Die Casting Service

Get Price Quote

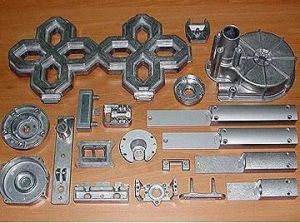

Our die casting service delivers precision-engineered components with exceptional quality and durability. Utilizing advanced technology and state-of-the-art equipment, we produce intricate metal parts for various industries, ensuring optimal performance and reliability. Our team of skilled professionals is dedicated to meeting your exact specifications, providing cost-effective solutions, and maintaining the highest standards of quality control. Whether for automotive, aerospace, or industrial applications, our die casting service guarantees timely delivery and unparalleled customer satisfaction. Partner with us for your die casting needs.

Aluminium Casting Services

Get Price Quote

If you are looking of aluminium casting services service in Mumbai (Maharashtra), then you must try the services offered by Shubh Castings. We have an impressive history of casting Aluminium components of different specifications and dimensions. A number of clients appreciate our aluminium casting service as it is effective, precise, timely, and affordable. When you obtain our zinc die casting service, you get the benefits like uniform hardness and grain flow, high tensile strength, excellent surface finish, fantastic load-bearing capacity, and many more.

Looking for Casting Service Providers

aluminium casting service

280 Per Kilogram

10 Piece (MOQ)

For many years, Indian Casting has focused on casting aluminium. With cutting-edge part designs and dependable quality, our aluminium casting service has helped engineers, product designers, and architects bring their concepts to reality. Your castings will be made with the highest level of quality and efficiency possible because of our significant industry knowledge, cutting-edge machinery, skilled manufacturing and quality engineers, and well-trained production employees. Indian Casting gives you comprehensive and thorough assembly and testing of all cast parts and products as part of its entire range of aluminium casting services. We offer a wide range of services to meet the demands of our clients, whether they are interested in specialised aspects like aluminium casting or just want to prototype a new part.

Pedestals For Pressure Die Casting Machine Fabrication Services

Get Price Quote

If seeking for Pedestals For Pressure Die Casting Machine Fabrication services, contact us! We are a high-flying Service provider, actively involved in providing services for Die Casting Machine Fabrication. We are supported by a group of personnel who render these services as per the client’s preferences and budgetary limitations. Furthermore, our fabricated machines are highly efficient and have long service life. Interested clients can approach us anytime for further inquiries!

die casting services

Get Price Quote

Specializing in Die Casting Services, we excel in manufacturing premium Agricultural Machinery Parts, Textile Machinery Parts, Two-Wheeler Casting Parts, Washing Machine Parts, and Grinder Machine Parts. Our cutting-edge technology and expertise ensure the production of intricate, high-precision components for diverse industries. With a focus on quality and efficiency, we meet the specific requirements of each sector, delivering reliable and durable solutions. Choose our Die Casting Services for precision-crafted parts that contribute to the optimal performance of agricultural, textile, automotive, and household machinery.

CNC Machined Casting Service

Get Price Quote

CNC machined casting services involve the precision machining of cast metal parts using computer numerical control (CNC) technology. This process starts with casting raw metal into desired shapes, followed by CNC machining to achieve precise dimensions, tight tolerances, and smooth finishes. Widely utilized in industries such as automotive, aerospace, and heavy machinery, this service combines the cost-effectiveness of casting with the accuracy of CNC machining. It is ideal for producing complex geometries and high-performance components, ensuring consistency and quality. CNC machined casting services enhance production efficiency, reduce material waste, and provide high-quality, ready-to-use parts for various applications.

Die Cast Machine Refurbishing Services

Get Price Quote

Refurbishing Services: High-tech tools Exceptional performance Experienced team force Consistent function of Refurbished items Cost effective Provide services for: Repairs Proper maintenance Addition and replacement of damaged parts

Zinc Die Casting Services

Get Price Quote

Optimize your product design with our zinc die casting services. Zinc's unique properties offer excellent castability, durability, and cost-effectiveness. Our precision tooling and advanced casting processes deliver high-quality parts with intricate details. Ideal for automotive, electronics, and hardware applications. Benefit from rapid production, reduced material waste, and improved part performance. Let us transform your designs into durable zinc components.

