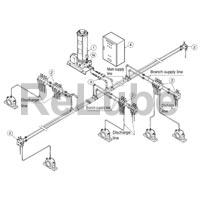

Dual Line Lubrication System

Get Price Quote

Dual Line Lubrication System that we offer is well tested and therefore, is the perfect option on which buyers can easily rely. We are reckoned as one of the reputed Manufacturers and Suppliers of Dual Line Lubrication System. Manufactured under the strict vigilance of experts, our Lubrication System is known for its longer functional life. Tested using the latest techniques, our Lubrication System is free from all kinds of defects. Principle of operation : Two parallel lines run from pump to control valves and from control valves to metering devices and then to bearing points. End of line pressure switch gives signal to change over the line and thus continuous operation is ensured. Construction & operationA single outlet pump, 4/2 way direction control valve, metering devices, end of line pressure switches etc. are important parts of the system. In this system, lubricant is supplied from central pump to control valve, which further supplies it to the main lines and ultimately to bearings. When pump os started, one of the main line gets charged, it delivers required quantity of lubricant to bearings and at that time other main line acts as a relief line. When end if line pressure switch sends signal to changeover the line (i.e. half of the total number of lubrication points are covered.) After getting signal from end of line pressure switch, the changeover valve operates and the other main line gets charged and remaining half number of lubrication points gets lubricated. This ensures one complete cycle. Advantages of this system is that the pump used is high volume, high pressure type and number of bearings can be centralised is large (up to 1000 points). Applications Sugarcane Crushing Mills, Steel Rolling Mills, Metal Processing Machines, Power Plant Conveyers and Grate Coolers.

Lube Modules

Get Price Quote

Best Deals from Centralised Lubrication Systems

lube oil extraction system

Get Price Quote

Re-refining is a profitable opportunity since lube oil can be re-refined as many times as you like, therefore becoming a very attractive business opportunity while safeguarding the environment.

Dual Line Grease Lubricant System

Get Price Quote

We are the leading manufacture and supplier of wide assortment of Greasing Distributors which are manufactured at par with the industry laid standards. Entire range of these products is manufactured under the strict eye of our quality controllers who make sure that the products have no defect. The Greasing Distributors are extensively used for distributing the oil or grease in even or metered quantity, to all the lubrication points in a plant or a machine. We offer these products at market leading prices and deliver them on time.

Dual Line Lubrication System

Get Price Quote

The Dual Line Lubrication System has convinient installation and high productivity rate. All thanks to our smart inventory management owing to which safe and quick deliveries are furnished by us. For ensuring safety of the products during handling, warehousing and transportation, we make use of quality packing material. Moreover, the task of packaging is undertaken by the experts.

centralised lubrication systems

5,500 Per Piece

oil lubrication systems

3,000 - 50,000 Per Piece

01 Piece (MOQ)

oil lubrication system

Get Price Quote

Oil Lubrication System We offer centralized Oil Lubrication Systems which ensure adequate supply of the oil at specific pressure and temperature for the desired applications to keep the rotating parts well lubricated. Our units are made as packaged units ready for piping. Our range of centralized Oil Lubrication Systems are high in demand in various industrial units. Features: It is totally re-circulating type. Oil is sucked from the reservoirIt is ejected on gears and bearingsHot oil returns back to the tankWhere oil is cooled before pushing towards the bearing and gear boxSystem is not of high pressureThere are terms like filters, coolers as optionalSimilar system is also provided for boiler and centrifuge

lube oil system

Get Price Quote

To cater this need CEE DEE VACUUM provides a solution with supplying oil storage tanks. There are different types of these tanks. The tank and capacity can be designed to suit the application and are available in the following categories: Mobile (Capacity range 1KL - 35KL), With Insulation, Without Insulation.

