Ceramic Foam Filters

6 - 1,200 Per No.

Ceramic Foam Filters are used for filtration, flow control and to avoid turbulence of molten metal in foundries. Depending on kind of metal, its temperature , flow rate, quantity and extent of filtration efficiency required we have to use different kind of Ceramic Foam Filters.

filter foam

Get Price Quote

Best Deals from Ceramic Foam Filter

Alumina Ceramic Foam Filter

Get Price Quote

Alumina Ceramic Foam Filters are mainly used for filtration of aluminium and alloys in foundries and cast houses.

Foam Ceramic Filters

70 Per Square Feet

300 Square Feet (MOQ)

filter foam

Get Price Quote

Ceramic Foam Filters

Get Price Quote

Ceramic Foam Filters are multiuse filters that are largely used in foundries. Foamed Ceramic Filters are basically used to keep the aluminum castings clean and pure and prevent it from being contaminated by nonmetallic materials. The ceramic Foam filters that we supply are made by well-reckoned firms, which ensure their optimum quality. They are highly durable and are efficient in performing their task. The filters are duly tested by our experts in order to guarantee their faultlessness. We are considered to be among the known Round Ceramic Foam Filters Suppliers in India. Applications : Used in aerospace applications, automotive applications, commercial casting, etc

Zirconium Based Ceramic Foam Filter

5 - 500 Per piece

Ceramic Foam Filters

Get Price Quote

filter foam

19 Per Piece

1 Box (MOQ)

We are manufacturer of quality product and serve you to best material. Ready stock all varient for deliver in your hand.

filter foam

450 Per Kilogram

500 Kg Kilogram (MOQ)

Ceramic Foam Filter

Get Price Quote

Ceramic foam filters are increasingly being used in aluminum industry these days. These are special filters made using materials like silica carbide and aluminum oxide to give them structural stability and to ensure resistance to thermal shocks. Ceramic foam filter is able to remove oxides from the surface of aluminum and thus increase casting quality. More and more aluminum sheets and foil manufacturers are today using these filters. Galaxy Enterprise is one of the biggest foundries as manufacturers of ceramic foam filters products in India as well as global industrial market. The company supplies these high quality filters to its clients involved with the production of aluminum sheets and foils.

Ceramic Foam Filter

Get Price Quote

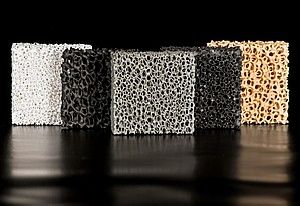

Our company is ranked among well-established Manufacturers and Suppliers of premium Ceramic Foam Filters. Made from superior-grade raw materials, our Ceramic Foam Filter are wear-tear resistant and render long service. They retain their physical properties even after extensive usage. Interested buyers can purchase Ceramic Foam Filters from us at market leading prices and expect timely delivery of orders. We can customize them as per specifications of customers to meet their unique demands. Sizes available : Available in All standard size in Round and square Shape.Raw Material Used : Silicon Carbide / Zirconia (10 PPI/20 PPI)Special Features : Better Quality of casting surface Improve Mechanical Properties Reduce amount of scrap Reduce cost of finishing operation Applications : Filtration of Cast Iron, Grey iron, Steel, Bronze, brass, Copper alloysBrief about product : Silicon carbide foam filter used for filtration in C.I./S.G. iron. Zirconia foam filter used for Filteration in Steel Industries where this product is used : C.I./S.G./Steel/ FoundriesColors & packaging available : 50 kg Bag

Ceramic Foam Filters

Get Price Quote

Ceramic Foam Filters manufactured by us are renowned in the market. Ceramic Foam Filters are a kind of effective molten metal filter. Three-dimensional connected mesh structure and high porosity of Ceramic Foam Filters have many advantages, for example, large surface area of slag collection, large inner surface area of filtering, small flow resistance, good filtering effect, etc. Ceramic Foam Filters are used to decontaminate the melting metal liquid, to simplify gating system, to improve the metallurgical structure of the castings, to reduce impurities of the castings, to improve casting quality rate, to reduce casting internal re-oxidation defects, to reduce the surface defects after machining of the castings, etc. Ceramic Foam Filters have to be kept in dry place, away from rain and heavy weights. Available In Alumina Foam FilterSilicon Carbide Ceramic Foam FilterZirconia Ceramic Foam FilterMagnesia Foam Filter

Ceramic Foam Filters

4,000 Per Piece

Ceramic Foam Filter

Get Price Quote

Ceramic foam filterAlumina Ceramic Foam Filters mainly for filtration of aluminum and aluminum alloys in foundries and cast houses. With their excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner

Ceramic Foam Filter

6 Per Piece

100 Piece (MOQ)

Ceramic Foam Filters

Get Price Quote

Dominant activity of the LANIK s.r.o. company is represented by manufacture and sale of the ceramic foam filters used under the trade name VUKOPOR® mainly in the foundry industry and in the primary aluminium production. Thanks to the mechanism of creation of the “filter cake” on the inlet filter side and thanks to depth filtration inside the ceramic matrix they represent the effective instrument enabling to reach metallurgical purity of the molten metal during the process of casting. The ceramic foam filters VUKOPOR® also calm mould filling, thus preventing creation of new inclusions and undesirable defects in the casting. The calming effect on mould filling is conditioned by conversion of turbulent liquid metal flow upstream the filter into the laminar flow downstream the filter. These VUKOPOR® filter features are conditioned by the open 3D structure of the ceramic matrix created by the system of mutually interconnected cells. The filters are characterized by a very good thermal conductivity, stability and resistance to sudden temperature changes. By applying ceramic foam filters, a higher quality of castings at lower costs for their manufacture can be reached in general: Increase of quality of castings: better surface of the castings improved mechanical features of the castings better dimensional and shape accuracy of the castings Lower costs: reduced rejection rate lower costs for machining of the castings

Ceramic Foam Filter

Get Price Quote

filter foam

Get Price Quote

We are engaged in providing all type of Filter Foam to our estimated client

Ceramic Foam Filter

Get Price Quote