Mild Steel Chlorine Injector System

17,500 Per piece

1 piece (MOQ)

Gravity Feed Type Chlorination System

Get Price Quote

10 Piece (MOQ)

Best Deals from Chlorinator

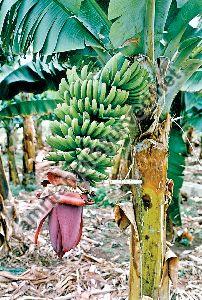

Banana Plant

Get Price Quote

Batch Type Electro Chlorinator

Get Price Quote

1 Piece (MOQ)

Wall Mounted Manual Chlorinator

Get Price Quote

The Industries that benefit Chemicals and Fertilizers, Refineries, Petrochemicals, Power stations, Steel Plants, Cement Plants, Pharmaceuticals, Industries, Pesticide Industries, Food Industries, Textiles, Paper and Pulp Industries,Sugar Plants, Municipalities, Corporations, Townships, Water Boards, Theme Parks, Hotels, Apartment Complexes, etc . We manufacturing wide range of chlorinator and accessories Vacuum feed type gas chlorinator Capacity range from 100 gms /hr to 10 kg/hr . Simple Design, Easy to Operate and Efficient Performance Principle of OperationMotive Water (water at high pressure) passes through the injector to produce vacuum. This vacuum extends upto remote Vacuum Regulator. The chlorine gas received (from Tonners / Cylinders or Chlorine Evaporators) under pressure is reduced to a lower pressure by Pressure Reducing Value and to a constant vacuum at the RVR. The gas under vacuum passes through a Rotameter and Flow Control Valve where the rate of flow can be control by manual or automaticFlow Meter Indicates Directly the flow Chlorine gas in terms of Grams/kilograms per hour. Made of Borosilicate glass and calibrated for 0.1, 0.2, 0.5, 1,2,3,5,6 10, kgs/hr Accuracy is +- 2 TO 4% of indicated flow. Safety Valves - The system is provided with Pressure Relief Valve. Vacuum Relief Valve, Check Valve and Emergency Drain Relief Valve.Flow control valve Manual control valve for manual chlorinator Electical actuator with flow control valve for automatic chlorinator InjectorThere are two type of Injector Fixed-throat Variable – throat types. Variable orifices can be provided along with throttle valve for capacities above 30 Kgs/hr thereby reducing water consumption to a minimum.MOC :- PVC/PVC FRP/ Cast Iron Rubber Lined / Mild Steel Rubberlined AND Stainless steel 304,316Material supplied with system Roller support Yoke Auxiliary container valve Copper tube Manifold valve Manifold (header line ) for one ,two , three , and four tonners. Pressure gauge with isolation valve Pressure reducing valve Remote vacuum regulator Flow meter Flow control valve Pressure relier valve Vacuum relief valve Injector Check valve with emergency drain valve.

Banana Plant

25 Per Piece

1000 LPH SS RO Plant

125,000 - 145,000 Per plant

1 Unit (MOQ)

Compact Electro Chlorinator

Get Price Quote

1 FRP (MOQ)

Banana Plant

30 - 40 Per piece

1000 Plant (MOQ)

Banana Plant

12 - 13 Per Piece

We offer banana plant. With the constant support of our expert team, we are engaged in offering a huge assortment of banana plant. We grow quality banana plant in our own nursery with the help of our experienced farmers and cultivators. They make use of quality fertilizers in growing the plants. Offered in different sizes and packing, these are appreciated for features like high yielding, disease free and economically feasible cash crop with highest returns