oil lubrication system

Get Price Quote

Oil Lubrication Systems are complete, self-contained systems designed for smaller applications such as stamping presses, punch presses and crushers. Each unit is locally assembled and tested for flow, pressure, sound levels and proper operation. Standard units usually include: electric motor and pump, oil filters, level indicators, flow meters, pressure gauge and steel oil reservoir.

lube oil system

Get Price Quote

We are reliable manufacturer and exporter of Lube Oil Systems in India. We offers Lube Oil Systems for a wide range of applications from onshore industrial systems serving steam turbine generators to all stainless steel and duplex systems serving gas compressors /seawater injection pumps operating in the harsh conditions found offshore. As a renowned manufacturer of Lube Oil Systems in Gujarat, we design our systems in accordance with customers own requirements. We supplies Lube Oil Systems that include pumps, heat exchangers, filters, controls and instrumentation. Built under controlled conditions in a fabrication facility, systems are mounted on structural steel bases designed for easy and safe transport to the end user’s facility. We supply Lube Oil Systems that are proved the best in the industry acclaimed by customers worldwide. Reach us today, We are an eminent Lube Oil Systems Supplier in India.

turbine lube oil purification system

135,000 - 199,000 Per pc

1 pcs (MOQ)

turbine lube oil purification system, Alfa Laval Oil Purifier

Industrial Lubrication System

Get Price Quote

We offer Industrial Lubrication System. Automatic Micro-Mist Oil Lubrication System (Micro-Fog) Principle of working: The lubricant is atomized to 4-6 micron sizes. They form a mist and are coalesced at the point of application to lubricate the two surfaces under friction. Advantages: * Can be easily installed on the existing machine. * Increases machine life * Simple to connect and operate. * With Oil control suitable lubricant is used, thus avoids lubricant wastage. * No extra cost on return pipe lines, pump and filtering systems as there is no recirculation. * As No wastage of oil nor any generation of fumes due to heating hence makes it Environmentally friendly. Applications: * Petroleum and chemical Industry * Refinery * Gear Boxes * Rolling Mills *Textile Mills * Machine Tools * High speed spindle bearings *Food processing Industry * Sugar Mills etc Models: Economic, Semi-Auto and Automatic. Specailly designed for Rolling Mills, Sugar Mill Roller Bearings, Conveyors, Food Industry, Textile Mills etc.

CGL- Centralised Grease Lubrication systems

250,000 Per Set

1 Set(s) (MOQ)

By utilizing skills of our dexterous workforce, we are offering a comprehensive assortment of Dual Line Lubrication System. We manufacture this system by employing optimum quality steel, metal and modern technology. Our offered system has been appraised for its smooth fabrication, high functionality, proper installation, reduced maintenance and long service life. Furthermore, we can offer this system to our esteemed clients at affordable rates. Features: Non corrosive Precise design Easy installation Description: Lubrication systems engineered with the Dual Line system are generally used on large scale machinery and in harsh operating conditions to lubricate multiple points on large machines. The system can grow to a very complex one with a length that often can exceed 60 meters. The large section of pump packages together with many custom design options allows any lubrication system to be developed reliably and cost-effectively.

centralised lubrication systems

Get Price Quote

This control unit is designed for use on All pumps used on vehicles and construction machines. Run time between 01-07 min. and Pause time between 30-210 min. For more flexible options of timing, minimum batch qty. of 50 no. Optional external alarm. Rated output: 10 amp relay Protection: Fuse Protection 3 amp quick action fuse. Can also be mounted inside a panel. The control unit resumes at the correct point after electrical supply interruption. High speed mode for testing provided.

