Bread Baking Oven

Get Price Quote

Bread baking oven made available by us is well recognized in the bakery industry for delivering smooth and consistent performance standards in both normal working as well as in demanding working conditions. Here, the oven is made available in dimensions (in mm - external) of 2130(w) x 1730(d) x 2400(h) mm 84”(w) x 69”(d) x 95”(h) with minimum dimensions to take oven comprising (h x w) 2500(h) x 970(w)mm100” x 39”. Further, these are made available in maximum operating temperatures of 300 °c with connected load of 2.75 kw (4 hp) (415 vac, 50 hz) and weight of 1950 kg. With tray size of 450 mm x 700 mm (18” x 27”), the working capacity of bakery oven b-1300 on a per batch basis comprise bread 400 gm (336 loaves -2 trolleys x 14 shelves), sponge cake (106 kg - 2 trolleys, 28 trays), buns 45 gm 864 nos - 2 trolleys, 36 trays), biscuits (40 kg - 2 trolleys, 36 trays), dry rusk (36 kg - 2 trolleys, 36 trays) and khari (24 kg -2 trolleys, 36 trays). We work with the vision of successfully catering to specific baking process needs of bakeries and offer our customers exceptional performance oriented as well as technologically advanced and functionally superior range of ovens as well as bakery machinery products. Here, our rich as well as in-depth experience in the field of baking equipment allows us to maintain manufacturing standards in sync with those followed internationally.

Bread Baking Oven

250,000 Per Piece

Best Deals from Bread Oven

Commercial Bread Oven

6,500,000 Per Piece

Bakery and Hotel Ovens

Get Price Quote

Baking Ovens for Breads, Biscuits, Cakes, Cookies etc. Available in M.S. S.S. Temperature 3000C Sturdy welded Construction with Counter balanced doors, S.S. Tubular heaters proportionally mounted on top and bottom of deck for even heat. Individually controlled heaters. Control panel of thermostate, contactor, pilot lamp and separate heat switch.

Rotary Bread Oven

300,000 Per Piece

bread rotary oven

Get Price Quote

bread rotary ovenfiring chamber: the complete firing chamber will be insulated with mineral wool filled from out side to conserve heat and increase efficiency. The firing chambers shell fabricated out of stainless steel. The oven can maintain temperature up to 350? and temperature rises from room temperature to 225? in just 25 minutes. Heat circulation: the hot air is distributed evenly into the oven by a blower fan and oven's rotary movements provide even & uniform baking at all levels of the rack. Oven has an indirect diesel fired heating system so that burnt gases do not come in contact with the baking products. The fully automatic imported burner will be fitted to the chamber and the temperature controlled by automatic temperature controller, fitted on the control panel. Door: a full stainless steel door provides with heat resistance silicone gasket that sealed the door and gains heat of the oven. Insulation: the complete oven will be covered with mineral wool insulation and mild steel or stainless steel covers to avoid heat loss. Construction: the oven body consists of mild steel. The structure of oven is stand on angle frame and the all side of oven will be covered with mild steel or stainless steel sheets. Inspection: the stainless steel doors are provided with toughened glass and interior light for the inspection during the process. Rack: the baking product is to be put in trays, which are placed in the rack, which rotates at a low rpm through a system of gearbox and motor, located at the top of the oven electrical: three phase electricity (240v / 415) required running the system. Electrical controls indicators and starters will be fitted on the control panel. Fan: the circulating fan will be well balanced to avoid vibration and will give noise free operation in high speeds. Temperature control: a digital indicating controller maintains temperature in the oven, which comes with safety thermostat and a timer along with a hooter that helps in baking cycle. Dimensions :- model apc 504, size of oven- 120" x 80" x 96", size of trolley size :- 48" x 48" x 63", h.p. Required - 5.5 h.p., size of tray - 24" x 12", bread capacity of 400 gms per trolley - 504 breads in one trolley, ovens are also avaliable in small and other capacities as per customer requirements

Bread Baking Oven

Get Price Quote

Digital Rotary Bread Oven

Get Price Quote

Bread Baking Ovens

Get Price Quote

WE ARE COUNTED AMONGST THE LEADING MANUFACTURERS, SUPPLIERS, EXPORTERS OF BREAD BAKING OVENS. Our clients can avail from us Bread Baking Ovens. Designed in accordance with the international quality norms, our Trolleys are manufactured using high grade raw material to ensure superior functionality and long life.

