT.

Best Deals from Biomass Briquetting Plant

Biomass Briquetting plant (Super- 60)

Get Price Quote

The Briquetting Plant is a ram type press designed for continuous heavy-duty operation with two load wheels. One of the load wheels acts as a pulley, and driven by the main motor through a flat belt. Forced lubrication is provided by oil lubrication system which gives a longer life to the bushes.Dry agro - forestry waste as a raw material is fed through the screw conveyor to Kupy by means of vertical screws, with its own-geared motor. It pre-compress and forces the material downward into the feeder box. From the feeder box the material is forced by the Ram through Taper die and due to high pressure & heat, raw material (Biomass) is converted into solid cylindrical briquettes. Finally finished briquettes come out from die holder and passes through natural cooling lines.During Process lignin content in the raw material (Biomass) is transformed into liquid form & acts as a natural binder. Therefore it is called the Binder less Technology. Super-60 Model is ideal for low production and best for waste management in agro and wood industries. If raw material ( Biomass) is available in powdery form, so this smaller model is suitable to convert Briquettes. Application : Biomass Briquetting Plant is for converting agro forestry waste (Bio-mass) to Briquettes (Bio-coal). Production Capacity of Biomass Briquetting plant ( Super- 60) : Output Production Capacity - 600 Kg/Hr Raw material ( Biomass) Specifications : Size of Raw Material - Up to 5mm Moisture contain - Max. 10 %. Output Briquettes (Bio-coal) Specification : Briquettes Diameter / Shape - 60 mm ( Cylindrical Shape) Briquettes Length - Not fixed ( around 1 Feet) Output Production Capacity - 600 Kg/Hr. * Production Capacity :Output capacity is depends on the bulk density of Raw Material. So it will vary with different input raw material.It will be 400 Kg to 600 Kg/Hr. If the raw material is not in powdery form then Hammer Mill is required additionally.Electricity / Power : Total Connected power Load - Approx. 48 HP Practical used Amp. Load - Approx. 40 - 50 Amp Power consumption - Approx. 35 - 40 Unit/MT Individual Electric data : Briquetting Main Ele.Motor - 40 HP Feeding Kupy Ele. Motor - 5HP Screw Conveyor Ele. Motor - 2 HP Lubrication System Ele. Motor - 1 HP Area & Size : Foundation - 12 Feet x 4 Feet Machine Room (For one Machine) - Minimum 20 Feet x 15 Feet Total Area for Project - Minimum 200 M3 or More Silent Futures of Radhe Engineering Co. - Biomass briquetting Plant (Super-60) : Standard genuine parts with applicable MOC and process Compact but ideal design reference to Jumbo-90 Temperature sensors to all bushes to prevent life of bushes. Auto control feeding as reference to main motor load and auto restart VFD to screw conveyor to change speed of feeding

Biomass Briquetting Plant (Jumbo - 90)

Get Price Quote

Biomass Briquetting Plant

5,600 - 6,000 Per Ton

400 Tons (MOQ)

We sell only first quality

Biomass Briquetting Plant

5,800 - 6,500 Per Ton

Biomass Briquetting Plant

Get Price Quote

The biomass briquetting plant is completely eco-friendly technology. Briquettes from Agriculture and industry waste is a completely carbon free as made with binder less technology. The biomass briquettes are easy to maintain and transport. In India these product is more popular than other country. The biomass briquetting plant turns out to be a great substitute of coal. Owing to Subsidy for biomass briquetting plant in India, profit and success on this plant is great. Main concept of this project is to produce the material as a bio-coal.

Biomass Briquetting Plant

Get Price Quote

With the aid of state-of-the-art infrastructure facility, we have earned specialization in meeting the variegated needs of clients in an efficient manner. The implementation of advanced technologies ad latest production techniques enhances our capacity of production.Furthermore, we have appointed an adroit team of diligent professionals in our organization for managing the complete operation in a systematic manner. These professionals are young, enthusiastic and dedicated towards their work and meeting set organizational goals effectively. Due to their scrupulous efforts, we have attained an enviable position in the market.

Biomass Briquetting Plant

Get Price Quote

Due to the increase on cost of conventional fuel (such as coal, wood and natural gas) and the need for new energy resources, more people start to focus on Biomass fuel business. Biomass briquette is renewable, clean, eco-friendly energy, especially for agricultural countries.

Semi Automatic Briquetting Plant

100,000 Per Piece

1 Piece(s) (MOQ)

Biomass Briquetting Plant

Get Price Quote

Biomass renewable energy can be generated in a number of ways. Agricultural waste, industrial waste and forestry waste gathered and squashed under high pressure but without any binder so it is known as binder less technology. The Biomass Briquetting machineis the only way through which can make solid fuels.

Biomass Briquetting Plant

Get Price Quote

Biomass Briquette Plant

Get Price Quote

We are offering biomass briquette plant. re new able energy fuel. Pollution free because there is no any sulfur material.

Bio Mass Briquetting Plant

Get Price Quote

We offer Bio Mass Briquetting Plant. Biomass briquettes are a biofuel substitute to coal and charcoal. They are used to heat industrial boilers in order to produce electricity from steam. The most common use of the briquettes are in the developing world, where energy sources are not as widely available. There has been a move to the use of briquettes in the developed world through the use of cofiring, when the briquettes are combined with coal in order to create the heat supplied to the boiler. This reduces carbon dioxide emissions by partially replacing coal used in power plants with materials that are already contained in the carbon cycle. Manufacturers mainly use three methods to create the briquettes, each depending on the way the biomass is dried out. Although biomass briquettes are usually manufactured, biomass has been used throughout history all over the world from simply starting campfires to the mass generation of electricity.

Biomass Briquette Plant

965,000 Per Piece

Biomass Briquetting Plant

Get Price Quote

The biomass crusher cum shredder is a first priority product in biomass briquetting process as per it is accustomed for chop the biomass material into smaller particles and suitable size required by individual biomass briquetting plant. Our crusher for biomass briquetting plant offers defined product output, prescribed by the user and used with all types of biomass material

Bio Mass Briquetting Plant

Get Price Quote

Bio Mass Briquetting Plant, Agro Waste Briquette, White Coal, Briquette Coal

Biomass Briquetting Plant

Get Price Quote

We are established manu facturers and suppliers of biomass briquetting plant in ludhiana, punjab ram type briquetting machines manufacturers . We also suppliers of second hand biomass coal briquetting machines we deal in models 30mm to 100mm briquetting product size model no-production capacity-power requirement 40mm. ---- 250-300kghr---- 18hp 60mm ------ 900-1000kghr---40hp 70mm---- 1200kghr ---- 55hp 80mm ----- 1300kghr-- 70hp 90mm ------ 1500-1800kghr --- 87hp 100mm ---- 2000-2500kghr --- 89 hp

Biomass Briquetting Plant

Get Price Quote

Biomass Briquetting Plant, Animal Feed, Biomass Briquette Press

Biomass Coal Briquetting Plant

Get Price Quote

Biomass Coal Briquetting Plant, Biomass Briquetting Plant