Double Column Bandsaw Machine

850,000 Per Unit

1 piece (MOQ)

We are a coveted organization that is engaged in manufacturing and supplying superior quality Double Column Band Saw Machines. The spare parts and components used for manufacturing are sourced from most trusted and reliable vendors of the market. These Double Column Band Saw Machines are widely acknowledged for their easy operations and minimal maintenance.

CNC Double Column Bandsaw Machines

Get Price Quote

1 Piece (MOQ)

Best Deals from CNC Machining Center

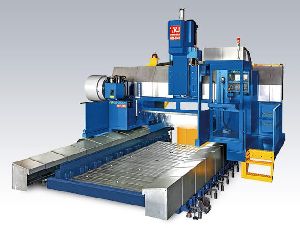

SD Sliding Double Column Machine

Get Price Quote

Features : FANUC 0iMF + 10.4"LCD Spindle and Gear-box cooler Spindle air blast Cutting coolant system Auto lubrication system Rigid tapping Electric cabinet heat exchanger Program end alarm lamp Ethernet/USB/RS232 interface GTP 2G250 H/L gearbox Air/Water cleaning equipment Twin spiral type chip remover Steel belt chip conveyor with cart Working lamp & Tool kit Operator/Maintenance manual X axis steel telescopic cover Y axis JAVARA cover Arm type ATC with tool magazine ATC auto door Foot switch for tool away Leveling screw + foundation bolt X axis rack-pinion-syn. servo control with two linear scales (X 5m) Y axis rack-pinion control with Linear scale (SD(W)-48 & up, GM-45 & up) W axis two linear scales (for SDW) Mobile control room (for SD/SDW) Toggle control panel (for HRP, HDT)

VMC250 Vertical Machining Center

Get Price Quote

1 Piece (MOQ)

U-REX 1325 ATC CNC Machining Center

Get Price Quote

1 Piece (MOQ)

Cnc Vertical Machining Center

Get Price Quote

1 Nos (MOQ)

IRUS make IMV 855, is specially designed for the industries in 3C Component Machining and Die Mold Machining

Used Vertical Machining Center

1,150,000 Per Piece

1 Piece (MOQ)

Horizontal Machining Center

Get Price Quote

Broadway Foundry & Engg Works manufactures Portable Milling and Boring Machine,Horizontal Machining center and CNC Floor Boring Machine

double column fully horizontal metal cutting band saw machine

450,000 - 15,000,000 Per piece

1 piece (MOQ)

Double Column Radial Drilling machine 63mm Cap.

Get Price Quote

Column Drilling Machine

Get Price Quote

60mm All Geared Double Column Radial Drilling Machine

708,000 Per Piece

10000 Piece (MOQ)

Key Features: Main Spindle is made of "EN8" material MT-bore internally grinded Accuracy and run out of 0.01 to 0.04 in main spindle shaft Pinion Shaft is made of "EN8" material Provided 4-8 speeds by accurate balancing Spindle sleeve-grinded Work light[As per requirement] Full size work table with accurate right-angled.[390X300][Surface Grinding is available as per your required] Tapper Roller facility for better sliding of drill head an arm guide Coolant system [As per requirement] Speeds can easily change Nitride Hardened "Ram" All gears are made of alloy steel[Gear Material] and Heat treatment [45 to 55 HRC] hardened & Lapped running in oil bath fitted Ram is accurately grinded and Honing process is done in the bore body containing "Ram" All the gears assemble in the machine are perfectly sized according to requirement All Bearing [NSK [Japan]/NBC/FLT Bearing] Column Design is heavy thickness and grinded as per the sizes required [column size:170mm] Specially spring type balanced spindle travel Manual And Fine feed system options Drilling last capacity : 40mm Heavy Duty structures Strongly ribbed and thick walled base plate having built-in coolant tank Generously Proportional & Well adequately ribbed base plates and column & arm for maximum rigidity and minimum deflection This machine may be capable of drilling & milling & tapping & honing & counter-boring & spot facing & Reaming & boring and other similar utilities.Arm guide surface are precision scraping process Arm length is long [950mm] Wooden case available on demand Optional Accessories: (At Extra Price) Box Table Table stand for drilling cum milling machine Coolant Pump with Fitting Machine Lamp Drill Chuck with key & arbor Drill Sleeve Drill Vice Special T-Bolts Foundation Bolt Service Tool Wooden Box Packing & Forwarding

Cnc Vertical Machining Centre

1,000,000 - 3,000,000 Per piece

1 piece (MOQ)

cnc vmc machine

Get Price Quote

Our presented range of CNC Machine is broadly well-liked in the market for their top performance. These machines are made at our end employing the finest grade raw material and sophisticated techniques. Due to consistent operational and longer service life, these are more..

