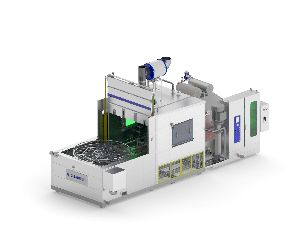

Cabinet Washing Machine

Get Price Quote

Introduction Cabinet-type cleaning machines are used for intermediate as well as final cleaning with both general and specific cleaning options. They are used for medium to large size components, ideally suitable for batch production. High level of filtration, multi-process at same place is possible. A wide range of models and process are available in this range, catering to all cleaning needs Description Cabinet type machines can be designed for general or specific cleaning, according to the need of the customer Specific component cleaning can be done according to the cleanliness level requirement. Process time is variable based of the cleaning needs Manual load/Unload or gantry loading. Operations are performed in sequence. Application CYLINDER HEAD CYLINDER BLOCKS CRANKSHAFT BALANCER SHAFT CONNECTING ROD GEARS CRANK CASE CRANK COVER GEAR BOX HOUSING CAM SHAFT GEARS AND SHAFTS AXLE HUB & HOUSING BRAKE DRUM & HUB FRONT AXLE BEAM ALLOY WHEELS MISCELLANEOUS MACHINE COMPONENTS Features SS 304 is used in water contact surfaces. Excellent operational reliability Low maintenance cost 24×7 service support Low running cost Built in safety Multi-stage filtration Cold/ Hot air blow options HMI panel with indicators MES/IOT options

Cabinet Washing Machine

300,000 Per Piece

1 Piece (MOQ)

Best Deals from Cabinet Washing Machine

cabinet type spray washing machine

Get Price Quote

FRONT LOADING & UNLOADING CABINET WASHER Cleanster Machine built cabinet type spray washing machine with rotary table and designed for large size and batch cleaning process, while retaining the cost-effectiveness of the equipment. Cabinet type cleaning machine are available in different turntable/ fixed square baskets sizes ranging from 600, 800, 1000, & 1200 mm dia. and have loading heights to meet the requirement of your process. Cabinet type cleaning machine can be customized and is available in single chamber, common point load / unload with single or multi tank with multitier filtration system suit your specific application requirements. These equipments can be designed with independent component rotation/ fixed for specific parts. Programmable control panel with human machine interface (HMI). High Pressure Spray nozzles for internal cleaning. Suitable for large parts, machined bodies and batch type production. Operation of the machine :- The parts to be cleaned are sprayed with a high flow via the spray bars, which rotate either through spray pressure or a mechanical drive. The spray bars are mounted with flat pattern nozzles, which provide efficient cleaning results. The machines are fully insulated with stainless steel panels, and therefore the wash water can be heated up to 90°C. Normal working temperature is from 60 - 75°C. Design and user friendliness:- The R 6272 A is designed totally in stainless steel both inside and out. To give the machine a more simple and neutral appearance, we have integrated a lot of components into the machine. The system has a compact construction, which makes it easier to operate. On the outside, you will find only the control panel. From this it is easy to programmed and operate the machine and make various adjustments, such as setting the speed and temperature of the separate wash tanks. At Cleanster machines our objective is to produce high quality, reliable equipment. Therefore we work carefully with all the details on our systems, but reliability is always the most important consideration. We also strive to make our machines look good. We design all our machines, so they appear functional and simple. Therefore you will find few external components on our machines. Noise of machines are minimized by integrating any noisy parts into levels the internal framework construction of machines and then using sound insulating panels. With Cleanster Machines you get a reliable and simple machine – with the functions you need. Our manufacturing philosophy is “The fewer the parts, the better the quality!” Wash day and night The R 6272A Cleaner is perfect for installation in any production lines, where machines have to run continuously for 24 hours. The machine is equipped with an efficient return flow system, which returns the cleaning solution through a filtration system to the wash tank. The wash water is continuously filtered and collects any loose debris from the components. On the pressure side of the pump system, efficient pressure filters are installed to prevent nozzles blocking, which could otherwise reduces the cleaning performance.

Cabinet Washing Machine

100,000 Per Piece

Cabinet Type Washing & Cleaning Machines

Get Price Quote

• Roto - Cab washers, Cabinet Type Component Washing Machines, Twin Chamber Washing Machines, Rotary Indexing Type Cleaning Machines are ruggedly built cabinet type spray washing machine with rotary table and designed for large size and batch cleaning process, while retaining the cost - effectiveness of the equipment • Available in different trolley / basket size and have loading heights to meet the process requirement. • Roto - Cab WR ( Water Rinse ) spray washers are multi - stage, single chamber design built for automatic washing, rinsing followed by drying operation. • Programmable control panel with human machine interface ( HMI ) • Suitable for medium to large parts, machined bodies and batch type production.

Cabinet Type Washing Machine

Get Price Quote

Cabinet Type Washing Machine, bin washing machine