Steam Coal Ashes

1,500 Per Ton

30 Ton (MOQ)

Low Ash Coal

Get Price Quote

550000 Metric Ton (MOQ)

Best Deals from Coal Ashes

Coal Ash

Get Price Quote

16 Metric Ton (MOQ)

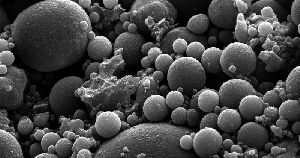

Coal ash, also referred to as coal combustion residuals or ccrs, is produced primarily from the burning of coal in coal-fired power plants. Coal ash includes a number of by-products produced from burning coal, including: fly ash, a very fine, powdery material composed mostly of silica made from the burning of finely ground coal in a boiler. Bottom ash, a coarse, angular ash particle that is too large to be carried up into the smoke stacks so it forms in the bottom of the coal furnace. Boiler slag, molten bottom ash from slag tap and cyclone type furnaces that turns into pellets that have a smooth glassy appearance after it is cooled with water. Flue gas desulfurization material, a material leftover from the process of reducing sulfur dioxide emissions from a coal-fired boiler that can be a wet sludge consisting of calcium sulfite or calcium sulfate or a dry powered material that is a mixture of sulfites and sulfates coal ash is disposed of or used in different ways depending on: the type of by-product, the processes at the plant and the regulations the power plant has to follow.

Fly Ash/ Coal Ash

Get Price Quote

Fly ash is produced from the burning of pulverized coal in a coal-fired boiler. It is a fine-grained, powdery particulate material that is carried off in the flue gas and normally collected from the flue gas by means of electrostatic precipitators , baghouses, or mechanical collection devices such as cyclones. Fly ash is commonly used in production of concrete. It is applied as a supplementary cementing material. Initially the idea was to use fly ash for economical reasons – on one hand to utilize fly ash which is an industrial by product, on the other to reduce the amount of costly cement. However, it appears that application of fly ash in concrete has a lot of benefits, mainly by reduction of unwanted hydration heat. Cement can be replaced with fly ash in concrete. It reacts (Si) with Ca(OH)2 and produces more CSH gel which contributes to strength. With reduced cement, hydration heat will be reduced and hence there is strength gain. Uses: The most common use of fly ash is as a partial replacement for Portland cement used in producing concrete. Replacement rates normally run between 20% to 30%, but can be higher. Fly ash produced by coal-fired power plants provides an excellent prime material used in blended cement, mosaic tiles, and hollow blocks among others. Fly ash can be an expensive replacement for Portland cement in concrete although using it improves strength, segregation and ease of pumping concrete. The rate of substitution typically specified is 1 to 1 and a half pounds of fly ash to 1 pound of cement. Fly ash can be used as prime material in blocks, paving or bricks; however, one of the most important applications is PCC pavement. PCC pavements use a large amount of concrete and substituting fly ash provides significant economic benefits. Fly ash has also been used for paving roads and as embankment and mine fills, and its gaining acceptance by the government , specifically the Highway Administration. Fly ash reacts as a pozzolan with the lime in cement as it hydrates, creating more of the durable binder that holds concrete together. As a result concrete made with fly ash is stronger and more durable than traditional concrete made exclusively with Portland cement.Benefits : Fly ash can be a cost-effective substitute for Portland cement. In addition, fly ash could be recognized as an environmentally friendly product because it is a byproduct and has low embodied energy. It is also available in 2 colors, and coloring agents can be added at the job site. In addition, fly ash also requires less water than Portland cement and it is easier to use in cold weather. Other benefits include : Can withstand harsher service environments Less susceptible to chemical attacks and mitigates the negative impact of deleterious aggregates. Improved flowability, reduced hydration temperatures and delayed setting time of fly ash concrete Longer service life Used to mitigate a problem called alkali silica reaction which occurs when concrete deteriorates early due to issues with aggregate quality. Costs less Has positive environmental impacts, as it conserves landfill space, reduces energy and water consumption, and helps reduce greenhouse gases Produces various set times Cold weather resistance Higher strength gains, depending on its use. Can substitute Portland cement Considered a non-shrink material Produces denser concrete and a smoother surface with sharper detail Great workability Reduces crack problems, permeability and bleeding Reduces heat of hydration Produces lower water/cement ratio for similar slumps when compared to no fly ash mixes. Reduces CO2 emissions. Types of fly ash : There are different types of fly ash , depending on its chemical properties, including Class F and Class C , generated by burning black coal and brown coal respectively. Class F and Class C are being utilized in making building materials such as concrete, lightweight aggregate, bricks etc. Also fly ash is used as a material for road construction and earth filled dam construction. Class F fly ash is available in larger quantities , which is generally low in lime , less than 15%, and contains greater combination of silica , alumina and iron(more than 70%) compared to Class C fly ash. Class F is a solution to a wide range of summer concreting problems and it is often recommended for using where concrete may be exposed to sulphate ions in soil and ground water. Class C fly ash normally comes from coal which produces an ash with higher lime content, generally more than 15%, often as high as 30%. Also, high Calcium Oxide(CaO) gives Class C unique self hardening characteristics. Class C is mostly used in situations where higher early strengths are important.

Bottom Ash

Get Price Quote

1000 Metric Ton (MOQ)

Bottom Ash

Get Price Quote

coal fly ash

Get Price Quote

We have a sound payment policy. Following it, we maintain transparency and only use methods that are safe, secure, and legal. Our clients can choose out of number of options as per convenience. We own a capacious and well structured warehousing unit wherein we store the entire lot away from diverse damaging factors such as moisture, rain, sunlight and various others.

