12 Inch Ceramic Kharal Machine

25,000 Per piece

1 Piece (MOQ)

Ceramic Anilox Roller Ultrasonic Cleaning Machine

200,000 - 1,000,000 Per Units

1 nos. (MOQ)

CERAMIC ANILOX CLEANING MACHINE IT IS MOST SUITBALE FOR NARROW WEB ANILOX AS WELL WIDE WEB ANILOX CLEANING TOO ITS GIVES A EXELENT RESULT TO GET A QUALITY PRINTING AFTER DOING ANILOX CLEANING CONTACT FOR MORE DETAILS

Best Deals from Ceramic Machinery

Colorit Ceramic Oven

Get Price Quote

Colorit Ceramic Oven gives the designer countless opportunities to produce distinctive, colorful creations. The design possibilities are virtually limitless with Colorit Ceramic Oven. The color-fast tones are available in a number of nuances and can also be freely mixed. Since it is easy to work with, your imagination and love of experimentation will know no limits. The composite material with ceramic reinforcement can be applied quickly and easily, hardened permanently under blue light and ground and polished mechanically. The material is adhesion, shock-and wear-resistant, making it ideal for high-quality and individual designs. Appliances it includes: Dry articles inside Doit Ceramic Oven. Tray provided to keep jewellery articles. Detachable grills. Inside the tray, aluminium reflectors are used for better reflection. Two UV lights available for bigger surface. UV chamber with locking system provided to protect from UV light. Assembling process: Apply Premium Bond. Apply colorit color on hotplate. Apply colorit color on the article. Use lighter on piece. Dry articles inside Doit Cermaic Oven.

Cutting Machine for Ceramic Green Sheet

Get Price Quote

We are offering cutting machine for ceramic green sheet. G-cut 468 g-cut w12 (double blades type) w-types are applicable to rectangular work very accurate cutting is materialized with high rigidity mechanism. High accuracy image processing is materialized with the gray scale and by binary-coded regardless of shape or quality of target mark. Applicable to cutting various ceramic green sheets available in rich sizes and functions operation is easy. Applicable to various production systems compact and space saving g-cut4 applicable work size 50125mm standard working area max.100mm(4inch) applicable work thickness max t5.0mm standard cutter width w100mm standard cutter height×thickness(double-edged) standard h22.4×t0.10.3mm (user specification cutter and options) g-cut6 applicable work size 100175mm standard working area max.150mm(6inch) applicable work thickness max t5.0mm standard cutter width w150mm standard cutter height×thickness(double-edged) standard h22.4×t0.10.3mm (user specification cutter and options) g-cut8 applicable work size 150225mm standard working area max.200mm(8inch) applicable work thickness max t5.0mm standard cutter width w200mm,w150mm(zw) standard cutter height×thickness(double-edged) standard h22.4×t0.10.3mm (user specification cutter and options) g-cut w12 applicable work area 150300mm working area max.300mm(12inch) applicable work thickness max t5.0mm standard cutter width w200300mm

Pad Printing Machine For Ceramics Industry

65,000 - 350,000 Per piece

1 piece (MOQ)

We are the renowned manufacturer and supplier of a wide class of pad printing machine for ceramics industry. We provide following products under this category: high speed pad printing machine open inkwell pad printing machine four colour closed cup pad printing machine pad printing machine

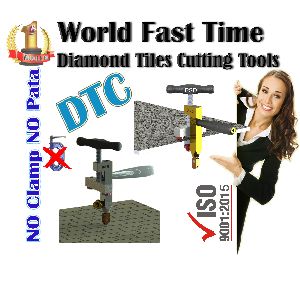

Ceramic Tiles Cutting Machine

1,000,000 Per Piece

1 Piece (MOQ)

Ceramic Slurry Mixing Machine

Get Price Quote

Ceramic Ball Mill Machine

500,000 Per Piece

Ceramic Press Machine

21,500 Per Piece

Ceramic Material Grinding Machine

700,000 - 1,000,000 Per per piece

1 number (MOQ)

