Small Biomass Gasifier

Get Price Quote

In our warehouse, we store the entire lot under a safe environment and our unit is facilitated with all required amenities ensuring complete safety of the products from different kinds of damages. Located in Ghaziabad(India), the company has gained immense prominence in the domestic market owing to its fair pricing policy and professionalism. Features : Easy to ignite & operate Fuel efficient Long working life Multi burner operation possible

50KVA Biomass Gasifier

4,989,000 Per Piece

1 Piece (MOQ)

Best Deals from Biomass Gasifiers

10 kW Small Biomass Gasifier

340,000 - 1,000,000 Per Piece

1 Piece (MOQ)

URJA BIOMASS GASIFIERS

Get Price Quote

1 Set (MOQ)

URJA” Biomass Gasifier is a thermochemical catalytic Converter/Reactor where various physical & chemical reactions take place. Biomass is passed through various Zones – Drying/ Distillation Zone, Pyrolysis Zone, Combustion Zone & Reduction Zone. When the biomass is passed through all the above Zones, it gets converted into a high quality combustible gas called Producer Gas, which is a low caloric, low pressure gas that can be combusted for low cost Heat & Power generation etc. Salient Features High Conversion efficiency from solid Biomass to gaseous fuel 85% in hot gas mode. Each Kg of Biomass Producer 2.5 m3 of gas having an average calorific value of 1050 Kcal / m3. 1 liter of diesel fuel can be saved from 4Kg of wood or 5Kg of Rice Husk. Advantages of Installation "Urja" Biomass Gasifire Low cost Power Generation [ 65% - 85% diesel saving in DG Set / Engine ] Pollution Free & reduces Green Houses Gas Emission & Acid rain. Waste Management Benefits

Phoenix Biomass Gasifier

Get Price Quote

Wood Biomass Gasifier

Get Price Quote

Biomass Gasifier specially developed for industrial heating applications having a heat output of 12,50,000 KcalHr. Suited for Boilers, Rotary melting furnaces etc.,

Biomass Gasifiers

Get Price Quote

We are manufacturing biomass gasifiers for power generation as well as for thermal applications. We are manufacturing these gasifiers for 20kwe to 1200 kwe capacity. We are manufacturing these gasifiers under joint venture with teri and have supplied our gasifiers to canada, usa, romania, thailand and finland

Biomass Gasifier

Get Price Quote

These Biomass Gasifiers are power efficient and have the higher performance rate. Place an order with us for acquiring top-of-the-line quality Biomass Gasifier in retail or bulk. We are supported by a well-structured warehouse that assists us wholly in keeping the lot safe and meeting urgent requirements at a time. Also, we keep it updated on regular basis.

Biomass Gasifier

1,000,000 - 25,000,000 Per Piece

1 Piece (MOQ)

Biomass Gasifier

Get Price Quote

Downdraft Biomass Gasifier

Get Price Quote

In Downdraft Gasifier System, the controlled intake of air (oxygen) is fed into the chamber containing downward movement of biomass material. After going through the process, the producer (inflammable) fuel gas is finally collected and drawn off at the bottom of this Gasifier. It is an efficient technique which has the capacity to process the biomass containing the moderate moisture (up to 30%). About 5 to 10 minutes time is needed to ignite the combustion and bring the plant to an operative temperature. Downdraft Gasifier is best suitable for the applications where the temperature control is critical, and the cleaner fuel gas is required. These Gasifiers can be used in those applications where moderate temperature is required up to 1100oC.

Biomass Gasifiers

Get Price Quote

Biomass gasification is a process of converting solid biomass fuel into a gaseous combustible gas (called producer gas) through a sequence of thermo-chemical reactions. The gas is a low-heating value fuel, with a calorific value between 1000- 1200 kcal/Nm3 (kilo calorie per normal cubic metre).

