CVD System

175,000 Per Piece

Chemical Vapor Deposition System

1,200,000 Per unit

1 unit (MOQ)

Best Deals from Chemical Vapor Deposition System

Chemical Vapor Deposition System

Get Price Quote

Chemical Vapor Deposition System

Get Price Quote

Chemical vapor deposition (CVD) allows a thin film to be grown on a substrate through molecules and molecular fragments adsorbing and reacting on a surface. This example illustrates the modeling of such a CVD reactor where triethyl-gallium first decomposes, and the reaction products along with arsine (AsH3) adsorb and react on a substrate to form GaAs layers.The CVD system is modeled using momentum, energy, and mass balances including a detailed description of the gas phase and adsorption kinetics. A reduced reaction scheme is compared to the full scheme in the Reaction Engineering interface.

Chemical Vapour Deposition machine

Get Price Quote

Chemical Vapor Deposition System

4,000,000 Per Piece

Metal Chemical Vapor Deposition system

Get Price Quote

Valence Process Equipment offers both production and research-sized MOCVD reactor systems for Group III-Nitride and InGaAl-AsP material systems. We can provide a high degree of customization to suit your specific process requirements. Valence Process Equipment patented, 500-series platform features a non clogging, temperature-controlled showerhead gas injector, and our high symmetry, minimized-volume, non-recirculating pro led reactor, enabling production-level capacities with pilot-level gas and MO usage. Along with high speed wafer carrier rotation, rapid heating capability to 1200C, and high-velocity, uniform- fluid gaps providing efficient heat removal and uniform wall temperatures, the 500-series provides state-of-the-art epitaxial materials properties and uniformities at unbeatable efficiencies. CAPACITY SPECIFICATIONS: – 250- series capacity – 10x2in, 5x3in, 3x4in, 1x6in, 1x8in – 500-series capacity – 72x2in, 20x4in, 7x6in, 4x8in FACILITY SERVICES: – 208 and 380 VAC, 3- Phase Power – Purified N2, H2, and NH3 Gases – Cooling Water Recirculation Loop – Cabinet and Exhaust Ventilation MATERIAL SPECIFICATIONS: – GaN, InGAN, AIGaN, AIN – 2 in., 3 in., 6 in., 8 in. Substrates – Sapphire, Silicon, Silicon Carbide.

Chemical Vapour Deposition Systems

Get Price Quote

QrystalTM is a research grade chemical vapour deposition system, with 12 independent temperature zones, each capable of reaching temperatures upto 1150 °C. It has an inbuilt precision mass flow controller allowing controlled injection of upto 4 gases. A back pressure regulator allows a fixed controlled pressure to be maintained throughout the deposition chamber. Furnace : QBAKE-1100-3 Independent Heating Zones : 12 Maximum Temperature : 1150 °C for transient, 1100 °C for continuous operation Uniform Temperature Zone Length : 200 mm Temperature Uniformity : Better than ±5 °C within a zone Heater Wire Material : Kanthal Process Tube Material : Quartz Process Tube Diameter : ID = 45 mm, OD = 48 mm Embedded Temperature Sensor : K-type Thermocouple Temperature Controller : TCON-12 Sensor Channels : 16 Sensor Type : K-type Thermocouple (or PT100) Independent Control Loops : 12 Control Algorithm : Floating Point P-I-D Temperature Stability : Better than 0.1 °C PID Auto-tune : Yes Heater Drive : 220V, 50 Hz Vacuum System : VAC-10E-2 Pump Type : 2-stage, Rotary Pump Pump Throughput : 15 m3/hour Ultimate Vacuum : 10m-3 mBar Vacuum Sensor : Pirani Gauge and ±15 psi tube pressure sensor mounted at the end of the quartz tube Chamber Isolation : Butterfly Valve Mass Flow Controller : MF02 Number of Channels : 4 Channel 1, 2 : 0-1000 sccm Auxilliary Valves : 2/channel, one in series for true shutoff, one in parallel for flushing Flow Stability : Better than 0.1% of full scale

Chemical Vapor Deposition System

Get Price Quote

1 Piece (MOQ)

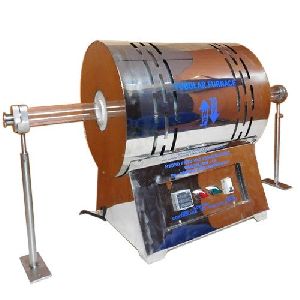

Thermal Cvd System

Get Price Quote

We are offering all types of thermal cvd that are available from us at very nominal rates.

Chemical Vapor Deposition System

Get Price Quote

Chemical Vapor Deposition System, Lab Grown Diamond, Certified Diamond

Plasma Enhanced CVD System

Get Price Quote

Plasma Enhanced CVD System, sputtering system, Lens Holder