20 Feet Center Lathe Machine

1,500,000 - 1,700,000 Per piece

1 Piece (MOQ)

Gear Head Big Center Lathe Machine 20 Feet

2,400,000 - 2,460,000 Per piece

1 Piece (MOQ)

Best Deals from Centre Lathe

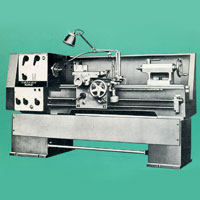

Center Lathe Machine

500,000 - 100,000 Per piece

1 piece (MOQ)

centre lathe

Get Price Quote

Light duty lathe machine 1370 MM., 1600 MM, & 1830 MM, Height of Centre 165 mm, Swing Over Bed 325 mm, Movement of Cross Slide 225 mm, Swing of Gap 500 mm, Length of Gap in Front of Face Plate 125 mm, Spindle Bore 40 mm.All The above specifications are approximate and subject to change without prior notice as improvements are made from time to time.

ALL GEARED PRECISION CENTRE LATHE

Get Price Quote

PSG 141 / A 141 is a light duty precision lathe which is renowned for its quality and performance. Ideally suited for production jobs and training purposes alike, its proven design guarantees several years of trouble-free service. The main spindle runs on precision taper roller bearings. The built-in safety features ensure reliable operation. The main drive gears are made from nickel-chromium steel, hardened and precision ground. The bed guideways are also flame hardened and precision ground.

Heavy Duty Center Lathe

Get Price Quote

HPSM’ Heavy Duty Lathes are renowned throughout the country to give minimum maintenance cost. Lathes are famous for precision jobs, accuracy and trouble free performance. One of the leading manufacturer, supplier and exporter of heavy duty lathe machines HP Singh Machinery Pvt. Ltd. understands the customer values and their exposers so they are making these machines with latest technology based.

centre lathe machine

Get Price Quote

centre lathe machines

Get Price Quote

R.P. Engineering Company is renowned as one of the dependable Centre Lathe Machine Manufacturers, Suppliers and Exporters from India. The use of high-quality Pig Iron and Steel in the manufacturing of the Centre Lathe ensures noteworthy attributes and compliance to the ISO 9001:2015 quality certification. With a customer-centric approach, we have ascertained the utmost level of customers’ satisfaction. Further, to meet the requirement of the application areas, we also specialize in offering Centre Lathe Machines in standard as well as customized specifications, provided by the buyers. APPLICATIONS OF CENTRE LATHE MACHINES Excellent performance by Centre Lathe Machines has plated important role in making it ideal for applications in sectors such as Steel Plants, Rolling Mills, Heavy Industry, Cement Plants, Paper Mills, Sugar Mills, Engineering Workshops, etc. Thus, our list of valued clients include some major names like Army Base Workshops, Ordnance Factories, Railways, NTPC, BHEL, NMDC, etc. FEATURES OF CENTRE LATHE MACHINES The below listed features of the Centre Lathe Machines that make it distinguished from the alternatives available in the market: Increase productivity Machining flexibility Superior feed capability Compact design Wear resistant Low power consumption Along with entraining huge orders from buyers in Indian states such as Sikkim, Bihar, Gujarat, Andhra Pradesh, Tamil Nadu, Assam, Arunachal Pradesh, Chhattisgarh, Goa, Haryana, etc., we are also praised for our excellent services to international buyers based in UAE, Saudi Arab, Sri Lanka, Nigeria, Bangladesh, Oman, UK, Kenya, etc.