Biomass Gasifier

Get Price Quote

We provide our clients with good quality Biomass Gasifier. It undertakes the process of converting solid biomass fuel into combustible gas through thermo-chemical reactions. It is efficient for biomass gasification process and is highly reliable for their working. Use The gas produced is low heating value fuel; possessing calorific value of 1000-1200 Kcal/Nm3. 1 kg of air-dried biomass produces 2.5-3 Nm3 of gas through gasification. Gas Composition Carbon monoxide -20-22%Hydrogen (H2O)-15-20%Methane(CH4)-2-3%Carbon dioxide (CO2)-9-11%Nitrogen(N2)-45-54%Water vapor (H2O)-10-15%Heavy hydrocarbon-0.2-0.4%Â Used In OvensBoilersKilnsHot air generatorThermic fluid heaters for thermal applications Features Appropriate designGood conversion efficiencyBetter control on burningProduction of clean flue gases in the exhaustLow investmentReduction in deforestationReduction in Diesel/Kerosene/Furnace Oil/ LDO costCapable of withstanding high temperatures up to 1860 degree centigradeNet zero CO2 emission

Biomass Gasifiers

630,000 Per Piece

1 Piece (MOQ)

Customer Requirements

Biomass Gasifiers

200,000 - 5,000,000 Per

We are offering pellet stove, pellet gasifier, biomass gasifier. Pellet gasifier is a system which converts biomass pellets into gaseous form. This gas is stored in a compressor which can be used for cooking which will be as convenient as using lpg.

Biomass Gasifiers

Get Price Quote

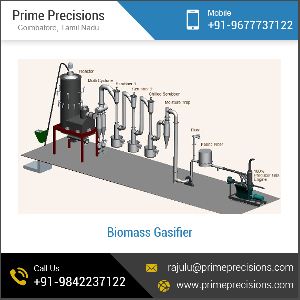

Hi I am Rajendran from coimbatore, also we manufacture Bio MASS gasifier for various thermal purposes and char coal making machines etc For a y requirements plz contact . REGARDS Rajendran

Biomass Gasifier

Get Price Quote

Specifications Gas after filteration is feed to engine. Problem addressed: There are lots of villages in the country which are still not electrified or are receiving power erratically. Given the limited global supply of fossil fuels, search for renewable energy has been on the top of the sustainability agenda. Biomass gasification, a century old technology, is viewed today as an alternative to conventional fuel. In gasification process, wood, charcoal and other biomass materials are gasified to produce so called producer gas for power or electricity generation. Mr Rai Singh Dahiya observed that the users of biomass gas (producer gas) as a fuel generally complain about choking in the engine after running for a certain period of time. He solved this problem Product: The innovator has changed the conventional design of gasifiers specially the filters and cooling units to get clean gas and ensure smooth operation of engineat low operational cost. It is a down draft typebio mass gasifier, compact and efficient system for converting Bio Mass into producer gas which is used as a fuel in running Diesel Engine by making little modification on engine. The Biomass is burnt in a furnace packed from all the sides and having one outlet to pass the gases to other chamber where these gases are cooled and then passed through the filter for filtration. This filtered gas is then feed to the engine, as a substitute to diesel or like other fuel, for its running. Technical specifications : Capacity-5kw to 50 Kw, Three Phase, P.F. 0.8, water cooled, Two Cylinder, four cylinder, six cylinder and eight cylinder Self Start, Alternator with complete standard accessories (without Battery).

Biomass Gasifier

Get Price Quote

We are offering Biomass Gasifier. Biomass Gasifier is an excellen Solution for Community Cooking. It Works on firewood and Briquettes with thermal Efficiency in the range of 40-50 %. Smoke only at start, just for 5-10 minutes. Once clean flame is achieved, it can be run for any number of hours without constant attention, so more time for other activities. It can be used for Roti making, Boiling, Frying etc. Minimum Maintenance i.e cleaning of tar from gas pipe once in 2-3 months. Available in two burners design also. Payback period is approx.500 hours(2-6 months). Life is approximately 10 years. As Briquettes are made from waste biomass; hence it helps for waste management too. Thermal Efficiency in the range of 40-50 % Smoke only at start, just for 5-10 minutes Used for Roti making, Boiling, Frying etc. Minimum Maintenance Payback period is approx.500 hours(2-6 months) Life is approximately 10 years

