Lime Slacker

Get Price Quote

Details: Strong crushing ability Full automatic hydraulic system Types of crushing cavity Features: Finished in the perfect manner Quality specification Equipped with rotating cylindrical vessel The major applications of hydrated lime are summarized below :- Building material Metallurgical processes Chemicals Pharmaceuticals Sanitation Paper and pulp Food processing

Swimming Pool Chemical Feeder

Get Price Quote

1 Piece (MOQ)

Best Deals from Chemical Handling Equipment

Swimming Pool Chemical Dispenser

4,000 Per piece

100 piece (MOQ)

Lime Slaker

Get Price Quote

Lime Slaker manufactured by us is fabricated from M.S. We use finest material to fulfill our Client’s requirements. Our Lime Slaker is rotary type mounted on wheels to hold the capacity of 600 kg/hr to 1500 kg/hr. We offer our Lime Slaker with Vibro Screen and Lime Tanks. Our Lime Slaker is design in such a way that it provides efficient and trouble free operations. Features : High PerformanceGood Production CapacityHigh Quality Machinery Advantages : CompactAffordable Price RangeLow Maintenance

High Expansion Foam Generator (mini Turbex)

Get Price Quote

- Newage Industries are leading manufacturers, exporters, and suppliers of High-Expansion Foam Generator (Mini Turbex) which is high expansion and smoke exhauster. The High-Expansion Foam Generator offered by us is made of optimum quality stainless steel. The High-Expansion Foam Generator has large foam capacity and water pressure operated turbine. - Salient Features Nylon foam making net63mm Al. alloy male inst. Inlet68m3 per minute foam capacity at 7 bar Expansion 1:300 620mm high, 460mm width, 300mm deep Approx. weight 17 kg. - Complete With One inline inductor One 30m polythene ducting One reinforced plastic ducting (7.5mtrs) for smoke extraction.

process plant equipments

Get Price Quote

We are also manufacturing Process Plant components as per the customer drawings. It includes Fabrication and complete process of Vibrating Tables, Scoop Rings, TAD Dampers, Gear Guards, Elevator Buckets and Scraper Blades, Impellers etc. Machining of Special Shafts as per the customer drawing and with special machining processes like Grinding , Milling , Hardening etc.These are manufactured based on the client requirement and can be delivered within the specified delivery time.

Foam Generator

Get Price Quote

We have emerged as a noteworthy Foam Generator Supplier. We are engaged in making available precision engineered Foam Generator that is equipped with ultra modern features. The offered Foam Generator is very easy to use and gives hassle free performance. Foam Generator, that we provide, is energy efficient as well.

Chemical Process Equipment

Get Price Quote

Our entire range is made to go through to extreme quality control checks to make sure they adhere to standards of global management systems. As we have marked a distinct name in the market, we are recognized as the trusted organization for supplying quality Chemical Process Equipment.

Foam Generator

Get Price Quote

Stainless steel foam washing machine has a novel design ,the foam is exquisite and equal, low waste and high effect,it is easy to move,the tank is stainless steel,can be used for a very long time. this kind of cleaning machine is so popular in the car cleaning and hairdressing industry , gas station service ,and so on .