Coal Ash

3 - 5 Per kilogram

10 Tons (MOQ)

Coal Ash

Get Price Quote

CEMGUARD® Fly Ash is a pozzolanic material, captured in electro-static precipitators as a by-product from coal-fired thermal power stations. It consists of small, hard and spherical particles rich in silica (glass) and alumina, with pozzolanic properties. It complements Portland cement upon hydration by reacting with free lime (calcium hydroxide) to form an additional durable binder, namely calcium silicate hydrate. The spherical particles also have a ‘ball-bearing’ effect, which allows concrete to be produced using less water. CEMGUARD® Fly Ash is subject to processing quality control to regulate its fineness (particle size and distribution, shape and glass content) and unburnt carbon (loss-on-ignition), thus giving quality-assured material which is consistent, predictable and suitable for varied applications. We are working towards CE Marking for CEMGUARD® Fly Ash. CEMGUARD® Fly Ash is mainly used as a partial replacement of cement in concrete, and has unique properties that benefit both fresh and hardened concrete. Its key advantages include reduced heat of hydration, improved workability, enhanced durability and longer setting time. It can be effectively used where aggregates have poor grading and shape, resulting in bleeding and segregation. It is also suited for mass concrete applications, and in hot and aggressive environments where early-age thermal cracking and durability are major concerns. General replacement of cement with CEMGUARD® Fly Ash in concrete can be 15-35% by weight for normal structures. However, for special structures such as dams, the replacement levels can increase up to 70%. The service life of structures using CEMGUARD® Fly Ash is enhanced by more than 100% on account of superior durability of concrete. Fly Ash use in concrete qualifies for credit under the U.S. Green Building Council's popular LEED® rating system for sustainable construction.

coal fly ash

Get Price Quote

50-100 Metric Ton (MOQ)

coal fly ash

Get Price Quote

Backed by rich industry experience, we are engaged in manufacturing and supplying a commendable range ofCoal Fly Ash. Coal ash is formed when coal is burned in boilers that generate steam for power generation and industrial applications. Fly Ash is cement like fine grey powder consisting of the finely divided residue resulting from the combustion of Coal at coal-fired power station. It has pozzolanic properties and reacts chemically with calcium hydroxide at ordinary temperature to form insoluble compounds possessing cementitious properties. Technical Features of Coal Fly Ash In addition to economic and ecological benefits, the use of Fly Ash in concrete improves its workability, reduces segregation, bleeding, heat evolution and permeability, strength, inhibits alkali aggregate reaction and enhances sulphate resistance. The percentage of Fly Ash is usually used as part of the cementitious components in concrete normally from 15 to 25% and can even go up to 30-35% in some applications. Packaging of Coal Fly Ash Fly Ash is offered 1.3 -1.4 MT quality jumbo bags with liner. The jumbo bags conform to GB/T 10454 and EN ISO 21898 standard, with UV proof function and anti- character.

Coal Ash

Get Price Quote

Coal ash is the generic term referring to several very distinct materials produced when we combust coal to produce electricity. Coal ash offers our society extraordinary environmental and economic benefits without harm to public health and safety when properly managed.Our industry refers to these materials as “coal combustion products” or “CCPs” to emphasize that they have significant commercial value. A multibillion-dollar industry has arisen over the past 50-plus years around the use of these materials, which include fly ash, bottom ash, boiler slag, and various forms of flue gas emission control/ desulfurization materials. Each of these varies by coal source and composition, combustion technologies, emissions controls technologies, and other factors.

Coal Ash

Get Price Quote

HUGE investment lined up in coal-fired power plants in Gujarat will proper coal imports by almost 300% over next four to five years. If the proposed investments in imported coal-field power units come through, ports in Gujarat will import over 50-55 million tones of coal annually, up from current imports of less than a million tones. Coal consumption by captive power units in coastal areas will also increase which should further boost demand in the state.

Coal Ash

Get Price Quote

Coal Ash, Construction Material, Construction Material, Fly Ash, Iron Slag

coal fly ash

Get Price Quote

coal fly ash, Saw Dust

coal fly ash

Get Price Quote

coal fly ash, minerals ore, Coal, Coal Fines, iron fines, Gypsum

Wet Coal Ash

Get Price Quote

Wet Coal Ash, Stainless Steel Scrap, Used Engine Oil, mustard seed oil cake

Bottom Ash

30 Per Ton

We can Supply Good quality of Flyash and bottom ash in Mass -6000T/day. Very near to Port Just 20km. Export facility also avilable. Bags & bulker loading facility available. Biggest power producer in india. Contact us for more details.

Coal Dust Low Ash

Get Price Quote

Blend of carefully selected lustrous carbon carrying carbonaceous additives. It is an indispensable additive for any foundry.

Coal Ashes

30 - 120 Per kg

Coal Ash

Get Price Quote

Coal Ash, Concrete Bricks, Fly Ash, Masonry Cement, Lime

Bottom Ash

Get Price Quote

50 Metric Ton (MOQ)

Bottom Ash with proper dispatch system available at our Sembcorp Gayatri Power Plant which can dispatched through Open Trucks

Coal Ash

Get Price Quote

Coal Ash, Dry Fly Ash, Copper Slag, Gypsum and Gypsum Products, Lime, Coal

coal fired fly ash

Get Price Quote

coal fired fly ash

coal fly ash

Get Price Quote

coal fly ash, Fly Ash

Coal Ash

Get Price Quote

Coal Ash, Fly Ash

Coal Ash

Get Price Quote

Coal Ash, Bio Coal, Lignite Powder

coal low ash

Get Price Quote

coal low ash, hard coal

Coal Ash

Get Price Quote

Coal Ash, lignite

Coal Ash

Get Price Quote

Coal Ash, Coal, Tippers, Steam Coal, Construction Equipments, Fly Ash