Biomass Gasifier

Get Price Quote

Biomass Gasifier

3,500,000 Per unit

Biomass Gasifiers

Get Price Quote

1 Piece(s) (MOQ)

Chanderpur Works Pvt. Ltd. is a leading designer, manufacturer and supplier of Industrial Gasifier, Industrial Biomass Gasifiers, Coal Gasifiers and gasification based power plants for thermal and electrical applications. We are manufacturing thermal Gasifiers under Technical Collaboration with "TERI" (The Energy & Resource Institute, New Delhi). Chanderpur Works Pvt. Ltd. is now offering " CE " Marked Gasifiers. We have supplied more than 70 Gasifiers of different capacities for rural, industrial and urban projects. Our biomass gasifier technology is approved by Ministry of Non-Conventional Energy Sources (Government of India) and also tested & approved by Indian Institute of Technology, New Delhi and Mumbai. We are also undertaking the thermal projects as well as providing power production from agricultural waste technology and are also one of the leading coal mill manufacturers in India.

Biomass Gasifiers

Get Price Quote

bio mass gasifier

6,000,000 Per unit

Biomass Gasifier

Get Price Quote

Nath Motors provides clean energy generation through biomass gasification.Biomass Gasifier is a thermo-chemical reactor where Biomass gasification takes place which is a conversion of solid fuels(Wood & Agricultural waste etc) into a combustible gas mixture normally called "Producer gas".Due to rapid industrialization and the burning of fossil fuels all over the world lead to emission of CO2. Contributes 50% of green gas emission One of the remedies to limit the rising content of CO 2 in the atmosphere is energetic use of biomass fuel. Biomass is basically an organic material, which includes wood, crop residues, solid waste, animal wastes, sewage, and waste from food processing. Biomass is Your browser may not support display of this image. made up of mainly carbon and hydrogen. Advantage GasificationIn this process, biomass is converted into a mixture of gases through a thermo-chemical reaction called producer gas consisting of combustible gases mainly hydrogen, carbon mono oxide and methane, non-combustible gases nitrogen, carbon dioxide and water vapor. The essence of gasification process is the conversion of solid carbon fuels into carbon monoxide by thermo chemical process. The gasification of solid fuel is accomplished in air sealed, closed chamber, under slight suction or pressure relative to ambient pressure This technology enables you to directly treat Green Wood / Biomass having moisture content of 10-15% without using a drying process. Biomass gasification is completed in many stages that elaborated and explained with a flow diagram given below Drying : Biomass fuels consist of moisture ranging from 5 to 35%. At the temperature above 100 o C, the water is removed and converted into steam. In the drying, fuels do not experience any kind of decomposition. Pyrolysis : Pyrolysis is the thermal decomposition of biomass fuels in the absence of oxygen. Pyrolysis involves release of three kinds of products such as solid, liquid and gases. The ratio of products is influenced by the chemical composition of biomass fuels and the operating conditions. The heating value of gas produced during the pyrolysis process is low (3.5 - 8.9 MJ/m 3 ). It is noted that no matter how gasifier is built, there will always be a low temperature zone, where pyrolysis takes place, generating condensable hydrocarbon. Oxidation : Introduced air in the oxidation zone contains, besides oxygen and water vapors, inert gases such as nitrogen and argon. These inert gases are considered to be non-reactive with fuel constituents. The oxidation takes place at the temperature of 700-2000oc. Heterogeneous reaction takes place between oxygen in the air and solid carbonized fuel, producing carbon monoxide. Plus and minus sign indicate the release and supply of heat energy during the process respectively C + O 2 = CO 2 + 406 [ MJ/kmol] In reaction 12.01 kg of carbon is completely combusted with 22.39 m3 of oxygen supplied by air blast to yield 22.26 m 3 of carbon dioxide and 393.8 MJ of heat. Hydrogen in fuel reacts with oxygen in the air blast, producing steam . H 2 + ½ O 2 = H 2 O + 242 [ MJ/kmol] Reduction In reduction zone, a number of high temperature chemical reactions take place in the absence of oxygen. The principal reactions that takes place in reduction are mentioned below. Boudouard reaction - CO 2 + C = 2CO - 172.6 [MJ/kmol] Water-gas reaction - C + H2 O = CO + H 2 - 131.4 [MJ/kmol]Water shift reaction - CO 2 + H 2 = CO + H 2 O + 41.2 [MJ/kmol]Methane production reaction - C + 2H 2 = CH 4 + 75 [MJ/kmol] From above thermo-chemical reaction it may be understood that heat generated in pyrolysis is absorbed in reduction process. Hence, the temperature of gas which is very high in the beginning goes down as it passes through various stages. If complete gasification takes place, all the carbon is burned or reduced to carbon monoxide, a combustible gas and some other mineral matter is vaporized. The remains are ash and some char (unburned carbon). Advantage Gasification It saves upto 73% of fuel cost when compared to conventional fuel options Low initial investment and cost of power production Applied over a range of output ratings (5KWe to 2Mwe) with flexuble process control Range of ApplicationsPower Generation: Round the clock Power Generation Pumping and Irrigation Village electrification Captive power(industries) Grid -fed power from energy plant installed on wastelands Thermal Applications Hot Air Generators Dryers Boilers Thermic Fluid Heaters Ovens Furnaces & Kilns Gasification for Energy Supply Rural areas in the developing countries India are characterized by disperse population and a lack of infrastructure. Energy is the basic mean in improving the living standard and productivity. Energy is required in household for lighting and running electrical apparatus such as TV and Radio. Energy is also demanded in agriculture for operating irrigation pumps and other machinery such as thresher.