Blue Dye And Marker Injection Skid

Get Price Quote

1 Piece (MOQ)

Blue Dye And Marker Injection Skid Turbine meter generates pulses based on the Flow of product in the main pipeline header. These pulses are processed by the PLC for flow measurement of main product (SKO). Based On flow sensed in the main header, PLC will trigger a Start command for the Blue Dye pump (Motor) and also Open command for the solenoid (On – Off) Valves on the delivery header of Blue dye skid. Blue dye will then be injected into main product line as per a pre set ratio (say – 25 PPM) or by putting PD meter which will be connected to PLC. For every pre determined quantity of SKO (say 500 Litres) flowing through the header, the PLC Shall permit the solenoid (On - Off) valve on the blue dye delivery line to be open for a given Length of time in order to dose required quantity of blue dye. The flow rate of blue dye is always a constant parameter based on the settings of the positive displacement blue dye pump. Based on this flow rate, PLC shall monitor the time duration for which the solenoid (On – Off) valve shall Be in open condition. Once blue dye is dosed as per pre set ratio, PLC shall generate Close Signal For the solenoid (On – Off) valve. Quantity of blue dye pumped by the blue dosed is determined By the fixed flow rate of the positive displacement Blue Dye Pump. The dosing shall continue in cycles for every pre determined quantity (500 Litres) of the main product passing through the header. As the main product (SKO) flow rate increases, the blue dye dosing cycles will increase accordingly. Ratio and cycles can be changed manually through the PLC. Pressure in blue dye line is maintained by back pressure valve and sensed by pressure switch. Suitable HMI in the control unit shall be built to provide custom displays like Blue dye Motor Status, Solenoid (On – Off) Valve Status, Blue dye Agitator Status, Flow – rate of product in the main header, Quantity of blue dye dosed (based on no. Of times solenoid valve is energized) etc. Overview Of Blue Dye Dosing Panel Blue Dye Dosing panel ensure correct amount of Blue Dye dispensed at pre defined quantity set in PLC. The HMI provide display of On/Off status of Pump / Agitator, On/Off Status of Solenoid Valve, Flow rate of Main Product, and Quantity of blue dye dosed based on no of time solenoid valve is energized. The system operates under following two modes as per selection from Local HMI. HMI Provides Two Mode Of Operation Auto injection Manual injection This Mode Settable By User From Local HMI 1. Auto Mode Auto mode operates for Ratio Control Mode as per Selection.  For Ration control, the flow of main product (SKO) through its Turbine flow meter (Pulse generator) is Fed as an input to the PLC system. Pulses are processed by the PLC for flow measurement of main product.  Blue Dye dosing panel ensure that a correct amount of Blue Dye is dispensed with respect to Main product at all times on line in a predefined ratio ( set in the PLC) throughout the load cycle.  When a pre defined quantity packet for main product passed then respective Blue dye SOV will be energized for a given length of time for a dosing of Blue Dye. On dosing of pre defined quantity for Blue Dye Product, SOV will be de energized by PLC.  The flow rate of Blue dye shall be always a constant parameter based on setting of the positive displacement blue dye pump. Based on this flow rate, time duration shall be decided and fed to PLC as set point for solenoid ON time.  The Cycle continues during receipt in frequently dosing of packets of qty.  2. Manual Mode Manual mode can be operated from Local HMI User can Start / Stop Pump / Agitator manually. User can on / off Solenoid Valve manually. Major Components Of BLue Dye / Marker Dosing Skid Tank with Level Indicator. Diaphragm Pump with FLP motor. (02 Nos.) Back Pressure Valve, Non Return Valve, Ball Valve, Needle Valve. Agitator with Motor. Pressure Switch. Solenoid Valve. Pulsation Dampener. PLC Required Electrical like Junction Box, Pump selector switch, Isolator. Turbine meter with Flow Straightener. Strainer Cum Air eliminator in SKO line. Base Skid. Pressure gauge with isolation valve. PD meter – Optional. (if metering base injection is required)

Cyclohexene Chemical

70 - 95 Per LITER

50 Litre (MOQ)

chemical dispensers

55,000 - 85,000 Per 100gm

Chemical Process Equipment

450,000 Per piece

Chemical process equipment refers to a wide range of mechanical and electrical devices used in the chemical industry to carry out various unit operations and processes involved in the production, transformation, and handling of chemicals and chemical products. These equipment are designed to handle different types of chemical reactions, separations, heat transfer, and other essential processes.

Foam Generator

Get Price Quote

Foam Generators (FCH *-250 are designed to expand foam solution into millions of tiny bubbles in which the foam solution is expanded in volume to a range of 200:1 to 450:1 approximately depending on the generator selected, solution flow rate, foam concentrate and the operating pressure. The extinguishing mechanisms of FIRECHEM HiEx Foam Generator (FCH* -250) involve a combination of the following: Free air movement necessary for continued combustion is reduced. Water content of the foam being converted to steam dilutes the oxygen concentration to a level below that necessary to support combustion. Cooling to a temperature below the combustion point or auto- ignition temperature of Class A or Class B fuels occurs as water is converted to steam. Reduced surface tension of the foam solution draining from expanded foam penetrates into Class A materials extinguishing deep seated fires. Insulating and heat reflective properties of the foam blanket provide a heat shield preventing fire spread extinguishing deep seated fires.

