Sonic Soot Blower 240 HZ

60,000 - 100,000 Per piece

1 Piece (MOQ)

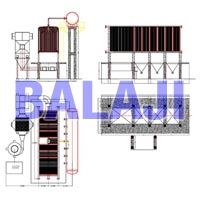

WHAT IS SONIC SOOT BLOWERS? Sonic soot blowers are an acoustics automatic online cleaning systems for boilers, super heater, economizers, air-pre heaters, dust collectors, bag filters, etc. The system comprises of high intensity at low frequency sonic soot blower powered by compressed air pressure of 5-6 kg/cm2 and are engineered &designed to prevent particulate buildup on the tubes, which significantly improve equipment efficiency. What is the basic principle that sonic soot blower works on? Sonic soot blower depends on the principle of kinetic activation of residue particles, utilizing sound waves produce by sound generator and work by compressed air. Micro processor based controller controls the total activity of system. Working of sonic soot blower The basic principle of the system is that the sound waves of high intensity with particular frequency which generate flow over various surfaces It produces sound waves of 140 dB at particular frequency If any kinetically activated dust particles are clanged to any solid surface then they are been reverberated and becomes break liberated from that surface.??? Once dislodged, these particles fall due to gravity or fly away in the flue gas It is activate for 10-20 sec after every 15 minutes to 30 mins automatically, depending upon the soot/dust load on the surfaces of the equipment. Insert some best picture of sonic soot blower, YouTube link of specific video of sonic soot blower and attach the catalog. Advantages of sonic soot blower over the other cleaning system Elimination of murkiness spikes because of more standard, more productive cleaning Guaranteed not to harm tube structure or tube bundles Elimination of tube erosion and corrosion problems by steam cleaning 360° cleaning of all pipe surfaces – not harsh leading edge tube cleaning as with steam soot blowers Prevention of debris develop and sintering on tubes because of more powerful activities of sonic soot blowers No expensive repair, maintenance or operational costs. Benefits One time installation Best to control pollution Increased equipment service life Lower operating cost Low maintenance Effective cleaning Fully automatic operation Continuous cleaning Reduced the frequency of Boiler maintenance. Use of sonic soot blower guarantees that there will no damage to tube bundles and structure Use of sonic soot blower will prevent of ash build up and sintering on tubes due to more effective operation It will eliminate tube corrosion and erosion problems caused by water/steam cleaning regimes There will no costly repair, maintenance or operational costs. Sonic Soot blower is based on the principle of kinetic activation of the dust particles, using sound waves generated by a sound generator, operated by compressed air. a microprocessor-based programmer controls the complete operation of system Elimination of opacity spikes due to more regular, more efficient cleaning Guaranteed not to damage tube bundles or structure Elimination of tube corrosion and erosion problems caused by water/steam cleaning regimes 360° cleaning of all tube surfaces – not harsh leading edge tube cleaning as with steam soot blowers Prevention of ash build up and sintering on tubes due to more effective operation of Sonic Soot Blowers No costly repair, maintenance or operational costs.

boiler mountings

Get Price Quote

Our company stands tall among the eminent Manufacturers, Suppliers and Exporters of Boiler Mountings. These are fabricated at highly sophisticated manufacturing units by using latest process technology. We offer the Mountings in varied specifications as per the specific requirements of the buyers. Buyers can obtain these at reasonable rates.

Best Deals from Boilers

rice boiler

20,000 - 40,000 Per Piece

In order to ensure zero damage during transit, we have adopted modern facility for meticulously packaging our offerings. And, we also ensure that the used material is of high quality. We believe in utilizing government approved and reputed payment methods in order to maintain a high level of transparency and trust while a patron is paying for an order.

Boiler Stainless Steel Needle Valve

550 Per Piece

10 Piece (MOQ)

Vacuum Ironing Tables And Boiler

34,500 Per Piece

1 Piece (MOQ)

Electric Boiler

Get Price Quote

electric boiler

Pradeep Milk Boiler - 5L

10,000 Per Piece

1 Piece (MOQ)

21 Kw Stainless Steel Steam Bath Generator

30,000 - 40,000 Per Unit

1 Unit (MOQ)

100 kg/hr Wet Back Boiler

3,000,000 Per Piece

1 Piece (MOQ)

Hot Water Boiler and Steam Boiler

Get Price Quote

1 Piece (MOQ)

Hot Water Boilers and Steam Boilers We design and manufacture hot water and steam boiler of outstanding quality in cost effective mode that meet the modern day requirements of the industry. This generating system essentially comprises of a fully automatic reverse flame package type steam generator, which includes membrane type helical coil integral combustion chamber accommodated in SS/MS/Copper and insulated shell. The hot fuel outlet is connected to smoke tube preheated to preheat feed water. The feed water pump, blower, fan, fuel pump are mounted on common base frame. This boiler is highly efficient and can be easily installed and dismantled.

Bronze Steam Injector Square Body

Get Price Quote

We are offering bronze steam injector square body. Automatic self acting & restarting operation.

Electrode Steam Boiler

200,000 Per Piece

1 Piece (MOQ)

Dairy Ghee Boiler Operated

450,000 Per Piece

1 Piece (MOQ)

Boiler Tubes

Get Price Quote

We are offering boiler tubes m.s.erw boiler tubes as per bs 3059 part I erw gr.320 ibr bs 3059 part ii erw gr.360 ibr I s 1914 part I -v gr.erw 320mtc m.s.erw airpreheater tubes as per bs 6323 part I - part 5 mtc.

Horizontal Steam Boiler

Get Price Quote

rice boiler

59,799 - 93,000 Per piece

1 Piece (MOQ)

Single Drum Boiler

1,000,000 - 20,000,000 Per Piece

1 set (MOQ)

Maxgreen Ecoenergy Pvt. Ltd. is a popular name in the industry, trusted for its high quality Single Drum Boiler. We are widely acknowledged as reliable Single Drum Boiler Manufacturer, Exporter & Supplier. We use only premium grade raw materials to manufacture this variety of boiler. Our Single Drum Boiler is preferred for its corrosion resistance and rust resistance. We offer Single Drum Boiler in different sizes and capacities.

Oil Fired Steam Boiler

3,000,000 Per Piece

1 Piece (MOQ)

Air Swirl Burner

4,500 Per Piece

3 Piece (MOQ)

Air Swirl Burner is a type of burner primarily used in industrial combustion systems. It is designed to produce a swirling flow of air and fuel to achieve efficient combustion with low emissions. The swirl motion of the air helps in mixing the fuel with the air and creates a stable flame. Apart from that, Air Swirl Burner consists of a central fuel injector and several air swirler vanes mounted around it. The fuel is injected into the swirling airflow and mixed thoroughly, promoting efficient combustion. The air swirler vanes are movable and adjustable to control the size and shape of the flame.

High Pressure Gas Train

Get Price Quote

We are here to guide our clients with the secure payment procedures. With us, the customers get convenience to pay through both online and offline payment methods Catering to the varied demands of the customers, we ensure that the offered array of products is as per the exact customers' demand and need.