Royal-ACM Car AC Gas Charging Machine

125,000 Per piece

1 Piece (MOQ)

I-COOL 100 T AC Gas Charging Machine

150,000 Per Unit

1 Piece (MOQ)

Description: LCD Monochrome display Fully Automatic machine (Recovery, Recycling, Vacuum, Leak test & Recharging) Filter in recovery line to eliminate humidity & acidity Manual air purge from refrigerant tank Automatic High pressure protection for Compressor Audible indication / alarm Caution & error message / prompt Self diagnosis for checking the fitness of the machine Check valves to facilitate quick, easy & safe servicing Vehicle data base (up to 500 vehicles) Software update through USB interface Vehicle data update through USB interface Shock proof protection for load cells Quick coupler provision for new oil & used oil bottle

Best Deals from Charging Machine

ACS 261 AC Gas Charging Machine

192,800 - 235,000 Per Piece

1 Piece (MOQ)

Wooden packing this your material

AC Gas Charging Machine

2,800 - 2,999 Per piece1

powder charging system

100,000 - 500,000 Per No

1 Set (MOQ)

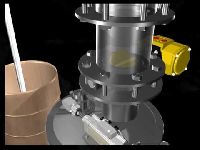

To charge powders from drums/ sacks to silos/ reactors at rates exceeding 2000 kg/hr and over 25 meters. Easy to use. Easy to wash. You can dismantle the whole system in under 3 minutes for washing. No bulky valves/ electrical to be dismantled. All controls are mounted in convenient Starter box. Easy to replace PTFE cartridges for filtration. Optional HMI for multi product setups. CIP/ SIP options possible. High Technology powder conveying in one simple package.

AC Gas Charging Machine

169,000 Per Piece

5 Piece (MOQ)

AC Gas Charging Machine

Get Price Quote

AC Gas Charging Machine

Get Price Quote

With the complete help and support of our team members, we deliver product that is certified and in compliance with the standards. It is due to our guarantee of providing damage-free products to the clients; we are highly in demand amongst the buyers. Our packaging experts keep a stringent check on the entire packing procedure ensuring the same.Features : Automatically recycle remaining refrigerant. After treatment, the recycled remaining accords with SAE standard. Automatically separate and drain A/C system oil. Electro-magnetic valve controls the adding of A/C system oil. Automatically treats the incondensable gases in refrigerant. Electronic balance measure the recycled and recharged refrigerant during the whole process. After one set up. The whole process of vacuuming and recharging of the refrigerant will be completed automatically. The pressure and temperature comparing table can tell if automobile air conditioner operates property. Characteristics : The whole process in controlled by micro-computer, electro-magnetic valve design prevents damage from liquid flow. Fast and convenient self-sealing connections. Automatically reminding of problem checking and alarming, present operation states and daily maintenance. Technical Data : Recovery Speed - 4.1 Gm/Sec Vacuum Speed - 2.0 ltr/Sec Recycle Speed - 8.0Gm/Sec Charging Speed - 22Gm/Sec Tank capacity - 10 kg Drier filter capacity - 68 kg Scale Accuracy - +/- 1 gm

powder charging system

Get Price Quote

The Vacuum transfer system is unique dry material transfer system for dust free and avoid to human touch. The vacuum transfer system is used in Pharmaceutical, Food, Agro Chemical, Sugar Industries and chemical. The system is use full for inline milling, sifting, blending, loading and unloading. The principle of vacuum transfer has been proven to be a better way to move many types of material and a giant step over manual handling. The technology exists for moving virtually any material that can be pulled through a hose or tube. The system is consisting of Blower, Vacuum receiver system with filter, cyclone filter and Pipe. The vacuum conveying systems designed specifically for the direct charge loading of blenders, mixers, sifter, milling, reactors or any vessel capable of withstanding a vacuum. The vacuum system can be provided mobile type with lifting provision to move one room to another room for loading and loading any machine.

