bread baking plant

Get Price Quote

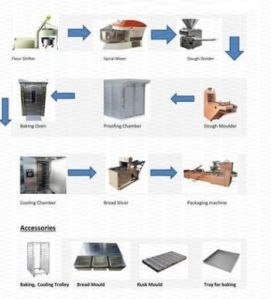

From the Desk of Viren Prajapati, Project Engineer for Bhagwani Bakery Machines Standard Basic Information on Initial Rusk Plant Start-Up, It’s best of our knowledgeFlour Shifter ( Optional ) : To sieve flour Spiral Mixer 80Kg : To mix flour, water, suji, ghee, preservatives, improvers, oil, yeast (for fermentation process) and other ingredients Dough Divider ( Optional ): To Divide Dough Dough Moulder : To Mould Dough in Shape of 10 inches long and then to place in the Mould Proover (Optional): For Quick Fermentation Process Rotary Rack Oven 44Tray Diesel Operated : To Bake Processed Dough at 230 C Temperature Rusk Slicer : To Slice the Rusk Accessories : Table, Trolley, Tray and Mould When business prosperous you need additional addition in the infrastructure 3000 Sq Feet Place with One Oven, Proover, Shifter, Cooling Tunnel, High Speed Slicer, Packing Machine. Generator is Compulsory. First Aid and Fire Safety should always been concerned. Food Safety standards should be followed. Lab is essential in Bread Factory.

bread baking plant

500,000 Per Piece

Best Deals from Bread Baking Plant

Bakery Plant

Get Price Quote

50 KILOGRAMS (MOQ)

Shortening is any fat that is solid at room temperature. the reasons it is called shortening is that it prevents cross-linkage between gluten molecules. Cross linking gives dough elasticity. In pastries such as cake, which should not be elastic, shortening is used. Although butter is solid at room temperature and is frequently used in making pastry the term “shortening” seldom refers to butter but is more closely related to margarine.Fostechno offers bakery shortening plant which is designed to meet International Standards.A common method for production of margarine today comprises of emulsifying a blend of vegetables oils and fats which can be altered using fractionation, interest erification along with hydrogenation or cutting edge interest erification by enzymes. This process is conducted with dairy or non-dairy ingredients. The mixture is cooled till it becomes solid and then processed to improve its texture.Contemporary margarine types can be produced from many vegetable fats. Commercially available margarine can range from 70 to 85 % fat content.

bread baking plant

Get Price Quote

Dough Proofer Machine

48,000 Per Piece

bread baking plant

Get Price Quote

Bread Bakery Plants

Get Price Quote

Bakery Plant

Get Price Quote

Bakery Shortening Margarine is a Fat modification Process to get the desired Fat for crispy Fluffy and delicious Bakery Product. Muez-Hest offers Bakery shortening Margarine Plant which is designed to meet International Standards. The main salient Features which we provide with our Plants are • Complete Formulation Recipe • Flexible Pipe line arrangement for different application. • Combination of oils, based on availability of oil in Existing Plant the main salient options that we offer with our plants area unit • complete formulation instruction • versatile pipe line arrangement for various application. • combination of oils, supported availableness of oil in existing plant.

Bread Baking Plants

1,500,000 Per Piece

bread baking plant

1,500,000 Per Piece

1 Piece (MOQ)

bread baking plant

Get Price Quote

bread baking plant

Get Price Quote

bread baking plant

bread baking plant

Get Price Quote

bread baking plant, Biscuit Baking Plant, biscuits baking plant

bread baking plant

Get Price Quote

bread baking plant, Leather Goods, Pulses, Agarbatti, hand tools

bread baking plant

Get Price Quote

bread baking plant, Biscuit Baking Plant, Deck Oven, Chocolates, hand tools

bread baking plant

Get Price Quote

bread baking plant, Automation Panel, Phosphating Plants, biscuit plant

bread baking plant

Get Price Quote

bread baking plant, Biscuit Baking Plant, Chocolates, Deck Oven, hand tools

bread baking plant

Get Price Quote

bread baking plant, Biscuit Baking Plant, Deck Oven, hand tools

bread baking plant

Get Price Quote

bread baking plant, Sugar Handling System, Soft Dough Making Machine

bread baking plant

Get Price Quote

bread baking plant, Rotary Rack Ovens, Spiral Mixers, Planetary mixer