Center Lathe Machine

Get Price Quote

Center Lathe Machine

Get Price Quote

We offer Center Lathe Machine which is used to manufacture cylindrical shapes from a range of materials including steels and plastics. Center Lathe Machine is one example of high precision engineering equipment. Center Lathe Machine is manually operated. Center Lathe Machine is used for manufacturing prototype products. Features of Center Lathe Machine Simple and low-priced High-powered and versatile Simplicity of operation combined with ease of maintenance Excellent metal cutting Wide range of inch-threads, module threads and extra metric threads

HI CUT TURNING CENTER CNC LATHE MACHINE

Get Price Quote

Precision Cone pulley Centre Lathe Machine

60,000 - 900,000 Per Piece

CNC Centre Lathe (LC 100 N)

Get Price Quote

Swing over Carriage 650 - 1000 mm Distance between centres 3 - 6 metre Max. wt of work piece 8 - 15 MT CNC System - Fanuc / Siemens (2 axes) Centralised lubrication 8 station programmable turret 2 Stage high efficiency transmission head stock Spring clamped - Hydraulic unclamped tail stock

centre lathe

Get Price Quote

Lathe machine Commonly known as machining center can perform multiple operations on a Metal piece like Cutting, Drilling, Grinding, Turning, Facing etc. with the help of different tools. These Tools are applied to the metal piece to Shape & create a Desired object having a symmetrical axis of rotation.Lathe Machines truly play a vital role in the industrial revolution in India as well as in the rest of the world. At Kwality Machinery we provide the best quality Lathe machines that are not only Durable, Accurate but are also easy to operate.

HIPAT CENTER LATHES

Get Price Quote

“HIPAT” CENTER LATHES are well suited for all common turning surfacing and screw cutting operation with accuracy conforming to nearby grade –1 limits. These heavy duty lathe machines are specially designed for continuous light and heavy duty job and to give prolonged efficient life these lathes are worthy of a place in every machine shop where economy of operation, precision and reliability are primary considerations. THE BED is made of close grained cast iron, having unusual strength and long wearing qualities it is machined and ground to finish and is well bracked to withstand vibration free operation, under heavy cutting load the casting are fully seasoned and removal gap piece is fixed. HEAD STOCK:- The flat seat of headstock over the bed is perfectly matched by precision hand scrapping. Its spindle is made from high carbon steel which rotates on two cylindrical split type gun-metal bushes of grade 1 composition both at the front and at the back for smooth running and perfect balancing the machines are also made with headstocks fitted with tapper roller thrust bearings. During the operation of the machine eight different feed movements can be arranged by means of specially constructed four step cone extraction V-Belt gear mechanism. The headstock gears have HELICAL HOB-CUT TEETH. THE APRON is of double well design with independent drive motion for feeds and screw cutting simultaneous arrangement of feed and screw cutting is prevented by an interlock mechanism. THE TAIL STOCK is of special and sturdy design, it is guided inverted ‘V’ and flat way bed independent of the saddle guides and has on off setting device for tapper turning. THE SADDLE is of heave design for stable rigid longitudinal movement. A compound rest accurately graduated is mounted on the saddle for conical turning and can be swiveled on either side. A revolving four way steel tool post is provided. The rack is of steel with machine cut teeth.

centre lathe

Get Price Quote

Centre lathe Industrial controllers from Siemens and Fanuc, Complete training and installation at no extra cost.

Center Lathe Machine

Get Price Quote

Made of carbon steel, Hardened & Ground. Also called full dead centers. The carbide HSS tips are brazed into the socket with a close tolerance for maximum strength.

Center Lathe Machine

Get Price Quote

We have emerged as the leading manufacturer and supplier of a distinguished range of Center Lathe Machine. This lathe machine is developed by our diligent professionals using top notch material in fulfillment with the standards of industry. Our provided lathe machine is demanded for turning in engineering, automotive and other industries. Also, our precious clients can avail this lathe machine from us in at industry leading prices within specified time frame. Features: Reliable functioning Easy to operate Sturdy design

Center Lathe Machine

120,000 Per Piece

Center Lathe Machine

Get Price Quote

Available in varied Bed Lengths with admit between Centres ranging from 1000mm to 3000mm. All major castings conform to suitable Grades & Main Parts have Hardness of 165 to 180 BHN wherever required. Bed Guidways are either flame Hardened & ground or hand scrapped to High Precision finish. Machine capable of cutting Whitworth, Metric, Diametral & Module Pitches. Machine conforms to accuracies as per IS : Standards.