intelligent mini charging robot cleaning machine

400 - 450 Per piece

Fully Automatic Aircon Service System

Get Price Quote

Scrap Charging Machines

Get Price Quote

SCRAP CHARGERS are suitable for charging the scrap material in to the melting furnaces of SCRAP RECYCLING / ALLOYING units where scrap charging time can be drastically reduced as against manual charging. Charging machine not only reduces manpower required for charging but also makes it a safe operation and reduces possible chances of accidents which may cause because of explosion or metal splash. Since charging time is significantly reduced, door open time is also reduced which straight way results in energy saving as most of the heat contained is normally lost when door is kept open for manual charging which requires more energy to compensate. Distinct benefits of FURNTECK’s SKLENNER / Reverbratory furnaces 1.Melting and Holding is done in single chamber. 2.No blind corners in refractory which allows easy and thorough cleaning of furnace. 3.Metal tapping is possible through PLUG SYSTEM / HYDRAULIC TILTING. 4.Furnace can be optionally equipped with AIR RECUPERATOR. 5.Large full width door access can be provided in order to clean and charge furnace easily

vacuum dry charging machine

Get Price Quote

1. Capable of dry charging automotive and industrial battery negative plates. 2. Batch process gives consistent quality plates with over ninety per cent free lead content. Plates have high capacity charge retention. 3. No environmental problems. 4. Compact size with low layout cost. 5. Automatic cycle duration of eight to ten hours. 6. Rugged construction. 7. Easy to operate. 8. High productivity. 9. Low maintenance costs. 10. All work instructions documented and given. 11. Maintenance and service manual supplied along with the machine. 12. Operator training provided at our works. 13. Standard components used in the manufacture. 14. All safety parameters considered. 15. No fumes or residual waste. 16. PLC and data logger ensure accurate process control. FAQ's 1. What are the advantages of selling a dry charged battery as against a dry uncharged battery assembled with formed plates? A battery dealer is a person who never wants to displease his customer and at the same time wants to have the maximum business. This is not unusual in any region and understandable from the businessman’s point of view. If a battery manufacturer gives the dealer a dry charged battery the manufacturer and dealer derive the following benefits:- The rest period after acid filling is around 2 hrs. as against 12 to 16 hrs. There are no batteries lying around waiting for charging and occupying costly floor space. The charging duration after acid filling is 8 to 12 hrs. as against 55 to 72 hrs. The need for capital investment in costly chargers is eliminated. The charge input is 1 C as against 3 to 5 C – thereby charging cost is lowered. The inventory carrying cost at dealer’s premises w.r.t. charged battery holding in stock is substantially reduced. The quality of batteries delivered to customers is good since batteries do not get heated during initial charging thereby damaging the internal components of the battery. Due to this reason the battery warranty claims are reduced / eliminated. The possibilities for export of batteries / battery plates open up leading to a wider market penetration. 2. Is it possible to use the dry charging machine for drying industrial battery (stationary & traction) negative formed plates ? Yes – the machine can be used to dry the formed negative plates of any type of lead acid battery. I.e. automotive, motor cycle, SMF, stationary, semi traction or traction battery. 3. In what way is a dry charged battery different from a battery made with formed plates ? In the case of battery made with formed dried plates the positive plates are fully charged whereas the negative plates have discharged after formation due to the oxidation reaction which is an exothermic reaction that has taken place when the plates were taken out of the formation jars. Due to this phenomenon batteries made with formed plates need a long duration of charging at a slow rate of charging i.e. low current input. The input in terms of Ah is also high. Basically the negative plates need to be charged without heating up the positives which are already fully charged. In the case of battery made with dry charged formed negative plates and dried formed positive plates the batteries can be commissioned fast since the negatives are not discharged after formation. 4. For how long a duration do the negative plates stored as plates retain its dry charge characteristics? The retention of dry charge characteristics in negative plates shall depend on the method of storage of plates and the nature and quantity of certain additives in the negative paste mix. If the plates are not exposed to atmospheric moisture and oxygen the period of storage can be as long as 12 to 15 months. It is therefore necessary to cover the fully dried cool plates with polythene wrapping in a suitable manner. Dried silica gel pouches in cotton bags help in keeping plates dry. Further at the time of negative paste mix preparation an addition of oil or stearic acid is recommended. This forms a protective layer on plate surface preventing oxidation of negative plates with a consequent loss of dry charge characteristics. 5. For how long a duration does an assembled battery having dry charged negative plates retain its dry charge characteristics? The retention of dry charge characteristics in an assembled battery shall depend to a great extent on The residual acid in the negative dry plates. The residual acid in the dried positive plates. The residual moisture in the dried positive plates. The sealing of vent holes of the battery to prevent moisture ingress. Since moisture from positive plates can travel to negative plates and start the oxidation process it is necessary to dry the positive plates also thoroughly before assembly.Residual acid in either positive or negative plates can cause deterioration of dry charge characteristics since the hygroscopic sulphuric acid can attract the atmospheric moisture leading to oxidation of negative plates 6. What is the quality parameter which indicates that the dried plates are of acceptable nature? The free lead content in the active material of formed dry negative plates – taken out of the machine after correct processing – is an indicator of the quality of the plate. 7. How can this free lead content be verified? This can be verified by chemical testing in the laboratory. In case detailed procedure of testing is required please contact M/s Unik Techno Systems Pvt. Ltd.. 8. Is there any other simple method which indicates that the dried negative plates are of acceptable quality? A simple indication is available if it is observed that the assembled battery temperature does not increase more than 8 degree Celsius to 10 degree Celsius. sp.gr. does not fall by over 0.02 to 0.04 points. over a one hour period after filling of acid in the battery. 9. How important is the washing of negative plates prior to dry charge process? It is important to wash the negative plates free of acid and check whether the wash water pH is between 5.5 to 6.0 prior to loading the plates on to the dry charging chamber. Please note that it is equally important to load the washed plates into the machine within an hour of such a complete wash – free of acid. In case the plates have to be stored for a long period in water after washing, it is necessary to retain some acidity in the water. Hence it is recommended to do the washing in two stages. In stage one wash plates such that the wash water pH is around 4.5 to 5.5. Keep negative plates in a tank of such an acidic water. As and when the negative plates are to be dried and approx. an hour or so prior to loading into the machine the second stage of washing can be carried out i.e. plates can be washed to a pH of 5.5 to 6.0. If the plates are not washed completely free of acid prior to loading on to the machines the seals of the vacuum pump shall get damaged leading to machine breakdown and production downtime.

