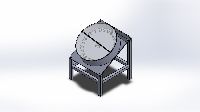

Automatic Bottle Unscrambler

Get Price Quote

We are ranked among well-known Manufacturers, Exporters & Suppliers of a wide array of Automatic Bottle Unscramblers. Made with superior-grade raw materials, our entire range of Automatic Bottle Unscramblers is high performance, dimensionally accurate, durable and reliable. Interested customers can purchase Automatic Bottle Unscramblers from us in bulk. We offer individually tailored Automatic Bottle Unscramblers as well and make timely delivery. Product Details : Structure - Round plate and many sections of bottle unscrambling belts, automatically feed the bottles if there are not enough empty bottles, automatic stop if the bottles are full. Application - Can arrange the disordered empty plastic bottles into good order Highest Speed - 200 bottles/min. Do not need to change the mold when changing different size of bottles. Only need to adjust the space according to the marks Saves energy and raises capacity. Automatic stop prolongs the lifetime of the machine

Bottle Unscrambler Machine

12,000,000 Per Piece

1 Piece (MOQ)

Best Deals from Bottle Unscrambler

Bottle Unscrambler

Get Price Quote

Owing to our state-of-the-art manufacturing unit, we hold expertise in producing highly advanced Bottle Unscrambler. The Bottle Unscrambler, we provide, is advanced bottle unscrambling equipment that has specially designed Torque limit art for the main motor reducer to protect the machinery. Manufactured by the competent engineers, the Bottle Unscrambler is highly efficient, reliable, & versatile. These features make the Bottle Unscrambler suitable for production at packaging industry. Details To avoid overturn in delivery, the neck of the bottle is locked through air conveyor. An alarm with locker detector is installed that automatically stops the machine. Two put-casts in on cycle ensure that every work location should be with bottle, which enhance bottle out efficiency A photoelectric witch is set for starting when there is no bottle and stopping

Automatic Bottle Unscrambler

Get Price Quote

Silent Features : S.S. 304 anodizing aluminum construction. Smooth in feeding for existing packaging line. Totally enclosed machine. Automatically correct inverted bottles. Easy to operate and vibration free. Ensure no inverted bottles go to the next machine. Running with high efficiency, no need workers watching. Simple in structure. Easy to clean and maintain. Optional Features : Low level alarm in storage of container. Elevator speed control sensor. Acrylic or Poly carbonate enclosure in frame. Online ionized air cleaning. Accumulation conveyor turn table of unscrambled containers. Container counting. Online container testing by leak test, weight test, etc. Online labeling.

Unscrambler Machine

Get Price Quote

Bottle Unscrambler

Get Price Quote

Our bottle unscrambling machine suitable for any kind of round and flat bottle with speed 60 BPM to 300 BPM , Pharmaceutical bottle bottle unscrambling machine, neutraceutical bottle unscrambling machine, cosmetic bottle unscrambling machine, personal care and specialty chemicals , Dairy ,Bottled Water etc. Our SB-6, SB-10 and SB-15 are linear bottle unscrambling machine specially designed to provide oriented bottle to the bottle filling and Jar packaging production line. SB series are Unscrambles machine positioning bottles vertically before they reach the filling line. Technical Specification of Bottle Unscramble Machine

High Speed Bottle Unscrambler

Get Price Quote

1 Set(s) (MOQ)

The bottle unscramblers operate with great simplicity, accuracy, efficiency, and minimal maintenance. The unit is suitable for large variety of shapes and sizes of bottles. bottle unscrambler is controlled electronically with perfect synchronization with the next packaging line. Owing to this, the offered range is known to have a superior performance and a longer service life. In addition to this, the offered range marked at the most reasonable rate possible , is highly acclaimed and and almost labour saving.

Automatic Bottle Unscrambler

Get Price Quote

The Automatic Bottle Unscrambler is suitable to connect with any machine for uninterrupted feeding of bottles with speed up to 100 Bottles per minute depending on Bottle diameter and height. Unscrambler transfer bottles directly from Loading Hopper to infeed conveyor of any machine in vertical position. Machine is mainly suitable to connect with Bottle Air Jet cleaning machine shown in the layout for used in Bottle packing line. Machine can be used for feeding of Plastic or PET Bottles, Jars etc. Machine suitable for use on products like Dry Syrups, and Bulk Packing of Tables and Capsules. Machine in Stainless Steel Finish with all contact parts in SS316 and Nylon Materials. Machine also having overload clutch system to prevent jamming during the operation. The manifold comprises of inner nozzles which jets compressed air in the bottle and an outer socket, which cover the mouth of the bottle and is connected to an exhaust, ensures perfect cleaning. SPECIAL FEATURES: Fully Stainless Steel Finish Simple Change over for different size of Bottles Overload Clutch for Jamming A.C. Variable Frequency Drive System.

