Sulphuric Acid Dilution Plant

Get Price Quote

Sulphuric acid is a heavy chemical and finds numerous applications in the industry. It is the product of ‘Contact Process’ and commercially available as 98.5% (ww) H2SO4 or stronger in the form of oleum. However, many of the processes and applications utilizing sulphuric acid require weaker acid than this. As a result, dilution equipment is often necessary in order to meet the requirement for this weaker acid. During dilution, considerable heat is generated depending on the extent of dilution desired. The Integral heat of solution of sulphuric acid is plotted in fig.1. The heat liberated sometimes is sufficient to produce boiling of the acid and so, provision is made for the re-circulation of a portion of cooled dilute acid, thus ensuring working at controlled temperature. From the above it will be clear that intimate mixing and efficient heat transfer form the pre-requisites for sulphuric acid dilution unit to avoid excessive temperature and local heating and uniform product concentration. Process Description Metered quantity of sulphuric acid is introduced to a heat exchanger with re-circulation of water through a pump from the tank containing pre-determinant quantity of water. The turbulence created in the heat exchanger ensures both intimate mixing and efficient heat transfer. When desired strength of acid is reached, the contents of the tank are transferred to storage and fresh batch can be started again.

chemical processing machines

Get Price Quote

Reckoned for our extensive array of products, we efficiently serve our customers from Uttar Pradesh(India). Our organization has all the essential logistic resources and links to ensure on schedule delivery of order(s).

Best Deals from Chemical Plants

Ethyl acetate manufacturing plant

6,500,000 Per piece

Sodium Silicate Plant

725,000 - 760,000 Per piece

1 piece (MOQ)

Chemical Dosing Plant

Get Price Quote

1 Unit (MOQ)

NOx Absorption Plant

Get Price Quote

1 Set (MOQ)

NOx is the generic name given to Nitrogen Oxides. NOx is generated from many processes including nitration process, for both organic and several inorganic compounds (including a few important metals). This is generated due to the partial degradation of Nitric Acid used in the nitration process, as well as to the final treatment of the "spent" acid. These gases are also formed in the nitration of aromatic compounds (toluene, naphtalenes and many of their derivatives), including the production of practically all types of explosives, in the attack of some relevant metals (like copper, bismuth, etc.), in gold & silver refineries and also in the "Nitric Acid Concentration (NAC)" Plants. BVRs NOx Absorption Plants, uses water or caustic solution as per the need. Proper oxidation of NO is completed for the optimum absorption efficiency with minimal energy consumption. When absorbed with water Nitric acid produced can be re-used for re-use in the main process. Both absorption under atmospheric pressure and higher pressures are possible. At lower pressures the acid concentration is low and so is the absorption efficiency with a higher level of emissions. With Pressurised absorption the acid concentration could reach upto 50%w/w and the emission would be considerable lower too.

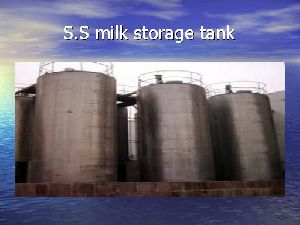

Stainless Steel Storage Tank

Get Price Quote

S.S.Milk / Beverages storage tankIt is made by S .S . 304/316 materials. Capacity : 5000 – 63000 Ltrs.

Stainless Steel Storage Tank

100,000 - 2,500,000 Per piece

1 piece (MOQ)

Stainless Steel Black Storage Tank

500 Per Kilogram

1 Piece (MOQ)

Stainless Steel Storage Tank

100,000 Per Piece

1 Piece (MOQ)

For storing water, the most preferred option is stainless steel storage tanks. NPack Machinery is one of the leading stainless steel storage tank manufacturers and suppliers as we produce round and high-quality tanks that can be easily used for all Industrial purposes. Our stainless steel storage tanks come in different sizes and are properly polished to prevent corrosion. The specially built round shape of the stainless steel storage tank makes it easy to clean and maintain. Thus to obtain a low-maintenance, customised and shiny stainless steel storage tank, head over to Npack Machiner’s official website and order the number of tanks you want. Our process of ordering is simple and we deliver our product all over India.

Sodium Silicate Plant

1,000,000 Per Set

1 Set (MOQ)

Stainless Steel Storage Tank

20,000 - 25,000 Per Piece

1 Piece (MOQ)

Stainless Steel Storage Tank

200,000 Per Piece

1 Piece (MOQ)

Stainless Steel IBC Tank

150,000 - 200,000 Per piece

1 piece (MOQ)

Bitumen Derivatives Plant

Get Price Quote

1 Piece (MOQ)

Stainless Steel Storage Tank

25,000 - 1,000,000 Per piece

1 Piece (MOQ)

Stainless Steel Tank

Get Price Quote

STAINLESS STEEL TANK FOR OZONATION & STORAGE

Stainless Steel Tank

1,000 - 6,000 Per Piece

10 Piece (MOQ)

Stainless Steel Tank

200,000 Per Piece

1 Piece (MOQ)

Oleo Chemicals Plant

35,000,000 Per Piece