die casting services

Get Price Quote

We are having die-casting shop with machines ranging from 75 to 800 tonnes capable of producing components from 0.5 grams to 8.5 kg. Our fully automated closed loop die casting cells maintain history of process parameters for every shot. It achieves repeatability and quality in every shot by adjusting itself automatically to reach the set parameters.We have defined special process parameters and aids to achieve wall thicknesses as thin as 1.2 mm and as thick as 10 mm without problems. We utilize Control Plans + Process Parameter Sheets and die maintenance plan, spares for every item to eliminate production errors, improve surface finish and integrity of castings, to reduce wear and tear of die to enable timely dispatches.Proof machining is carried out on all machined areas during casting cycle. Traceability is maintained up to 3 years for on line inspection reports, material composition and our suppliers heat no.

investment casting services

Get Price Quote

Perfect Engineers offers top-quantity investment casting services. Our in-house services comprise advanced machining, ceramic mold making, heat treatment, and casting for numerous materials and project results. We give dimensional precision and precise components depending on the precise requirements of your project. Our supreme industry experience and access to advanced tools give project managers the ability to create high quantity metal parts and elements within the size and range of timelines, budgets, and quality standards. If machining is necessary, our one-stop-shop can deliver outside finishing for intricate geometry parts. If you are interested in our services, contact us now for more information.

Engine Casting Crack Repair Service

Get Price Quote

The crack repair and repair of damaged cast iron casting and aluminum cast parts are repaired by metal locking and metal stitching process. RA Power Solutions have team of technicians having valid CDC and can fly any part of the world to execute repair of cracks or repair of damage casting by metal locking and metal stitching process.

Zinc Die Casting Job Work

Get Price Quote

Zinc die casting job work involves the process of manufacturing precision metal parts by injecting molten zinc into a mold under high pressure. This technique is ideal for producing durable, intricate, and high-quality components used in various industries like automotive, electronics, and hardware. Zinc die casting offers excellent dimensional accuracy, corrosion resistance, and cost-efficiency. Professional job work services ensure that the casting is tailored to the client’s specifications, providing a reliable solution for mass production and custom metal parts.

C.I Casting

Get Price Quote

C.I Casting

Casting Impregnation Services

Get Price Quote

P.D. Enterprises takes pleasure in providing casting impregnation services that set the standard for the industry in ensuring the dependability and integrity of your castings. Any porosity or microvoids in metal castings are successfully sealed by our unique impregnation technique, preventing leaks and improving performance. We can efficiently and precisely impregnate a variety of castings, including those used in automotive, aerospace, industrial, and other industries, thanks to our highly skilled workforce and cutting-edge technology. To get the greatest results, we meticulously examine each casting to choose the appropriate impregnation method. With years of industry experience, we promise excellent service, rapid response times, and reasonable prices. Experience the peace of mind that comes with relying on P.D. Enterprises for all your Casting Impregnation requirements.

Casting Services

Get Price Quote

Process Overview – It is a process of making parts by pouring molten metal into a die and then cooling it to room temperature so that it takes the shape of the die. It is a less expensive method of manufacturing compared to machining an entire piece of solid metal. Casting is broadly categorized into three main types : Sand Casting - This process is characterized by using sand as the mold material. The mold cavities and gate system are created by compacting the sand around patterns which can be made of wood, metal, plastics, silicon rubber etc. and manufactured by casting, machining or 3D printing based on the requirement of the final casted part. Investment Casting - The mold is formed by dipping or spraying ceramic slurry around a wax pattern or wax tree. Prior to pouring, the wax is burnt off by keeping it in a steam-dewax autoclave or flash fire oven. On completion, the same is cooled to room temperature and the shell is removed usually by mechanical tools. The parts are then machined, ground and polished to achieve the required dimensions and characteristics. The general process flow for Investment Casting include : Wax Pattern Injection Wax Tree Assembly Shell Building Dewax/Burnout Metal Pouring Shell Knock-off Cut-off Individual Casting Die Casting - The molten metal is forced into a mold cavity made up of metal, under the application of high pressure or under gravity. In Gravity Die casting the molten metal gets drawn into the mold under the action of its own gravity. Pressure Die casting is further classified into Low, Medium, and High-pressure basis the force exerted by the plunger to push the molten metal inside the mold cavity. Pressure Die castings have a tight tolerance, better surface finish, high volume production and very critical parts compared to its contemporary casting processes. A die cast part has to go through the below process flow : Melting Casting Fettling Shot Blasting Machining Capabilities Integrated sequential manufacturing process under one roof i.e., Simulation -> Tool designing and manufacturing -> Prototype -> Manufacturing Prototype to high volume production of up to million parts per year Monthly production capacity of up to 100MT/month Capability to cast parts up to 10 Tonnes Manufacturing of wide variety of grades such as Carbon Steel, Stainless Steel, Duplex, Super Duplex, Aluminum and Brass Alloys etc. Different follow up Heat Treatment process such as Normalizing, Annealing, Hardening, Tempering etc. based on the requirement of mechanical and chemical properties Post finishing and surface treatment process such as Anodizing, Painting, Plating, Powder coating etc. Flexibility of end-to-end machining of small to large sized parts Achieve as cast tolerance of up to ± 0.2mm and machined tolerance of up to ± 0.025mm As cast surface finish as low as 1.6 Ra micron Use of advanced CAD-CAM software for simulation and tool/die making One of the few in INDIA to perform Hot Isostatic Process (HIPPING) Use of “Low Therm Fettling Technique” to control microstructure In-house lab tests carried out for raw material verification at production site, certified to NABL standards Complete NDT testing of parts for defect analysis as per international standards Manufacturing facility certified to ISO 9001:2015 and IATF 16949 Quality Management System Application and Benefits Sand castings have a wide range of application in almost all engineering industry due to its versatility of material selection, simplistic process, and low cost. Few common applications in the Transport and Automotive industry include cylinder heads, valves, engine blocks, engine manifolds, gears, brackets etc. Sand castings are primarily chosen for manufacturing of prototype parts due to its low investment cost and higher degree of flexibility Investment casting is widely used for : Engineering components such as turbines and rotor blades in motors and generators Valve parts such as casings, pistons etc. Wide variety of Orthopedic implants Commercial and Consumer products Many die cast parts are made in the Aerospace and Automotive industry from high strength aluminum and light weight magnesium Few well known benefits of Die casting include : Manufacturing of critical parts with cross section as thin as 1.5mm Manufacturing of parts with complex geometry and diverse applications Parts have better strength and integrity High volume production Fully automated process with better process control Better repeatability gives consistent good quality parts Parts have high dimensional accuracy, close tolerance, surface finish and longer service life Post-machining can be eliminated Molds have a very long operational life Very economical for high volume production