Double Column Band Saw Machine

Get Price Quote

1 Piece (MOQ)

Double Column Heavy Duty Band Saw Machine

Get Price Quote

Cosmos Vertical Machining Center

Get Price Quote

1 piece (MOQ)

Double Column Radial Drill Machine

Get Price Quote

We offer Double Column Radial Drill Machines that are highly useful for drilling, counter boring, spot facing, reaming, tapping and various other industrial applications. These Geared Double Column Radial Drill Machines are available with robust construction and dimensions to meet clients' demands. The spindle head, radial arm &columns of these machines are clamped by the hydraulic clamping mechanisms. Further, these machines are provided with single-lever to control the forward, reverse & stop braking, speed & feed changing etc. We manufacture these machines keeping into view the ISO guidelines, which make us most reputed Double Coloumn Drilling Machines Supplier in the global market. Features: Robust construction Hydraulic clamping mechanisms With single-lever to control the forward, reverse & stop braking

MEBAeco 500 Double Column Semi-Automatic Bandsaw Machine

1,800,000 Per Unit

1 Unit (MOQ)

Vertical Machining Center

Get Price Quote

Double Column CNC Surface Grinding Machine

Get Price Quote

Our company holds specialization in manufacturing and supplying Double Column Surface Grinder Machine. The Double Column Grinder Machine consist of automatic lubrication system and saddle system design to suit the demands of esteemed customers. This machine features operating systems like L.M Guide, Ball Screw and Servo Motor. These machines are made from premium quality material in variegated technical specifications and capacities to cater to the exact demands of clients. Features: Machine base is a one-piece casting. Machine leveling can be as easy as turning a bolt on the adjustable pad. Internal & External Grinding Capability High Tensile Strength High Performance Wide table with large clearance for job Shapes can be ground with four axis

Column Drilling Machine

Get Price Quote

Column Drilling Machine manufactured by us is the right choice for modern-day production needs. Easy to operate and control, the Column Drilling Machines are designed to handle every type of drilling operation with ease. Available with a set of standard as well as optional accessories, the Column Drilling Machine is offered at market leading rates. Why Our Column Drilling Machine? Rigid construction Impart special finish Suitable for large output Good tool life Standard Accessories Two electric motors, one electric coolant pump Complete with fittings, machine lamb panel board for electrical controls. Optional Accessories Revolving table diameter approx. 4oo mm Tapping attachment Boring attachment Machine vice Machine lamp

CNC 5 Axis Machining Center

650,000 Per Piece

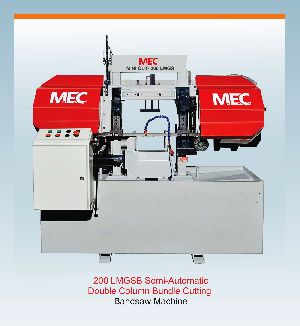

Double Column Semi Automatic Bandsaw Machine

Get Price Quote

200 LMGSB - Semi Automatic Double Column Band Saw Machine with Bundle Cutting option, on Pre-hardened LM guide way for smooth operation and high accuracy specially designed for providing high productivity in low investment. Bundle cutting option provides multiple job cutting in a single cut. Smooth movement of saw frame on LM guides for friction free movement. High Efficiency Power Transmission through helical gear box. Adjustable Dovetail type Heavy duty Movable Blade guide with ball bearing. Automatic switch-off of the blade after finishing the cut. Bundle Cutting Arrangement. Automatic heights stop for saw frame to save idle time. Hydraulic Power Pack with easy maintenance. Double Acting Hydraulic Cylinder for Main vice Clamping & De-clamping. Infinitely variable Feed Control Valve for Setting the Cutting feed. Electrical control panel with high quality switchgears.