AC Gas Charging Machine

195,000 - 215,000 Per piece

1 piece (MOQ)

Ac Charging Machine

Get Price Quote

we are engaged in the manufacturing and exporting of unsurpassed quality ac charging machine which have been extensively appreciated of their high performance. the finest grade raw materials used while fabricating the auto ac charging machine ensures of a long life and precise results in every application. the ideal scale resolution and recovery rate of our ac chargers makes them a highly reliable product in the market. over the years, we have carved a niche as one of the principal ac charger exporter and supplier. features : long life easy operationseffortless installationlow maintenance model : pac 500

AC Gas Charging Machine

Get Price Quote

Recycle remaining refrigerant in the automobile air conditioner. After treatment, the recycled refrigerant accords with SAE standard. Separate and drain AC system oil. Electro - magnetic valve controls the injection of AC system oil. Automatically remove the incondensable gases in refrigerant. Electronic balance measures the recycled and recharged refrigerant during the whole process

ARO Car AC Gas Charging Machine

180,000 Per unit

charging machine

Get Price Quote

We are offering high quality Screw Conveyors. These conveyors involve a specially designed helical screw, which is responsible for limited distance transportation of heavy Abrasive and granular material in industrial processes. If temperature is there we can supply with double water jacket for long life of Screw. These offer excellent reliability in extreme conditions and are intended for long production runs

AC Gas Charging Machine

110,000 Per Piece

01 Piece (MOQ)

gas charging machines

Get Price Quote

We are one of the leading in the Industries who make its own design in gas charging machines & evacuating machines on its own. We design four innovative models especially for technician who make work easy & quickly for themselves. We design: Mini Gas Charging Unit Standard Gas Charging Unit Commercial Gas Charging Unit Portable Gas Charging Unit

powder charging system

Get Price Quote

Powder Charging System is the lean-phased vacuum-conveying mode, which achieves material transfer by introducing the material into the moving stream of air at the desired rate. The PCS uses both vacuum and pressure to move powders and dispenses them with the help of gravity. It can charge powders from drums/ sacks to silos/ reactors at rates exceeding 4000 kg/hr and over 25 meters. . The system ensures the safe transfer of powdered material directly into mixing vessels or reactors, reducing dust generation and wastage as compared to manually charging powdered material through a manhole or a chute. The main purpose of having this contained system is to prevent operator exposure to the sensitive powders which may be hazardous to health and to minimize environmental exposure and cross-contamination to the product. Being operated on a vacuum principle the system is intrinsically dust free. The airflow is promoted by creating negative pressure throughout the system using the vacuum pump.

AC Gas Charging Machine

Get Price Quote

Automatic Recovery, Vacuum Recycle, Puyrify, and Recharging System.Digitally monitoring of pressure.High controlled LCD Display alarm for high pressure, Large size gauges for easier reading.

charging machine

Get Price Quote

Our entire range of products is produced as per international quality standards. Therefore, they are dependable and worth the price. Making available the finest assortment of products, we make sure that the range is kept safe in our inventory in Rudrapur(India).