Indirect Type Bread Oven

Get Price Quote

Specially designed traveling type Direct or Indirect oil fired ovens along with 6" Pitch slat type conveyor, suitable for baking Bread, Buns, Rusk, Fruit Bread and Bakery Biscuits etc.

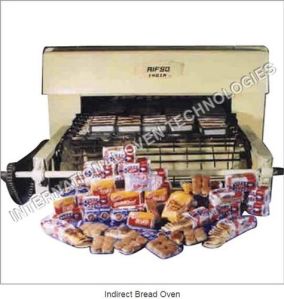

Indirect Bread Oven

Get Price Quote

bread oven

Get Price Quote

Pizza bread Ovens

Get Price Quote

Our Heating elements for Pizza bread Ovens

Bread Making Oven

Get Price Quote

Bread Baking Oven

Get Price Quote

We are engaged in offering easy to operate Bread Baking Oven for baking bread in large quantities.

bread baking

Get Price Quote

Travelling type Oven for Baking Bread, Rusk and Buns We manufacture Tunnel Oven for Bread Baking that is designed in compliance with international quality standards and perfect for biscuit baking. Our tunnel oven is separated into number of independent zones and each comprises a combustion chamber with burner, circulating fan, and turbulence fan. The ovens also have associated duct, which works for the banks of radiator tubes. Construction The oven body consists of steel steam tight tunnel with equally divided zones of the radiators. Stainless steel expansion joints are provided between these zones in order to eliminate the expansion of the oven section. The inspection doors are provided for inspection of the baking goods during the process. Firing Chambers The complete chamber will be insulated with mine wool filled from outside to conserve heat and increase efficiency. The fully automatic imported burner shall be fitted to the chamber and the temperature shall be controlled by automatic temperature controller on the control panel. Insulation The complete oven will be covered with 10" thick mineral wool insulation from top, bottom and the sides. The bottom portion of the oven at the sides will be covered with CRC sheets for the conveyor protection and to avoid heat loss. Baking System The baking in the heating chamber takes place by radiators located under and above the wire mesh band which distribute heat for uniform baking. The recirculation heating gases of these radiators can be controlled for each zone separately. The closed recirculation system is having slight vacuum so that combustion gases cannot enter into the baking chamber. The ventilating fan is for circulation of the heating gases through the recirculation system and thermostatically controlled burners provide the set temperature of the heating gases. Fans All the circulating fans are fabricated from M.S. & S.S. and will be well balanced to avoid vibration and will give noise free operation in high speeds. Capacity 2000 breads per day of 400 gms loaves Salient Features: Optimum performance Low maintenance Durable Low fuel consumption

bread oven

95,000 Per Set

Bread Baking Oven

Get Price Quote

Alif Ovens is proud to present world class Bread Baking Ovens which are made from supreme quality materials that offer anti abrasive and anti corrosive properties to it. The other basic details about our baking ovens are as follows Construction Design The Bread Baking Oven provided by us, consists of steel steam-tight tunnel equipped with similarly divided zones of radiators. It is also provided with stainless steel joints between these zones which eliminate the expansion of the oven section. Our Oven comes with inspection doors which allow direct view of the baking goods during the process. Firing Chambers Our Ovens are fitted with firing chamber, which is a completely insulated chamber with minerwoll on the outside. The firing chamber conserves heat within and thereby increases the overall efficiency of the oven. Within the chamber, we fit advanced automatic burner and imported temperature controller. Insulation The supreme Bread Baking Oven offered by us is insulated with 10� thick mineral wool from top, bottom and sides. Apart from that the bottom section of our oven is covered with CRC sheets for conveyor protection and to avoid heat loss. Baking System The advanced baking system of our oven which has radiators located under and above the wire mesh band distributes uniform heat throughout the oven chamber. It also allows for recirculation of heating gases that can be controlled separately for each zone. The recirculation system has minor vacuum which stops the combustion gases from entering the baking chamber. Our Baking system also has a ventilation fan which circulates the heating gases thought the recirculation system and thermostatically controlled burners which set the temperature of our heating gases. Fans The fans provided with our bread baking ovens are fabricated using Mild Steel and Stainless Steel that are vibration and noise free and are designed to operate efficiently at high speeds.

bread oven

Get Price Quote

bread oven, biscuit machine, Tin Printing Oven, Tunnel Oven

bread oven

Get Price Quote

bread oven, Oven - 1, Biscuit Oven, cake mixture, direct oven