Being a reliable name, we are focused towards delivering exceptional quality range, along with this, we follow strict guidelines and conduct regular quality examinations to ensure quality. We make sure that the offered lot complies with the stated quality norms, thus check the product quality on several stages. Approx. Price: Rs 9.56 Lakh / UnitProduct Details: Minimum Order Quantity - 1 Unit Carbide Grinding Wheel Size mm - 300 X 12 X 127 (OD X Thick x ID) Feed resolution - 0.005 mm on radius Height - 150 / 180 / 200 / 225 / 250 / 300 mm Main Table Width - 310 mm Max. Distance between Centers - 300 / 450 / 500 / 600 / 800 / 1000 / 1200 / 1500 / 2000 mm No. of Speed - 50 - 500 rpm Infinitely variable Tail Stock Taper - 3 / 4 / 5 mt Wheel Speed - 1000 rpm (for diamond wheel) Wheel width can be used - 10 to 40 mm Work head Swivel - 90 degree Work head Taper - 3 / 4 / 5 mt Features: Main Table travel (Hydraulic m/c): Hydraulic by precision hydraulic cylinder Main Table travel (manual m/c): Manual by precision rack pinion Table Swivel degree±6 In-feed mm Manual by precision ground feed screw Work head: Infinitely variable speed Guide Way coating: Turcite-B coated Wheel head bearings: Imported high precision angular contact = 2 Pairs Work head bearings: High precision imported bearings = 4 nos.

Ceramic Ball Mill Machinery

200,000 - 5,000,000 Per Set

1 Set(s) (MOQ)

Ceramic Ball Mill Machine

500,000 Per Piece

Ceramic Scrubbing Laser Marking Machine

430,000 Per Piece

ceramic tile glass cutting head Machine

920 Per Piece

50 Piece(s) (MOQ)

CNC Ceramic Peening Machine

Get Price Quote

MEC 2-axis CNC ceramic peening machine is designed to peen simultaneously 3 – 5 bucket profile blade for gas turbine. To generate the controlled compressive stress to the surface and to enhance the surface properties, increase fatigue strength, enhance lubricity by creating small pores, increase life of components and prevent galling, ferreting, cracking & corrosion. machine is suitable for peening job of maximum size 1000mm [L] x 500mm [w]. Standard: Large work envelope in cabinet Programmable 2-axis servo controlled gun mover Workcar mounted 5 turntables. Workcar extended outside of cabinet for easy loading Turntable speed variable as per peening intensity 5 Jobs can be peened simultaneously Very high production machine Vibratory sieve classifier unit for size classification Quick change & accurate positioned 15 suction blast guns Independent control of blasting guns Colored touch screen HMI & Siemens PLC panel Pneumatic grit recovery system Mechanical grit recovery system Efficient reclaimer with screening Easy part fixture change over Closed loop air pressure regulator Optional: Automatic shot peening media adder 2nd boor with turntable as 8th axis. Custom part holding fixtures Spiral type shot separator for shape classification

Ceramic Tile Sand Blasting Machine

Get Price Quote

Krishna engineers specialize in offering premium quality ceramic tile sand blasting machine that are made from wear resistant spares.

Ceramic Ball Mill Machinery

Get Price Quote

ceramic cutting machine

Get Price Quote

Since establishment, our organization has associated with leading traders and dealers. Thus, we serve patrons in Kolkata(India) without any problem. Having a wide network, we work on all Payment Terms as per the suitability of our patrons. Our payment procedures are reliable and legal. We do not impose hidden charges.

ceramic machinery

Get Price Quote

Ceramic Cup and Saucer manufacturing unit for sale. Plant is presently in running condition. It consist complete machinery such has tunnels of 140 ft, 92 ft & 88 ft length, ball mills, pulverisers, joly jigger machine, vibrater etc. for more details please contact us.

ceramic laser marking machine

Get Price Quote

Laser marking technology delivers permanent marks on metals, glass and ceramic parts for a diverse range of industrial and manual applications.The laser marking process is virtually all metals and plastics and various other materials with high contrast and without adding any undesirable substance. In most cases the typical physical effect of the laser marker induces a color change within the material so there is no surface modification by corrugations or burrs. Different marking methods and laser sources are used, to achieve the best results on every type of material. Flexibility of Laser Marking Laser marking is highly flexible process compared to any other marking process. Laser marking machine can mark any images and fonts without changing any punch, die, stencil etc. unlike other conventional process. Laser Marking features It offers a non-contact, abrasion-resistant, permanent laser marking onto almost any type of material. Laser marking process is Clean and Safe process –Chemical-proof, water-proof, oil, grease & fuel-proof. No pre or post processing – Laser marking can be done on finished products. Laser Marking is internationally Accepted as Quality Marking Standard. Visible ‘Pilot’ beam shows the laser marking location for fast, accurate setup. Laser marking helps significantly in cutting operating cost by reducing labor cost, tool cost, consumable cost, set up time, rejection improved cycle time One of the prime advantage of laser marking is that it can be automized and can be integrated with any online process. Use of Laser Marking Fiber laser marking machine marks on Ceramic with company names, brands, logos. With support of software variable serial numbers, batch numbers, Date Coding and 1D, 2D barcode can be laser marked. Text marking with all Windows True Type Fonts. Laser marking on Jwelery,Medical Instruments,Automotive,Consumer Goods,Electronics Parts and Giftware etc. Using Laser Marking,Clean Plastic and Metal Surfaces. Laser marking can be Engrave Deep or Fine. Laser marking tape designed for use on glass, ceramic, ceramic like and porcelain substrates. LIPI - Laser Marking Software Among its many features are ease-of-use, high performance, flexibility, and low cost that give you the best laser marking software on the market today. LIPI software is developed by our highly skilled professionals developers.Features of LIPI are...