Chemical Machinery & Equipments

Get Price Quote

we mfg and supply all types of chemical plant equipments in GMP and NON Gmp grade in SS316 as well as SS 304 from 100ltrs to 25000ltrs capacities ,reactors, blenders, mixers, storages tank, heat exchangers, condensers, coolers, product coolers,reboilers, receivers, filters, extractors,fermenters,reaction kettles, reflux chambers, distillation column, simple distillation, bubble  cap distillation column, packet column, blending tank, ribbon blender, paddle blender blender, resin kettle, resin reactor, stainless steel reactor, process reactor, jacketed reactor, limped coil reactor,

chemical process equipments

25,000 - 5,000,000 Per piece

1000 Litre (MOQ)

Price on demand, chemical process equipment

chemical plant equipment

Get Price Quote

Leveraging on our rich industrial experience, we are enlisted among the nonpareil Manufacturers, Exporters and Suppliers of Chemical Plant Equipment. Our range is inclusive of mechanical crystallizers, pcm mixers, benzol scrubbers, crude benzol column and many more. The entire range of the equipment is reasonably priced by us. Details : Mechanical Crystallizers. PCM Mixers. Benzol Scrubbers. Crude Benzol Columns. Primary Gas Cooler. Washing Agitators. Saturators. Heaters & Coolers. Mehanical Decanters. Anthracene Fraction Rectifying Columns. Storage Tanks. Tar Distillation Plant Equipment. Ammonium Sulphate Plant Equipment. Electrostatic Tar Precipitators / Detarrers. Final Gas Coolers Beekay has tied up with M/S Hutin Projekt, Czech Republic for offering State of Art By Product Plants in India.

Chemical Process Equipment

20,000 Per Litre

1 Litre (MOQ)

We are offering Chemical Process Equipment. we are professional laboratory that specialises off chemical solution and products to clean black notes,green and white notes for mores information kindly revert back with you email address or you contact my phone number to have full details

Foam Generator

Get Price Quote

Foam generator makes foam for CLC using foaming agents. Foam generators come with corrosion resistant coated steel body, timer, air compressor, and lance units.Features : Adjustable density of foam Automatic time setting to off the motor Digital foam generator Easy & cost effective maintenance and operation Daily take 100 cubic meters with our foam generator 1 HP single phase motor Inbuilt control panel Less power consumption Corrosion resistant Foam generator with lance unit Adaptable to different kind of foaming agents

rebaring chemical dispenser

2,000 Per piece

Chemical Dispenser/gun is used to dispense rebarring chemicalChemical Dispenser/gun is used to dispense rebarring chemical

Blue Dye And Marker Injection Skid

100,000 Per Piece

1 Piece (MOQ)

Blue Dye And Marker Injection Skid Turbine meter generates pulses based on the Flow of product in the main pipeline header. These pulses are processed by the PLC for flow measurement of main product (SKO). Based On flow sensed in the main header, PLC will trigger a Start command for the Blue Dye pump (Motor) and also Open command for the solenoid (On – Off) Valves on the delivery header of Blue dye skid. Blue dye will then be injected into main product line as per a pre set ratio (say – 25 PPM) or by putting PD meter which will be connected to PLC. For every pre determined quantity of SKO (say 500 Litres) flowing through the header, the PLC Shall permit the solenoid (On - Off) valve on the blue dye delivery line to be open for a given Length of time in order to dose required quantity of blue dye. The flow rate of blue dye is always a constant parameter based on the settings of the positive displacement blue dye pump. Based on this flow rate, PLC shall monitor the time duration for which the solenoid (On – Off) valve shall Be in open condition. Once blue dye is dosed as per pre set ratio, PLC shall generate Close Signal For the solenoid (On – Off) valve. Quantity of blue dye pumped by the blue dosed is determined By the fixed flow rate of the positive displacement Blue Dye Pump. The dosing shall continue in cycles for every pre determined quantity (500 Litres) of the main product passing through the header. As the main product (SKO) flow rate increases, the blue dye dosing cycles will increase accordingly. Ratio and cycles can be changed manually through the PLC. Pressure in blue dye line is maintained by back pressure valve and sensed by pressure switch. Suitable HMI in the control unit shall be built to provide custom displays like Blue dye Motor Status, Solenoid (On – Off) Valve Status, Blue dye Agitator Status, Flow – rate of product in the main header, Quantity of blue dye dosed (based on no. Of times solenoid valve is energized) etc. Overview Of Blue Dye Dosing Panel Blue Dye Dosing panel ensure correct amount of Blue Dye dispensed at pre defined quantity set in PLC. The HMI provide display of On/Off status of Pump / Agitator, On/Off Status of Solenoid Valve, Flow rate of Main Product, and Quantity of blue dye dosed based on no of time solenoid valve is energized. The system operates under following two modes as per selection from Local HMI. HMI Provides Two Mode Of Operation Auto injection Manual injection This Mode Settable By User From Local HMI 1. Auto Mode Auto mode operates for Ratio Control Mode as per Selection. For Ration control, the flow of main product (SKO) through its Turbine flow meter (Pulse generator) is Fed as an input to the PLC system. Pulses are processed by the PLC for flow measurement of main product. Blue Dye dosing panel ensure that a correct amount of Blue Dye is dispensed with respect to Main product at all times on line in a predefined ratio ( set in the PLC) throughout the load cycle. When a pre defined quantity packet for main product passed then respective Blue dye SOV will be energized for a given length of time for a dosing of Blue Dye. On dosing of pre defined quantity for Blue Dye Product, SOV will be de energized by PLC. The flow rate of Blue dye shall be always a constant parameter based on setting of the positive displacement blue dye pump. Based on this flow rate, time duration shall be decided and fed to PLC as set point for solenoid ON time. The Cycle continues during receipt in frequently dosing of packets of qty. 2. Manual Mode Manual mode can be operated from Local HMI User can Start / Stop Pump / Agitator manually. User can on / off Solenoid Valve manually. Major Components Of BLue Dye / Marker Dosing Skid Tank with Level Indicator. Diaphragm Pump with FLP motor. (02 Nos.) Back Pressure Valve, Non Return Valve, Ball Valve, Needle Valve. Agitator with Motor. Pressure Switch. Solenoid Valve. Pulsation Dampener. PLC Required Electrical like Junction Box, Pump selector switch, Isolator. Turbine meter with Flow Straightener. Strainer Cum Air eliminator in SKO line. Base Skid. Pressure gauge with isolation valve. PD meter – Optional. (if metering base injection is required)