Aluminium Casting Services

Get Price Quote

King Metals And Alloys Madras Ltd is a recognized service provider of a wide range of aluminium die casting services in India. We are a Tamil Nadu (India) based firm dedicated to offer high-precision prototyping as per the demands placed by our customers to provide top quality aluminium die cast parts. Our premier casting solutions are efficient to help our clients in getting desired finished products according to the requirements placed by them for engineering and custom specifications. Our team of engineers is a hub of experts who offer efficient operational casting solutions by testing every design to execute a desired one demanded by our clients.

Shell Moulding Casting Service

Get Price Quote

Our Shell Moulding Casting Service offers a sophisticated and precise method for producing intricate metal parts with exceptional dimensional accuracy and surface finish. Utilizing advanced shell moulding techniques, we ensure high-quality results for a variety of industries including automotive, aerospace, electronics, and more. Our process begins with the creation of a shell mould composed of a fine sand mixture and resin, providing excellent dimensional stability and surface detail. This mould is then filled with molten metal under controlled conditions, ensuring uniformity and consistency throughout the casting. With our expertise and state-of-the-art facilities, we can accommodate a wide range of part sizes and complexities, from small intricate components to large industrial parts. Our commitment to quality and efficiency ensures timely delivery of your components, meeting your exact specifications and requirements.

Casting Forging And Pattern Inspection Service

Get Price Quote

Immerse yourself in superior audio with our Home Theater Acoustic Panel Installation Services. Our expert technicians strategically place acoustic panels to optimize sound quality, reducing echoes and enhancing clarity. Customized to your room's acoustics, these panels transform your space into a cinematic haven. Experience audio like never before, with every note and dialogue crystal clear. Elevate your home theater experience with our precise and professional Acoustic Panel Installation Services. Transform your space into a sonic masterpiece.

Bowl Casting Service

60,000 - 70,000 Per Piece

1 Piece (MOQ)

Tetrapod Casting and Placing Service

Get Price Quote

We are experienced in casting and placing works of tetrapod ranging from 1Ton - 25 Ton. Tetrapod works is done for breaking wave pressure of sea and protecting the Marine Infrastructure. Our Tetrapod Casting and Placing service specializes in the production and installation of tetrapods for coastal protection projects. These durable concrete structures are designed to absorb and dissipate wave energy, preventing shoreline erosion and protecting infrastructure. We offer custom casting solutions tailored to project specifications, ensuring optimal size and strength. Our experienced team efficiently places tetrapods using advanced equipment, providing cost-effective, long-lasting protection for ports, breakwaters, and coastal environments. Trust us for reliable, high-quality tetrapod solutions.