MDH Series Horizontal Machining Centre

Get Price Quote

The MDH Series is the ideal machining center for producing box-type and irregular work pieces for automobile, shipbuilding, engine and general engineering industries. The machine is a high-performance, high-reliability and high-precision product characterized by a compact configuration and rapid response rates. The spindle design makes it particularly suitable for heavy power cutting while the excellent ball screw & spindle cooling system provide superb capability for flexible manufacturing. High-speed High-power Spindle The high performance, programmable two speed integrated electric spindle motor means that the MDH is not only capable of high-speed, high-power cutting, but also provides excellent low-speed high-torque cutting. Compact Configuration and Unrivalled Rigidity The machining center is constructed from thick wall box castings providing exceptionally high rigidity. The extra thick castings of the base and column Improve rigidity, and control thermal deformation to a minimum thus keeping exceptionally high precision over extended periods. The unique configuration of the MDH horizontal machining center in which the X-axis moves left and right and Z-axis moves the table forward and backward makes the machine work more effectively. The compact configuration also means that the machine takes up 30% less space than formermachining centers and makes the machine particularly suitable for machining automobile engine cylinder body, large steel components, casting and Aluminum components. High-speed ATC The fully mechanical, cam-operated, ATC system ensure high-speed accurate tool changing with high durability. The cam provides a variable-speed function so that heavy tools are changed smoothly while the single-motor system ensure complete synchronization of the tool clamp/unclamp operation during high-speed ATC operation. Combined with a high-speed automatic shutter, the ATC completes a tool-to-tool change in 2/2.5 seconds, while the cassette-pot magazine design permits flexibility for tool capacity expansion, and boasts a top-class tool weight capacity of 25kg. High-speed APC The direct-drive APC mechanism is designed to lift and rotate only, thus achieving an APC time of only 12.5 seconds as well as accurate table changing operation. A multiple APC system (8 or 10 pallets) can be provided to add flexibility in future system expansion and line configuration. Maximum table loading is 2000 kg.

BDC-650 M Semi Automatic Double Column Band Saw Machine

900,000 Per Piece

1 Piece(s) (MOQ)

cnc vmc machine

Get Price Quote

Technical Specification of CNC Double Column Vertical Machining Center Standard Features AC Spindle Drive AC SERVO Axis Drive L.M. Roller type Guideways (X & Y) Auto & Manual Collent Centralized & Programmer Lubrication Electricals with Quality Device & Work Light CNC SIEMENS SINUMERIK 828D Optional Accessories Laser Calibrated axis for high precise positing accuracy & Repeatibility Chip Convyor Linear Glass Scale for Axes Collent Through Spindel ATC (32/40/60/90) Extra Day Light Oil Mist Collector System Auto Indexing Head (Horizontal) Manual Horizontal Head Rotary Table Tool Probe Job Probe Gear-Box (4000rpm) Full Cover Enclosures

CNC Vertical Machining Centre (ARV 700PC)

Get Price Quote

The ARV 700PC is an advanced CNC Vertical Machining Centre made for delivering high output with low maintenance costs. It is a 3 axes machine that gives consistent performance. It is best suited for fabricating machine components that require a high degree of precision. It comes with a versatile set of 20 tools ATC and a BT-40 spindle taper. The fast auto tool-changer of this CNC Turning Machine reduces the idle time and thus increasing production. The 10000 RPM customized spindle gives a higher metal removal rate. Fanuc 0iMF + CNC Turning Machine Controller in the ARV 700PC ensures a better performance of the machine under all conditions. This high powered device is perfect for cutting hard metals and metal alloys. Its faster chip removal rate and superior coolant delivery systems makes it ideal for difficult jobs that require high levels of accuracy. Its twin pallet changer (Servo, optional) increases the productivity of the machine making it optimal for cutting steel, cast Iron and Aluminium. The machine is perfect for the automobile industry and the aerospace industry. It can also be used to manufacture intricate parts used in certain home appliances and orthopedic implants. This CNC milling machine will lend technical superiority to your workshop through its highly accurate milling, boring and drilling actions.

HDT Double Column Machine

Get Price Quote

Use of finest raw material helps us in bringing forth exceptional products. Due to this very fact, we make use of only quality raw materials procured from trusted sources. Feel free to place orders with us, we ensure timely and safe deliveries of the same. Details : Operator/Maintenance manual. Spindle and Gear-box cooler. Ethernet/USB/RS232 interface. GTP 2G250 H/L gearbox. Air/Water cleaning equipment

Feeler FV Machine

1,300,000 Per Piece

1 Piece(s) (MOQ)