Dual Line Lubrication System

Get Price Quote

Dual Line Lubrication System that we offer is manufactured by our experienced professionals using premium components with the aid of advanced technology. It is known for its longer functional life and smooth functionality. We are one of the reputed Manufacturers, Exporters and Suppliers of Dual Line Lubrication System from Haryana, India. We are efficient enough to process retail as well as bulk orders for Dual Line Lubrication System even at short notice period. Features : Low power consumption Trouble free performance Corrosion free coating Easy to install Specifications : Dual lubrication system, a parallel type lubrication system, has two main lines running across the length and breadth of the equipment. Metering devices called "dose feeders" are installed close to the lubrication points. High pressure grease pump feeds the entire system and has options of manual, motorized and pneumatic drive to choose from. Pumping Station : With Safety Valve, Pressure Gauge and Lubricant filter Pumps all type of oils and grease (upto NLGI 2) Motorised Pump : No. of outlets - One Max. Op. Pressure - 400 Bar Reservoir Capacity - 50 / 100 Litres Lubricant output - 9litres/hr and 14 Litres/hour Drive - Electrical Motor with gear box Power supply - 415V, 50Hz, 3 phase, 0.75KW Pneumatic Pump : Mounted on 180 kg grease barrel Manual Pump : Max. Op. Pressure - 400 Bar Reservoir Capacity - 2.5 / 4 Litres Change Over Value : Hydraulically operated with indicator pin with proximity switch Option of motorised valve and solenoid operated valve available Dose Feeders : Have adjustable output and indicator pin for monitoring Options available in dose outputs and in construction type - modular and mono-block Inlet connection - 3/8"BSP (Female) Outlet connection - 1/4"BSP (Female) Control Panel For controlling the operations of centralised system having following features : Lubrication cycle count Off-time setting Reservoirs low level indication Fault Annunciation by audio/visual indication Motor Overload / short circuit Protection

Air Plus Oil Lubrication Systems

Get Price Quote

Lubcon Engineers Air Plus Oil Mix Lubrication System are designed for applications where minute amount of metered lubricant is required to be applied on a surface. Lubcon Engineers Air Plus Oil Mix Lubrication System are designed for applications where minute amount of metered lubricant is required to be applied on a surface. The lubricant is metered using an oil injector and is carried to the mixing block where the air and oil get mixed. The air breaks the oil into minute droplets and carries it to the lubrication point. The mixture is then passed through the nozzles creating a fine spray of oil which can be applied on any surface. Air oil mix systems are used for conveyors, high speed spindle, band saw machines etc. The advantages of air oil mix system over conventional mist system are: More reliable than conventional venturi type mist systems More eco friendly More easily controllable No dripping Air Oil Mix

Dual Line Lubrication System

Get Price Quote

Dual Line Lubriction System basically is adopted for the machine, where number of lubrication points to be fed by the grease are many and actuated at far distances. This system guarantees positive feeding of grease (of consistency upto NLGI-2) at different points on the machine under heavy pressure. All the points of the machine are connected through piping to the dose feeders and all the dose feeders are jointto the main pump through high pressure seamless pipe. Details: Pump-Plunger type driven by electric motor. Pressure upto 400Kg/cm2. Discharge-upto 250 grams per minute. ReservoirCapacity-upto 250 Litres. Dose Feeders with discharge 0 to 10 grams/cycle (Adjustable). This system is ideal for heavy engg. Fields where lubrication points are many and are located at far off distance like-Sugar Plants, Chemical Plants, Cements Industries, Nuclear Thermoelectric and Hydroelectric Power Stations, Furnaces, Iron and Steel Plants, Earth Moving Equipments, Milling Machineries, Coal and Mineral Industry, Mills and Crushers etc.

oil lubrication systems

58,000 - 620,000 Per Piece

1 Set (MOQ)

Oil Mist Lubrication System

Get Price Quote

The Oil Mist Lubrication System that we offer has a huge capacity. It is a pneumatically operated system. The air is prompted through On-Off solenoid valve. Airborne fog coats the bearings, gears etc. to form an oil film that reduces wear of machine parts. The air pressure required is from 4 to 6 kgcm2. Major Components : Oil Filling PortMist Outlet PortAir Inlet PortSolenoid Valve Features : DurableHigh strengthGood capacitySafe Usage