Cenosphere Powder

Get Price Quote

cenosphere

25,000 - 40,000 Per Metric Ton

5 Metric Ton (MOQ)

Best Deals from Cenosphere

cenosphere

Get Price Quote

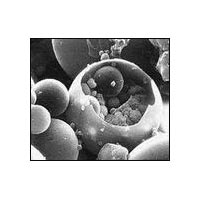

Cenospheres are light weight, inert, hollow speres of Silica and Alumina filled with gas which naturally occurs in the combustion of coal. The properties are same as manufactured sphered products. Thus it is also called as Glass beads.

Cenosphere Powder

Get Price Quote

100 Kilogram (MOQ)

A cenosphere or kenosphere is a lightweight, inert, hollow sphere made largely of silica and alumina and filled with air or inert gas, typically produced as a coal combustion byproduct at thermal power plants. We cenosphere manufacturers & suppliers from India, China, UAE.

cenosphere

Get Price Quote

We Export & Supply Well-processed Cenosphere in Bulk Quantity.

Cenosphere raw

Get Price Quote

21 Metric Ton (MOQ)

We are the Quality supplier of raw cenosphere at most economial prices in Central india. Due to the high quality of our raw cenosphere it is easily to process and it is almost free from sinkers. Hence it is highly demanded in cenosphere processing plants. It is a lightweight, inert, hollow sphere made largely of silica and alumina and filled with air or inert gas. The color of cenospheres varies from gray to almost white and their density is about 0.4–0.8 gcm3 (0.014–0.029 lbcu in), which gives them a great buoyancy. Cenospheres are hard and rigid, light, waterproof, innoxious and insulative. This makes them highly useful in a variety of products.

cenosphere

Get Price Quote

10 Metric Ton (MOQ)

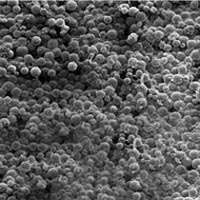

A cenosphere is a lightweight, inert, hollow sphere made largely of silica and alumina and filled with air or inert gas.typically produced as a byproduct of coal combustion at thermal power plants. Cenospheres are unique free flowing powders composed of hard shelled, hollow, minute spheres. A small proportion of the pulverised fuel ash (pfa) produced from the combustion of coal in power stations is formed as cenospheres. Cenospheres are made up of silica, iron and alumina. Cenospheres have a size range from 1 to 500 microns with an average compressive strength of 3000+ psi. Colors range from white to dark gray. They are also referred to as microspheres, hollow spheres, hollow ceramic microspheres, microballoons, or glass beads.

cenosphere

Get Price Quote

The cenosphere that we are offering are lightweight, hollow, and spherical in shape. These hollow spheres are filled with air and gas to enhance their flowability. These cenospheres are available in a packaging size of 25 kgs to 50 kgs.

cenosphere

60,000 Per Metric Ton

200 Metric Ton (MOQ)

We are one of the leading exporter of CENOSPHERE exporting in container loads to Middle east & other countries. Packing will bein 600 kg. jumbo bags, 40 bags in container net wt. 24 tons in 40 feet high cube container.

cenosphere

80 - 100 Per Kilograms

1 MT (MOQ)

cenosphere

Get Price Quote

20 Metric Ton (MOQ)

Cenospheres are hollow ceramic microspheres with special characteristics that enable them to be used in a wide numbers of applications. Cenospheres are light weight, inert hollow sphere of silica alumina filled with gas which naturally occurs in the combustion of coal. The sphere has nature’s most efficient shape with the lowest surface area compares to volume. It is these shapers which enables cenospheres in such a wide range of users other than simply being used as lightweight fillers.Cenospheres are having unique combination of low specific gravity controlled size and high compression, good thermal and accountable insulating property. Cenospheres are hard and rigid, light, waterproof, innoxious and insulative. This makes them highly useful in a variety of products, notably fillers.Cenospheres have a high melting point of 1200-1800 C. They are therefore excellent for use in high temperature insulating refractory’s and fire resistance coating and panels. We supply Cenospheres based on specific gravity, size distribution, colour etc. engineered to specific customer’s demands packed in Lined 500 kg Jumbo bags or Laminated 20 kg craft paper bags. Applications of Cenosphere : Oil well Cements Foam Carpet Backing Light Cement Boards Low density Polyethylene & Polypropylene Specialty Cement & Mortars Roofing Materials Acoustic Panels Special Industrial Paints & Coatings High Grade Refractories Fire Bricks, Tiles Advantages of Cenospheres : Reduced Raw Material’s Cost Reduced Resin Demand Reduced End Product Weight Improved Flow Ability Improved Insulation Values Resistant to Resin Absorption

cenosphere

Get Price Quote

Khetan udyog is a manufacturer and global supplier of processed cenosphere. We manufacturer clean and graded cenosphere which have high compressive strength. Their light gray color consistency will always give you the result you expect. Our cenosphere provide all the benefits you would expect from a microsphere and can improve the properties and performance of many formulated products.

