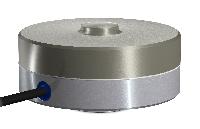

Rocker Column Compression Type Load cell

Get Price Quote

Key Features : Pre-Calibrated technology (Collaboration with European technology) No Need to Make Calibration (Just Plug & Weighing) Strong Digital Signal provide accurate weighing Profitability to Highest Weighing Accuracy Nickel Plated Tool Alloys Steel True Hermetically Sealing Inbuilt Lightning Protection - Electronic Gas Discharge Tubes Inbuilt Temp. Protection & Surge Protection No Corner Error No Analogue to Digital Converter Predictive diagnostics simplify troubleshooting Two Years Warranty in Eagle Make Load Cells Technical Parameters : Rated Load (E-Max) - 20, 30, 34.5, 40, 50, 60 t Rated Output (mV/V) - 2.00 ± 0.01 Non-linearity - ±0.02% F.S Hysteresis - ±0.02% F.S Repeatability - ± 0.01% to ± 0.02% F.S Creep (30 minutes) - ± 0.02% F.S Zero Balance - ± 1.00% F.S Temperature Effect on Zero - ±0.02% F.S Temperature Effect on Output - ±0.02% F.S Protection Class (IP) - IP68 Communication BPS - 9600/19200 Communication Mode - RS 485 Insulation Resistance (O) - 3000M Excitation Voltage - 7 to 15V DC Compensated Temperature Range - (-10oC to +50oC) Operation Temperature Range - (-20oC to +60oC) Safe Overload - 150% F.S Ultimate Safe Overload - 200% OF R.C Cable - F4 x 16m

Flintec Rc3 Compression Load Cell - 30 Ton

24,499 - 24,500 Per UNIT

1 Unit (MOQ)

Best Deals from Compression Load Cell

Double Ended Compression Type Load Cell

8,000 Per Piece

1 Piece (MOQ)

compression type load cell

12,000 - 16,000 Per Piece

1 Piece (MOQ)

Compression Load Cell

Get Price Quote

Truck Scale. Tank Weighing. Hopper Weighing. Compressive force Testing. Industrial Automation.

Compression Load Cell

22,000 - 45,000 Per Piece

1 Piece(s) (MOQ)

Compression Load Cell

Get Price Quote

Specifications: Features: Low profile design Rugged structure Resistant to eccentric loading

Heavy Duty Compression Load Cell

7,500 - 55,000 Per Piece

-1 Piece (MOQ)

10 Ton Compression Load Cell

40,000 Per Piece

1 Piece (MOQ)

Compression Load Cell

Get Price Quote

We are offering single column type load cell asc2 application : track weighbridge.

Compression Load Cell

21,000 Per Piece

1 Piece (MOQ)

Load Cell Pin

Get Price Quote

Reckoned for our extensive array of products, we efficiently serve our customers from Surat(India). We frequently keep a check on the storage space to ensure that it is well-maintained by the experts. We have installed the latest machines and leading technologies to save products from spoiling.

Compression Load Cell

Get Price Quote

Backed by the profound industry experience, we have been able to offer Compression Load Cells. The offered load cells are widely used for the purpose of tank & hopper weighing. These are stringently examined by our team of quality analyzers on varied parameters to ensure their flawlessness. Our load cells can easily be availed by the patrons at competitive prices from us. Moreover, our products are highly acknowledged for their attributes like longer service life and minimal maintenance.

Analog Compression Load Cell

18,500 Per Piece

1 Piece (MOQ)

Compression Load Cell

15,000 Per Piece

1 Piece (MOQ)

CMP compression load cell

Get Price Quote

The Compression load cell Model CMP is about Monolith Construction and is made from high nickel alloy steel. The load cell is suitable for robust design & due to its unique construction in design, this allows angular loading without affecting the accuracy. The load cell is sealed to the IP68 standard. The unique mounting cups combined with optimal radius of Loadcell provides this rocker assembly Load cell

compression load cells

Get Price Quote

It is a high capacity truck scale and silo load cell which is supplied complete with its own unique rocker mounting components. Suitable for all heavy duty weighing applications the Model 120 gives the user high accuracy and low installation cost. The Model 120 has a stainless steel housing to protect against corrosion. The alloy steel compression element is nickel-plated, and the rocker mounting accessories are zinc-plated alloy steel. The two additional sense wires feed back the voltage reaching the load cell. Complete compensation of change in lead resistance due to temperature change and/or cable extension, is achieved by feeding this voltage into the appropriate electronics

compression type load cell

Get Price Quote

Ball and Cup Load cells surpass Its Competitors in Terms Of Resistance against Side Forces. It Is a Fact That the Major Reason behind Load cell Manufacturing Is the Horizontal Side Forces Created by the Vehicles during Brakes and Sudden Start-Ups. That Is why, Scales with Column Type Load cells require Construction Absorbing Side Forces. However, Such Construction As Rocker Supports, Tensions Rods, Buffers, Etc Need Maintenance And Have An Adverse Impact on Weighing Accuracy. applications, the double ended shear beam offers a number of advantages over other designs. Units like the one shown opposite have built-in jacking bolts which can be used to support the weighing structure during installation thus allowing the live load cells to be fitted just prior to commissioning, avoiding damage. The load cell is designed to rock on its mounting base to accommodate misalignment in mounting surfaces whilst still being retained. The mounting arrangement also permits limited movement to allow for thermal expansion and contraction as well as lift off protection. Double-Ended Shear Beam Type CUP & BALL TYPE concept in load cell design provides the following advantages over the conventional compression type load cells.

Compression Load Cell

6,000 - 35,000 Per PIECE

1 Piece (MOQ)

Main features:Alloy steel & stainless structure; bellows hermetically sealed by laser, nickel plated, waterproof and anti-corrosion, suitable for multiform environments; suitable for electronic platform scales, hopper scales, and other electronic weighing devies.

compression type load cell

Get Price Quote

Compression Type Load Cell Application: Weighbridges, hoppers, tanks and silos Stainless steel construction High input resistance Features: Capacity: 7.5MT to 45MT Complete environmental protection IP-68 class with complete hermetic sealing Standardized output (3.0 + 0.25 %) available on request Calibration in mVVΩ Sensor Technology: Strain Gauge