AC Gas Charging Machine

Get Price Quote

Most people assume air con servicing is needed only when system is not throwing cold air…this is false. It is recommended that you should recharge your air conditioning system every 2 years with gas and lubricant, in order to keep it running efficiently. Overlooking AC Gas Recharge & maintenance might cause the engine to work harder and in turn use more fuel.

charging machine

Get Price Quote

We are offering high quality Screw Conveyors. These conveyors involve a specially designed helical screw, which is responsible for limited distance transportation of heavy Abrasive and granular material in industrial processes. If temperature is there we can supply with double water jacket for long life of Screw. These offer excellent reliability in extreme conditions and are intended for long production runs.

powder charging system

Get Price Quote

Pneumatic Automatic powder charging system is provided duly mounted on a swiveling davit interlocked with sensor to safeguard against blender. It is provided with a SS suction nozzle coupled to a flexible PVC food quality conveying pipe to enable for direct suction of the powder from container which will be discharged in blender and on complete charging of batch or maximum upto 70-80% by volume, filter bag of charging system may automatically be cleaned by auto reverse pulse jet mechanism thereby safeguarding against operator dependency, charging system may be swivelling on side and locked in that position which will actuate the sensor for that position, a dummy cover to be clamped on charging hole & homogeneous blending action can be initiated by starting the blender operation. After necessary blending period the material can be discharged & collected from bottom into container by manually opening the butterfly valve. The entire auto charging system is a tool free assembly.

Ac Charging Machine

Get Price Quote

Technical Specifications: Weight : 95kg (including Gas tank) Height : 1016.0mm Width : 0mm Depth : 6mm Switches : heavy duty Control panel : LCD with digital keypad Weight range : 50 grams to 30 kg Pressure Gauges : specific to refrigerant Valves : quarter turn Italian type Compressor : hermetic (1/5) Vacuum pump : double stage, compressor for pressure Cooling fan : 220V AC, high speed Charging hoses : standard, specific to operation Refrigerant tank : 10kg standard Power source : 220V AC Wheels : rubberized coaster type Benefits: More AC cooling Gas saving Efficient vacuuming High earning by recovery of refrigerant Assured liquid and dry refrigerant Efficient working with no efforts Less return complaints Features:- Fast recovery of refrigerant In-built pressure leak test system (optional) Separates oil, moisture , acid & other contamination from recovered refrigerant Double stage recycling of recovered refrigerant Double stage vacuum pump ensure maximum and efficient vacuuming of the system Digital weight display of recovered/ charged refrigerant Auto cut on vacuuming & recovery Auto cut on required charged refrigerant Refrigerant charging by pressure different Air purge on a click of the button Built in oil charging Built in system’s oil catch bottle with measurement marking Refillable refrigerant tank Scale measurement +2.5grams for accurate measurement Double sided powered coated, heavy duty sheet metal chassis No bay space required Comes with all required accessories

Scrap Charging Machine

Get Price Quote

Entec Industrial Furnaces Pvt. Ltd highly engaged in offering a wide range of industrial machines to our clients in all over the globe. We are one of the reliableScrap Charging Machine manufacturers, suppliers, and exporters of India. These are suitable for charging the scrap material in the melting furnaces of scrap where charging times can be drastically reduced as against manual charging.This is a power saving product based on advanced technology, which is highly demanded in the globalized market for its efficient performance. This is manufactured under the guidance of our expertise at our inbuilt manufacturing facility, which ensures its long lasting performance.Being Furnace Scrap Charging Machines manufacturers, suppliers, and exporters of India, we never compromise in the quality of our product and never give you a chance of complaining. We also provide safe transportation for your consignment without any delay. What’s more, are you waiting for? Send enquiries to place your order or to get more information. Features Of Scrap Charging Machine Unbeatable quality Heavy construction Efficient performance Long-serving life Minimum maintenance Widely demanded in various industries Suitable for melting scrap

AC Gas Charging Machine

Get Price Quote

Autonics machines (india) has earned the identity of being reliable manufacturer, exporter and supplier of AC Gas Charging Machine in haryana. Our ac gas charging machine has various features such as high performance, energy-efficient, reliable, etc.

Aerosol Gas Charging Machine

150,000 - 170,000 Per Piece