Biomass Gasifiers

Get Price Quote

Biomass gasifier Biomass materials are used since millennia for meeting myriad human needs including energy. Main sources of biomass energy are trees, crops and animal waste. Among the biomass energy sources, wood fuels are the most prominent. Presently, the biomass sources contribute 14% of global energy and 38% of energy in developing countries. Biomass gasification has some better advantages over other alternative energy sources. The technology's conversion efficiency is high. It can be applied over a wide range of output metrics with only a small variation in overall efficiency and investment.

Biomass Gasifiers

Get Price Quote

Agricultural activities generate large amounts of biomass residues. Crop residue, traditionally considered as “ trash’or agricultural waste, is increasingly being viewd as a valuable resources. Corn stalks, corn cobs, wheat staw, and other leftovers from grain production can be used as feedstock in our biomass gasifier system.

Biomass Gasifiers

Get Price Quote

Damodar is associated with 'Ankur' Scientific Energy Technologies for marketing, installation and after sales services of Biomass Gasifier. Damodar also undertakes long term O&M contracts for these plants. Till date Damodar has installed more than 90 Gasifiers across the country.

Biomass Gasifiers

Get Price Quote

Fixed bed updraft gasifier when supported with cyclone separator, wet scrubbers, bag filters, electrostatic precipitator etc. can deliver clean producer gas which can be used to fire I C Engines which in turn can generate electric power when coupled with generator.

Biomass Gasifier

Get Price Quote

We are leading manufacturer and supplier of Biomass Gasifiers, Coal Gasifiers and gasification based power plants for thermal and electrical applications. A Biomass Gasifier converts solid fuel such as Wood Waste, Saw Dust briquettes and agro-residues converted into briquettes into a gaseous fuel through a thermo-chemical process and the resultant gas can be used for heat and power generation applications. The overall thermal efficiency of this process is more than 75%. The combustible gas mixture, known as 'producer gas', typically contains carbon monoxide (20% - 22%), hydrogen (12% - 15%), nitrogen (50% - 54%), carbon dioxide (9% - 11%) and methane (2% - 3%). The producer gas has relatively low calorific value, ranging from 1000 to 1100 kCal.Nm3 (5500 MJ/Nm3). Advantages Low Cost : 4 Kg. biomass replaces 1 liter petro-fuel. You can easily find out the per day savings b installing the biomass gasifier. Extremely Clean Fuel : If you compare the emissions from the petro-fuels with the emissions from producer gas, you will found SO2 free emission from gasifier. Reduces wood consumption up to 50% for institutional & industrial application, where still wood is being used for thermal application Environmentally sound technology Easy to operate and maintain Provides energy security Generates local employment Replace the fossil fuels. Being renewable energy product, gasifiers are eligible for Carbon Credits under CDM mechanism.

Biomass Gasifiers

Get Price Quote

Biomass Gasifiers, Bio Gas Generator, Electronic Panel, Acoustic Enclosure