Cenospheres

Get Price Quote

Cenospheres are unique free flowing powders composed of hard shelled, hollow, minute spheres. A small proportion of the pulverised fuel ash (PFA) produced from the combustion of coal in power stations is formed as Cenospheres. Cenospheres are madeup of silica, iron and alumina. Cenospheres have a size range from 1 to 500 micronswith an average compressive strength of 3000+ psi. Colors range from white to darkgray. They are also referred to as microspheres, hollow spheres, hollow ceramicmicrospheres, microballoons, or glass beads. The main characteristics are: Hollow spheres with spherical morphology Particle sizes ranging from sub-micron to millimeters in size. Ultra low density Low thermal conductivity High particle strength Resistant to acids Low water absorption Hollow spheres have been used for more than 20 years to improve the properties of avariety of finished consumer products. They were first introduced as an extender for plastic compounds, as they are compatible with plastisols, thermoplastics, latex, polyesters, epoxies, phenolic resins, and urethanes. Synthetic foams made with cenospheres have demonstrated superior mechanical properties when compared to those manufactured with fabricated microspheres. The compatibility of cenospheres with specialty cements and other building materials such as coatings and composites was also quickly identified. Since that time cenospheres have been used in a wide variety of other products, including sports equipment, insulations, automobile bodies, marine craft bodies, paints, and fire and heat protection devices.

Processed Cenosphere

Get Price Quote

We are one of the leading Manufacturers, Suppliers and Exporters of Processed Cenosphere, operating from Raipur, Chhattisgarh. Processed Cenosphere is a hollow ceramic microsphere found in fly ash, a natural by-product of coal combustion during the generation of electric power. Processed Cenosphere is used as filler or functional extender in the manufacturing of plastics, paints, resins, light weight aggregates for cement, ceramics and other construction products. Because Processed Cenosphere, often replaces mined materials, it can significantly minimize production costs. Simultaneously, Processed Cenosphere can benefit finished product properties by increasing durability and better sound proofing. Too, as material recycled from fly ash. Processed Cenosphere has a size range from 45 to 425 microns with an average compressive strength of 3000+ psi. Colors range from white to dark gray. Processed Cenosphere is also referred to as microsphere, hollow sphere, hollow ceramic microsphere, micro balloon, or glass bead. The spherical shape of Processed Cenosphere improves flow ability in most applications and provides a more even distribution of the filler material. The natural properties of Processed Cenosphere, make it possible to use it either in dry or wet slurry form. Processed Cenosphere is easy to handle and provides a low surface area-to-volume ratio. Due to its inert properties, Processed Cenosphere is not affected by solvents, water, acids, or alkalis. Cenospheres are 75% lighter than other minerals currently used as a filler or extender. Utility : Reduced raw materials cost Improved flow ability Reduced resin demand Improved insulation values Reduced end product weight Resistant to resin absorption

cenosphere

Get Price Quote

The spherical shape of cenospheres improves flowability in most applications and provides a more even distribution of the filler material. The natural properties of cenospheres make it possible to use them either in dry or wet slurry form. Cenospheres are easy to handle and provide a low surface area-to-volume ratio. Due to their inert properties, they are not affected by solvents, water, acids, or alkalis. cenospheres are 75% lighter than other minerals currently used as a filler or extender and are 30 percent lighter than most resins

Cenosphere Powder

11 - 12 Per Kilo

200 Metric Ton (MOQ)

Cenosphere Powder

55 - 60 Per kg

100 Ton (MOQ)

Cenosphere used in paint and ceramic

cenosphere

55,000 Per Metric Ton

5 Metric Ton (MOQ)

cenosphere

Get Price Quote

Cenosphere is a lightweight, inert, hollow sphere that is comprised of silica and alumina and filled with air or gases. Cenosphere is the by-product of the burning process at coal-fired power plants. Cenosphere provides several benefits like reduced raw materials, flowability, improved insulation values, resistant to resin, reduced end product weight, etc. Advantages : Manufacturing Benefits : The spherical shape of Cenospheres improves flowability in most applications and provides a more even distribution of the filler material. The natural properties of Cenospheres make it possible to use them either in dry or wet slurry form. Cenospheres are easy to handle and provide a low surface area-to-volume ratio. Due to their inert properties, they are not affected by solvents, water, acids, or alkalis. Cenospheres are 75% lighter than other minerals currently used as a filler or extender and are 30 percent lighter than most resins. Product Improvement : Cenospheres can improve manufacturers' end products by improving strength, durability, and by reducing weight. Cenospheres also provide added buoyancy, better insulative properties, and reduced shrinkage and warpage values. Their spherical shape may improve product stability and increase resistance to impact. Used in the production of insulating materials, Cenospheres better control both sound values and thermal conductivity. Many other benefits or advantages may be realized depending on the application. Improved Marketing Strategies : Improvements in the durability and strength of manufacturers' end products and a reduction in product weight enhance marketing strategies. A largely unaddressed advantage for product manufacturers is an environmentally responsible end-product. Manufacturers can use Cenospheres to produce an improved finished product without adding to the Earth's overburdened landfills. The chemically inert properties of Cenospheres make them 100 percent recyclable. With society's heightened interest in environmental concerns, the recyclable properties of Cenospheres can and should be used in marketing the manufacturers' end product. Applications : Automobiles : Fabrication of composite polymeric putties Ceramics : Refractories, Tiles, Fire bricks\Construction: Cenospheres is widely used in the construction industry. From roofing materials to stuccos and grouts, new applications and products continue to be developed. The quantity of Cenospheres used within the construction industry continues to grow today as more and more companies realize the advantages Cenospheres bring to their products. Oil Fields: Cenospheres have been used in oilfield cementing for quite some time. During a cementing job, Cenospheres act to decrease the slurry density without increasing the water content. This in turn provides better compressive strength to the cement. Plastics : Cenospheres are an excellent lightweight filler for plastics and continue to grow in popularity and use. Not only do they reduce the cost of the composite but Cenospheres often impart performance improvements that might otherwise not have been achieved. It is used in all types of Moulding, Nylon, Low Density Polyethylene and Polypropylene

cenosphere

Get Price Quote