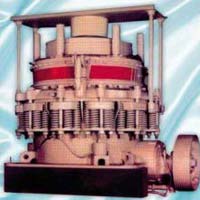

Cone Crusher

Get Price Quote

1 piece (MOQ)

120TPH Mobile G.S.B. Crusher Plant

13,600,000 - 16,000,000 Per Set

Best Deals from Cone Crusher

Automatic Cone Crusher Machine

400,000 - 6,200,000 Per piece

1 piece (MOQ)

Cone Crusher

Get Price Quote

We are the main supplier of this product.

Cone Crusher

6,000,000 Per Set

Being a client centric firm, we are affianced in providing Cone Crusher.Other details: A SS Engineers Cone Crusher is one of the main types of secondary crushers in a mine or ore processing plant SS Engineers cone crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Our product cone crushers can be used for secondary crushing The company product is easy maintenance with hydraulics adjustment and lifting Excellent product distribution and fineness Low operation costs and easy wear parts replacement Easy maintenance with hydraulics adjustment & lifting High manganese mantle & concave Strong counter shaft design with bevel gear & pinion Strong body with heat treatment Hydraulic Clearing Hydraulic Adjustment Heavy Duty Design High Productivity Long Life Standard Replacement Parts

Cone Crusher

2,500,000 Per Set

For Secondary / Tertiary stage crushing. Automatic / Semi automatic operating system. with hydraulic tramp release system. Machine Capacity range from 100 TPH to 300 TPH

Symons Cone Crusher

Get Price Quote

Material that has been pre-crushed enters into the top of the cone crusher; the material is then squeezed and crushed again between the mantle and concave. A cone crusher is almost the same as a gyratory crusher, it has less of a slope in the crushing chamber and is more parallel between crushing zones. A cone crusher breaks rock by squeezing the rock between an rotating spindle. As rock goes in the top, it becomes wedged between the mantle and the concave. Large chunks of ore are broken, and fall to a lower position where they are broken again. This process repeats until the material is small enough to exit from the bottom of the crusher. Modular; non-welded construction design. Hence it has no welding stress and thus frame has long service life time. Adjustment of CSS setting is quick and safe due to fully hydraulic twin wedges setting adjustment system. Replacement of existing Jaw Crusher as capacity is larger and size is compact, so modifications to the existing foundation are rarely required.

30mm Cone Crusher Spring

3,560 Per Piece

2 Piece (MOQ)

Cone Crusher

Get Price Quote

A cone crusher is a mechanical machinery used in many developing countries like Use of cone crusher in the industry has proven to help increase the productivity and quality level. This is the main reason why use of these cone crushers is rapidly increasing in most of the developing countries including India.

H TYPE CONE CRUSHER

Get Price Quote

Our H type cone crushers are of advanced design with high capacity in relation to size, are used in the secondary & tertiary applications. They have high reduction efficiency and give very good product shape. Our H-Type cone crushers are available in 18 variants of capacities from 50 to 400TPH. A combination of chamber range, and high motor power give the crusher a wide range of application combinations to suit different installations. FEATURES AND BENEFITS: Excellent versatility due to a wide range of chambers with different feed acceptance. Full control of the process. Easy to maintain. Extremely reliable H-Type cone crushers are suitable for a wide range of applications, including quarrying & mining . End products are final aggregates for concrete and road projects, Cone crusher series combine extremely high performance with low total cost.

Hpc Cone Crusher

Get Price Quote

Base on the latest technology and decades of years’ producing experience, SBM designed the HPC series cone crusher. It has excellent crushing efficiency and good hydraulic control system. Now the HPC series cone crusher has wide application in secondary crushing of many kinds of mining and rock, etc. Features Large reduction ratio, high production efficiency; Less consumption of wearing parts, low operating costs; Pyramid broken, perfect of product shape; Hydraulic protection and hydraulic pressure cavity clear high degree of automation to reduce downtime; Application HPC series cone crusher is applied to cement mill, mining, building construction, road &bridge construction, railway construction and metallurgy and some other industries. Materials like iron ore, granite, limestone, quartzite, sandstone, cobblestone and some others are easily crushed by cone crusher.

SP220 Cone Crushing Machine

4,500,000 - 8,500,000 Per Piece

1 Piece (MOQ)

PYT Series Cone Crusher

Get Price Quote

Based on latest technology, the PYT Series Cone Crusher has optimized design and long functional life. NHI China has showcased its presence among the leading Supplier of PYT Series Cone Crusher in China. NHI China offer 14 models and 5 types of PYT Series Cone Crusher. These PYT Series Cone Crushers can perform secondary crushing and fine crushing on all kinds of mine ore or rock of different hardness.

Py Cone Crusher

Get Price Quote

Adopting technology from the world, PY Series spring cone crusher has an excellent performance in secondary crushing and tertiary crushing process and it has become the ideal cone crusher for small capacity crushing plants of mineral ore processing industry and rocks processing industry. Features High productivity; high quality. Less machine stop time. Easy maintenance and low cost. Unique crushing ability in primary, secondary and tertiary crushing.

Cone Crusher

5,500,000 - 9,500,000 Per Set

1 Set (MOQ)

Cone Crusher 150 TPH/200 TPH/250 TPH/300 TPH/400 TPH

Cone Crusher

Get Price Quote

Cone Crusher

Get Price Quote

Comparing with other kinds of crushers, CS Series spring cone crusher is quite excellent in hard material crushing and the final product has good sharp. The innovations like stable lubrication system and excellent sealing system evidently reduce the production cost, helping you to achieve the highest level of profitability.