Continuous Pickling Lines

Get Price Quote

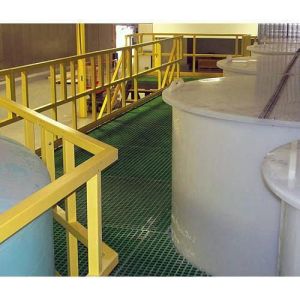

GPPL has introduced innovative engineering design and development in manufacturing of thermoplastic equipments. Introduction of radius at corner using full sheet of thermoplastics for pickling tank. Weld less radius provides sound mechanical strength. GPPL pickling tanks are made from chemical resistant thermoplastics and are welded with butt fusion and gas extrusion technology(imported from Europe) and they are welded as per recommendation and standard DVS 2207 laid down by German Welding Society. To fulfill the varying needs of the clients, we manufactured the Continuous Pickling Lines using superior-grade raw material procured from the reliable and well-established vendors of the market. It is highly reliable for a longer service life with assurance of excellent performance. Under the supervision of our highly adroit quality auditors, we tested this product on different parameters like strength, dimensional stability, corrosion resistance and design. Applications Pickling line for hot dip galvanizing. Tube & Pipe Pickling Plant ( Stainless Steel & Non-ferrous). Wire Planting Line (Batch/Continuous). Strip/Coil Pickling Line. Electroplating and Anodizing tanks. Pre & Post Treatment Tanks. Storage & Holding Tanks. Degreasing Lines. Passivation Lines. Lead- Acid Battery Manufacturing Unit. Quality Testing Welding quality is confirmed by 3 point bend test, specimen seam is tensile and impact resistance property. Leakage testing is carried out prior to dispatch by hydro, vacuum and spark test. Test carried out as per DVS 207 guidelines of German Welding Society. Specifications Planning and construction of tank system with fume exhaust system, Effluent treatment plant. Robust design of tank made out of industrial thermoplastic. Environment friendly fume extraction system, avoiding corrosion of surrounding steel construction, cranes and roof structure. Plastic tanks available in flat pack modules (reduced volume). Tank made from industrial thermoplastic and welded with state-of-the-art hot gas extrusion welding process and stress relived. Modules assembled and welded at site for easy transportation. 100% leak proof welding. Fume free work place. Corrosion free atmosphere. Tanks are available upto 24 meter length. Polypropylene tanks are suitable for mixture of hydrofluoric acid, nitric acid also suitable for HCL acid.

continuous pickling line

Get Price Quote

Continuous Pickling is a production that the steel strip is pulled continuously through the acid tank and rinsing tank. The line is characteristic with high efficiency and output, and low electricity consumption. The annual output of the line is 600000~1800000 tons.

Best Deals from Continuous Pickling Line

Ms Continuous Pickling Line

1,000,000 Per Unit

Mild Steel Continuous Pickling Line

Get Price Quote

Continuous Pickling Lines

45,000,000 Per Unit

Continuous Pickling Lines

Get Price Quote

continuous pickling line

1,000,000 Per Number

Wire Pickling Plant

Get Price Quote

continuous pickling line

Get Price Quote

continuous pickling line

Get Price Quote

continuous pickling line, Cr Slitting Line, Hr Slitting Line, Slitting Line

continuous pickling line

Get Price Quote

continuous pickling line, Zinc Flake Coating, geomet coating plant

Continuous Pickling Lines

Get Price Quote

Continuous Pickling Lines, Tension leveling lines, Color Coating Lines

continuous pickling line

Get Price Quote

continuous pickling line, rewinding line, Auto Springs, Screw Jack

continuous pickling line

Get Price Quote

continuous pickling line, hot rolling machine, hot rolling mills

continuous pickling line

Get Price Quote

continuous pickling line, galvanizing furnace, Ovens Incineration System

Turbo-Tunnel Continuous Pickling Line

Get Price Quote

Turbo-Tunnel Continuous Pickling Line, Tension Levelling Lines

Continuous Pickling Lines

Get Price Quote

Continuous Pickling Lines, Cold Rolling Mill, Tension Levelling Lines