Egg Laying Block Making Machine

250,000 Per piece

1 pc (MOQ)

Semi Automatic Egg Laying Solid Block Making Machine

630,000 Per Piece

1 Piece (MOQ)

Best Deals from Cable Laying Machine

Block Laying Machine

Get Price Quote

1 Piece (MOQ)

PLC Automatic Rusk Laying Machine

Get Price Quote

1 Piece (MOQ)

Details Castors with lock machanism Adjustable bread slicing platform height Speed invertor for models with conveyors Crumb collecting tray for easy cleaning Suitable to slice all kind af breads and rusk Compact and heavy duty body Simple and fast changing blades Slice thickness from 8 to I8 mm (Other on request) Easy and safe to clean thanks to easy accessible Crunb tray box on front side Economically and well prices Very slient and even slicing Dimensions 4165mm/ 163.97"/ 13.7' (L) 1325mm/ 52.1" / 4.4'(W) 1150mm / 45.3" / 3.81H)

Semi Automatic Egg Laying Block Making Machine (RBM-04)

Get Price Quote

Having accumulated knowledge and experience over the years, we are able to bring forth the supreme quality in the form of Semi Automatic Egg Laying Block Making Machine (RBM-04). We present incredible quality to our customers. We make use of top-quality raw material to ensure low maintenance, durability and elevated service life. It finds its application in several industries. Get in touch to avail highly competitive prices. Details : Egg-Lying Type Concrete Block Making Machine with Mould, Vibrator- 2HP-2800RPM OR 3HP Petrol/Diesel Engine, Block Capacity-1000/Shift. Model No. - RBM4

Kerb Laying Machine

600,000 - 755,000 Per piece

1 piece (MOQ)

EGG Laying Solid Block Making Machine

540,000 Per Piece

1 Piece(s) (MOQ)

Core Laying Machine

Get Price Quote

Features : The machine is suitable for laying 3-7 core PVC/XLPE Insulated round cables with back twist and sector cables without back twist Motorized sector correction model available Centralized lubricating system for gears & bearings Machine drive by mechanical synchronization or by individual AC motor, drive for machine components Heavy, robust fabricated cradles Hardened and ground gears Haul off through a twin grip cater puller or heavy duty taper machined capstan with fleeting ring

Kerb Laying Machine

400,000 Per piece

Astech Kerb Stone Laying Machine

Get Price Quote

1 Piece (MOQ)

Suncross Rusk Laying Machine

600,000 Per Piece

1 Piece (MOQ)

Underground Cable Laying Machine

Get Price Quote

1 Set Unit (MOQ)

Egg Laying Block Making Machines

Get Price Quote

We are offering egg laying block making machines. ibm 1060 model double vibrator. production capacity 40- 50 strokes / hour 400 x 100 x 200 mm10 block / stroke – 3200 – 4000/ shift 400 x 150 x 200 mm 6 block / stroke –1900 – 2400/ shift 400 x 200 x 200 mm 5 block / stroke – 1600 -2000/ shift

Core Laying Machine

Get Price Quote

The machine is used for cabling the multi core (3, 3 & ½, 4), pvc cables, xlpe cables in round or sector shaped for lt and ht cables. Ariel bunched cables can be laid in (1+4) bobbin configuration. Main features • machine may strand the round cables with back twist and sector cables without back twist. • line drive by a.c. Motors with electronic or mechanical synchronization between line components. • facilitated with motorized sector correction • with or without back twist arrangement (sun and planetary arrangement) • main shaft is supported with roller bearing for easy maintenance • special gear boxes for main drive • heavy duty pneumatic drum brake for main cage • filler bobbin provision for 6 to 9 bobbins • mmi and plc equipped (optional) • heavy duty haul off caterpillar unit • inline tangential or concentric taping heads model rotor speed (rpm) driven motors (hp) dskcl1+31250 50 40 dskcl1+31400 45 50 dskcl1+31600 30 65 dskcl1+31800 20 80 dskcl1+41250 50 40

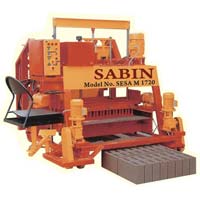

High Capacity Hydraulic Type Egg Laying Block Making Machine (SESA M 1720)

Get Price Quote

High Quality Hydraulic Type Egg Laying Block Making Machine with Storage Box (hopper) and Auto Feeder Model No. SESA M 1720 Salient Features : Quick Production High quality concrete blocks Very Less Maintenance Electrical circuit is designed to avoid manual error. Very good service Any mould as per customers specification This is a Mobile Type Concrete Block Making Machine and hence produce blocks on concrete floor. Any type of concrete blocks can be made by fixing different type of mould and ram into the machine. The Machine is same as our Model SHM 105 M 860 Special Type but this machine is having a storage box (Hopper) alongwith an auto feeder and do not have to feed the material to the machine manually but only feed the mixer to the hopper (storage box) and from it, it will automatically feeded to the moulds as per the required quantity. The Machine size also little bigger than the existing machine since when adding the storage and auto feeder, the size of the machine become more length and wider to adjust the hopper and the auto feeder as accordingly the weight of the machine also more than 200 kgs extra. This machine is just more convenient and easy to operate and also mobile type. The storage capacity of the hopper is about one bag mixer quantity. Size of Moulds - 400 x 200 x 100 (4") 16 Nos/cycle 800/hr 6400 nos/day of 8 hrs. 400 x 200 x 150 (6") 10 Nos/cycle 500/hr 4000 nos/day of 8 hrs. 400 x 200 x 200 (8") 08 Nos/cycle 400/hr 3200 nos/day of 8 hrs.

plastic mulch laying machine

60,000 Per Piece

36 Armouring Cum Core Laying Machine

Get Price Quote

Kerb Laying Machine

Get Price Quote

Kerb Laying Engine

Get Price Quote

1 Piece (MOQ)

Mechanized Sleeper Laying Machine SLM

Get Price Quote

Hme sleeper laying machine slm. part of mechanised railway track construction. This machine lifts 20 sleeper simultaneously using its hydraulic lifting beam then travels to the site and lays down the sleepers 20 numbers simultaneously equally spaced and parallel to one another as per railway standards