CNC Ceramic Glass Bead Peening Machine

Get Price Quote

MEC CNC bead peening machine is designed for effective peening on aero engine component (Blade Airfoils). To generate the controlled compressive stress to the surface and to enhance the surface properties, increase fatigue strength by creating small pores, increase life of components and prevent galling, ferreting, cracking & corrosion.The system has capacity to peen upto 48" length of blade. SYSTEM FEATURES & BENEFITS Standard: 2-axis servo controlled reciprocation Variable speed turntable rotation Work car with manual winch for ease of job loading approach High volume pressure tank for long duration peening Quick change & accurate positioned 6 peening nozzles Colored touch screen HMI &Siemens PLC panel Efficient reclaimer with screening Easy part fixture change over Optional: Automatic shot peening media adder Closed loop air pressure control Magnetic separator Rotary lance drive Spiral type shot separator Vibratory sieve classifier unit Motorized work car movement

Ceramic Wafer Scribing Machine

Get Price Quote

We are engaged in manufacturing, supplying and exporting a wide range of Ceramic Wafer Scribing Machine to our clients at industry leading prices. Our range of machines is designed in accordance with industry standards and under the guidance of our experts. These Ceramic Wafer Scribing Machines find huge demand in the market. Features: * high quality * smooth functionality * long service life.

Ceramic Printing Machine

Get Price Quote

Table Top Model, Closed Cup Type, Economically priced, For small print areas, 100 % FESTO Pneumatics, Proximity switch based controls, Easy to shift, Suitable for Ceramic Steel Cup Rings, For small print areas within 60mm Diameter, Microprocessor based, Works on Single Phase Supply.

Ceramic Ball Mill Machine

650,000 Per Piece

Ceramics Cotton TFO Machine

Get Price Quote

Ceramic Ball Mill Machine

125,000 Per Unit

Ceramic Printing Machine

Get Price Quote

We are remarkable entity, engaged in offering high quality Ceramic Machinery. It is manufactured by our experienced professional in compliance with international quality standard from supreme grade components and latest technology. In order to ensure quality, this machine is thoroughly checked on various parameters of quality. We offer it in different technical specifications as per demands of the clients at rock-bottom price. Function: • It is used for flat screen printing Technical Features: • It is controlled by PLC, Chinese and English Display, easy to operate and change data • Thanks to the up and down structure, screen sticking on the tiles is reduced to a minimum • It is more suitable for print soluble - salt special large size with metal glaze • The high printing accuracy and remarkable output are guaranteed by clamp centering and different speed for transporting tiles Application: • Soluble - salt tile, rustic tile, porcelain tile with large size

ceramic machinery

Get Price Quote

SACMI is confident about providing unbeatable services anywhere in the world and has therefore opened another office in Morbi, Gujarat, where more than 250 ceramic factories make extensive use of Sacmi machinery, both new and old. The main purpose of opening this office is to provide better technical services and speed up the delivery of spare parts.

ceramic machinery

Get Price Quote

We, face impex pvt. Ltd., import and marketing of biscuit polishing machine, it�s a device changes the traditional grinding polishing process, a more stable and lower grinding technology. Tiles in the production process, due to raw material, technology, equipment, etc., there will inevitably be deformed on green body, particles, such as rough surface defects. Our equipment can be based on the degree of surface defects on green body to adjust the thickness and pressure belt equipment to meet customer requirements standard, can effectively improve product excellent rate, saving material costs and improve the brightness of the glaze. The device is a combination of the characteristics of the ceramic industries and production experiments the use of mechanical and electrical integration of modern automation technology we though years of research and developments of a new generation of biscuit polishing machine has become a very complete and good comments and trust from all customers.

Mild Steel Ceramic Ball Mill Machine

250,000 Per Unit