Chemical Laboratory Equipment

Get Price Quote

While purchasing the product from us, you can choose to make payment through any mode. Our personnel will assist you to pay for your purchases conveniently. The raw materials that are used for the production of our finished products are acquired in minimally processed or unprocessed states; these are free from impurities as well.

Lime Slaker

Get Price Quote

Based in Muzaffarnagar, Uttar Pradesh, we are one of the leading manufacturers, suppliers and exporters of Lime Slakers. Our Lime Slakers are used for preparation of milk from lime, for the process of preparing good quality sugar. Our Lime Slakers can be manufactured for plant whose capacity ranges from 200 TCD capacities to 10000 TCD. These are highly durable and reliable products designed for a long life. We offer Lime Slakers at the most competitive prices.

Foam Generator

Get Price Quote

We are offering Foam Generator. Foam Generator is used to generate the Foam. Automated Timer for automatic control. Foam Output 200 to 400 Liters per minute. Density of foam minimum 80Grm/Liter ( Depends on Quality of Foaming Agent). 4 Kg Air Presure is required for it.Air compressor is not supplied by our company.

chemical handling equipments

Get Price Quote

Wide category of products available, brands option with competitive price. all types of chemicals industry can be benefitted with the availability of products

Aluminium Foam Generator

5,500 Per Piece

5 Piece (MOQ)

Manhole For Process Equipments

Get Price Quote

We are the manufacturer of manholes like Stainless Steel and Carbon Steel which are used in Chemical Industries for Process Equipments. We also manufacture manhole as per the Clients specification and design.

frp equipment

Get Price Quote

The Material of Construction FRP Using General & Superior Vinylester Resin. FRP Using Bisphenol Resin. FRP Using Isophthalic Resin. FRP With PVC And CPVC Liner FRP With PVDF, FEP, ECTFE, PFA, MFA Liners FRP With PPGL Liner PP / PPH Blocks. HDPE Block. Application In Industries Chlor Alkali Plants. Chemical Plants. Steel Pickling Industries. Pulp And Paper Plants. Bromine & Bromide Plants. Petrochemical And Refineries. Pharmaceutical Industries. Power Plants. Dyes And Intermediate Industries. Pesticides & Fertilizer Plants. Textile And Synthetic Fiber Plants. Desalination Plants. Effluent And Sewage Water Conveyance Lines. Raw water & Potable Water Supply Lines. Sewage & Water Treatment Plants.

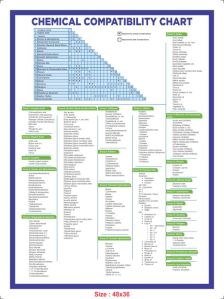

Chemical Compatibility Chart

432 - 864 Per piece

5 piece (MOQ)

This Chemical Compatibility Chart is a shorthand tool for describing the suitability of miniature fluidic and pneumatic component materials for use in contact with various chemicals.