Inline Unscrambling Machine

Get Price Quote

Appliction » To Orient Plastic bottles » Bottle Dia :-30-100mm » Bottle height:-30-150mm Competencies » Total CGMP model » Frame Made from SS-structure » Sleek sturdy and compact design » All controls from the panel. » Left to right and right to left options available » PLC HMI-Touch screen Features » Very few change parts required based on size of the bottles. » Special feature of Overload clutch, overload of rotary feeder is available » Rotary feeder feeds the bottle on the orienting device » In orienting devices only bottles oriented with neck in front will be inverted using loaded metal obstacle » Post that all bottles are re-inverted for conveying to next machine » Air rinsing with ionised air and vacuum online (optional) Utilities » 415V, 3-phase, 50hz electric supply » Electric load:- 3HP » Air:- 3 CFM @ 4 to 6 kg/cm2 *The output of the machine depends on bottle geometry. * Specification subject to change without prior notice.

Automatic Bottle Unscrambler

Get Price Quote

Bottle Unscrambler

Get Price Quote

Bottle Unscrambler

Get Price Quote

1 Piece (MOQ)

the techno bottle unscrambler unit is designed with an aim to reduce man power and increase productivity of a plant. 1.the bottles are first dumped in the rotary conveyor/hopper with elevator 2.the bottles are then automatically transferred to the unscrambler unit by the intake conveyor. 3.the bottles are then oriented by the orientation unit. 4.the standing bottles then exit the conveyor via the exit conveyor. the techno unscrambler can be used for automatic feeding of container directly in to the filling, labeling, inspection line various shapes and size of container possible i.e. From 50ml-1ltr., shapes such as round. rectangle, oval etc. machinery features tool less operation drive setting through hmi. recipe saving option for each sku. sensors given for detecting bottle jam. linear interpolation based out feed system optional sponge coated belts for scratch free operation. stainless steel hopper and pre feeder to avoid contamination. optional covering available.

Rotary Unscrambling Machine

Get Price Quote

*The output of the machine depends on bottle geometry. * Specification subject to change without prior notice. Application: To Orient Plastic bottles competencies : Total CGMP model Frame Made from SS-structure, with height adjustment Sleek sturdy and compact design Control of air pressure, vacuum, speed of all drives from the panel itself. Left to right and right to left options available PLC HMI-Touch screen Features : Fast changeover of change parts as per bottles. Rotary Mechanism Special feature of Overload clutch, overload of turntable is available Only straight bottles are inverted using metal guide-rods hence all bottles are oriented Post that all bottles are re-inverted for conveying to next machine Features Special CAM Design instead of RODs for Bottle handling during inversion-reinversion process Air rinsing online with ionised air Production counter PLC-HMI touch screen Utilities required 415V, 3-phase, 50hz electric supply Electric load :- 5HP

Pet Bottle Unscrambler

Get Price Quote

Automatic Bottle Unscrambler

Get Price Quote

We provide a wide range of automatic bottle unscrambler.

Bottle Unscrambler

Get Price Quote

1. The machine is our own designed and manufactured product which is at the base of introducing advanced international technology and combining industry character of India. It is stable, independable and strongly adaptable.2. It can be changed according to client’s different requirement to the bottles3. Easy operation, fully automatic, with PLC control to adjust the frequency to synchronize with the whole line.4. Bottle exit is controlled by the synchronous belt and star wheel to ensure stable bottle exiting and no scrambling bottles and crushing.

Bottle Unscrambler

Get Price Quote

Laxmi Pharmamach Automatic Plastic Bottle Unscramble unit. For Arranging the Plastic Container whether it’s Round or Flat shape bottle in vertical position and can be aligned with online filling activity. It’s widely used in Pharmaceutical, herbal and Cosmetic Industries.

Bottle Unscramblers

Get Price Quote

The Bottle Unscramble Unit has been specifically designed to reduce man power and increase the productivity of a plant. The Techno-Unscrambler Unit 100-H, ideal for round and oval bottles consists of 6 major stations. The Process: The bottles are first dumped manually on to the Hopper The bottles are then moved to the rotary conveyor through the transfer conveyor at regular time intervals The rotary bottle feeder then continuously moves the bottles onto the intake conveyor of the unit The bottles then pass through the 2-orientation stations wherein they get oriented based on their shapes and filling station requirements A transfer system is then used to transfer the bottles from the unscrambler exit conveyor to the filling machine intake conveyor

Bottle Unscrambler

Get Price Quote

*The output of the machine depends on bottle geometry. * Specification subject to change without prior notice. Application: To Orient Plastic bottles To Orient Plastic bottles Bottle Dia :-30-100mm Bottle height:-50-150mm

Bottle Unscrambler

Get Price Quote