Banana Plant

40 - 60 Per Piece

300 Piece (MOQ)

Vacuum Gas Chlorination

Get Price Quote

10 Piece (MOQ)

Chlorination Plant

Get Price Quote

We bring forth highly efficient Chlorination Plant such as water chlorination plant, gaseous chlorination plant and many more. The Water Chlorination Plant that we offer is used for the purification of water. Our Chlorination Plants are made from optimum quality raw materials like PVC and Teflon that enhance their resistance and strength. Our all plants are of durable nature and require low maintenance cost. These plants are very easy to install and operate. In addition to this, we are one of the prime Gaseous Chlorination Plant Manufacturers in India. Details of Components They are mounted on a big panel board ( 4� X 2� ),they consist of Chlorine flow meter, primary filter and safety gauge on its top. Safety loop with nuts at both ends. Besides, there are plastic parts such as secondary filter with NRV on top. Chlorine water mixing chamber and chlorine water solutioniser. In addition, there will be gas bend and water bend joining three PVC chambers and Teflon pipe connecting chlorine cylinder to the Chlorine flow meter. Liquefied chlorine drawn from a steel cylinder gets vaporized at normal room temperature and is led through Teflon connecting tube to the primary filter on the panel board which would arrest all possible cylinder impurities in gas so that they would not abstract the flow of gas through small apertures in the plant. Safety gauge on the primary filter will show pressure only in case of any blockage in any part of the plant. Flow meter will show the flow of chlorine in gms/hour. There will be PVC �U� bend to convey gas from Primary filter to the secondary filter where the gas will be further screened to eliminate all impurities. There will be NRV on top of the secondary filter, hence only chlorine will pass onwards and prevent water to flow back in filter. Water introduced at bottom of the mixing chamber and gas come from top get mixed thoroughly and will flow by a water bend at top into the adjoining solutioniser. The solution will be again mixed thoroughly in the solutioniser and will be further passed gravity to the sump through the PVC outlet and pipe. Usually, one liter of water is required for every five grams of gas for making solution in mixing chamber. Location of the Plant It is desirable to provide the chlorinator in a separate room with very good ventilation. This should be as near as possible to the point of application of chlorine solution into the water supply. Accident prevention legislation requires the floor of the room above ground level with a door leading to a free space. A special floor ventilation ( 2� X 1�) is recommended for better circulation of air. Guarantee Guarantee of the plant for the period of 12 months from the date of supply of the plant, provided the plant is operated strictly as per instructions given by us. Only mechanical defective parts will be replaced free of cost during guarantee period and no free servicing will be done during this period. General The plant�s simplicity of design, reliable performance, unique operating principle, easy operation and highest quality components meet all requirements of today�s advanced standard of sanitary engineering .It is sturdily constructed of acid and chlorine proof, corrosion resistant materials providing long life to the plant. Easily installed and inserts adapt plants for their individual control function making replacement, simple and economical. Its maintenance is exceedingly simple and cheap as replacement of corrosion proof plastic parts is minimized. Problem of gas leakages is automatically solved by provision of lead or PVC washers between large contacts areas at all joints.

Banana Plant

50 Per Piece

1000 Piece (MOQ)

Banana Plant

25 - 30 Per plant

1000 plant (MOQ)

Banana is the oldest and commonest fruit known to the mankind. It is one of the important fruits, and constitutes second largest fruit industry in India. It is nutritious palatable and easily digestible fruit. It is available round the year because of its taste, nutritive and medicinal value. Banana is rich in carbohydrates, minerals such as calcium, potassium, Mg, Na and phosphorous. Other than fresh fruits, it can be consumed as processed in various forms like chips, powder, flakes, etc. Banana pseudostem is chopped and used as cattle feed. Also, the leaves are used as plate. The botanical names of banana are Musa cavendish and Musa paradisiaca, which belongs to the family Musaceae. Banana is the second most important fruit crop of India next to mango. It is favorite fruit of all classes of people.

Chlorination Dosing System

Get Price Quote

1 Piece (MOQ)

Features : Online injection of chemical using Electronic Metering Pump The range are available combine versatility Cost effectiveness Compact size Low maintenance Following range are available with tank & accessories

Electro Chlorinators for Wastewater Treatment

Get Price Quote

1 Piece(s) (MOQ)

Electro- chlorinators also called hypo-chlorite generators. Generated hypochlorite is economic and more beneficial as compared to commercial hypochlorite. Aeolus Chlor is a full range of electro-chlorinators which oxidizes and disinfects waste water and thereby reduces BOD and COD of the effluent. Electro-chlorinators also help in reducing smell and nitrogen in the effluent. If your treated effluent is missing the discharge norms by little, then try Aeolus Electro-Chlorinators for your ETP as an add on and get the perfect solution for your ETP.

Sodium Hypochlorite Generator

5,500 Per Piece

Banana Plant

30 Per Bottle

1000 Bottle (MOQ)

Large Capacity Sea Water Based Electrochlorinator

Get Price Quote

continuous production sea water electrochlorinators are designed for high capacity production of chlorine from seawater. The system contains all the equipment required for the continuous production of 0.1 to 0.2% sodium hypochlorite (refer technical note). These are generally offered as preassembled skid-mounted systems. Typical applications are in cooling water treatment at thermal power plants, water & wastewater treatment, and other disinfection processes where chlorine is required. Here the system uses the salt in seawater and electrolyzes are the same to produce chlorine.