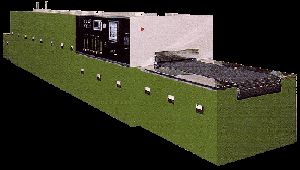

Conveyor Mesh Belt Furnace

Get Price Quote

Electric Conveyor mesh belt type furnaces are used for continuous heating purpose of large quantities of goods. Conveyor belt continuously rotate through the furnace electrically which poses the temperature (250°C to 1200 ºC). Material to be heated is kept at one end on belt which passes through the furnace.Key Features Continuous heating purpose of large quantities of goods. Material to be heated is kept on Conveyor belt which continuously rotate through the furnace. Maximum temperature (ambient to 1150°C). The furnace is designed to operate with hydrogen atmosphere, cracked ammonia atmosphere, nitrogen and argon atmosphere. Specially designed corrugated muffles (metallic) are used to withstand thermal expansion for certain processes. Metallic muffles may be of stainless steel or high nickel and chromium based alloys. Energy efficient, Improve productivity and excellent repeatable heat treatment. A variable speed drive unit with widely adjustable belt speeds allows the treatment of different thicknesses of materials and grades with varying temperature-time requirements.

Conveyor Spring Tempering Furnace

750,000 Per Piece

in order to keep pace with the requirement of the clients we manufacturer and supply a wide array of spring tempering furnaces. the range we offers consist of continuous spring tempering furnaces that provide accurate function and optimul performance. owing to the years of experience, we manufacturer and supply of quality gamut of continuous spring tempering furnaces. these product are reckoned for its durability and strength condition: new quality: good usage: industrial speciality: long functional life advantage; easy to operate durability: long life feature: affordable price, high performance

Best Deals from Conveyor Furnace

Industrial Conveyor Furnace

Get Price Quote

1 Piece (MOQ)

This perfectly designed industrial conveyorised furnaces are appropriate for heat treatment of bulk jobs on unremitting basis like forged steel parts, washers, sockets and bearings. Conveyors are mesh belt type or slat type or chain-strap type. Momentum of conveyor can change through dc control drives. These conveyor furnaces contain the following features: multi-temperature zones depending on application are available automated temperature control on programming and recording the conveyor furnaces have sturdy steel body with high grade thermal insulation. Gas tight muffle inside heating chamber for circulation of protective gas can be offered for handling under defensive atmosphere such as bright hardening, sintering brazing and annealing.

conveyor furnace

Get Price Quote

Our conveyor furnaces are used for heat treating products where high volume production and low cost are favored. These furnaces are designed according to the customers’ process requirements and cycling time such as drying, preheating, curing etc. Uniform heating is achieved by mounting heating elements on support tubes, which facilitate high free radiation and excellent service life of the heater. The products are moved within the chamber on a mesh belt, supported by a belt drive made of rubber coated belt drums.

Conveyor Type Furnace

1,300,000 Per Piece

1 Piece(s) (MOQ)

We are main supplier of this product.

safed electric conveyor furnace

100,000 Per Piece

conveyor furnace

Get Price Quote

We manufacture and supply all types of industrial conveyor furnaces, continuous heat treatment plant,heat treatment furnaces plant,annealing furnaces,rotary furnaces,hardening furnaces,tempering furnaces,stress relieving furnaces, normalizing furnaces,gas carburizing furnaces,spares and allied equipment.

Optical Glass Molding Conveyor Furnace

Get Price Quote

We are offering optical glass molding conveyor furnace. suitable for manufacture of optical by-focal blank temperature op to 800 c prodution 100prh lxbxh= 25ftx2ftx1.5ft starting load in first hour 7kw running load 3 to 4 kw

Conveyor Annealing Furnace

Get Price Quote

> Electric, Diesel Fired & Gas Fired> Temperature 0 - 800oC> Digital Temperature Control/Variable Speed> Used in - Brass / Copper Annealing, all kind of Annealing purpose > Available in All sizes As Per Customer Requirement

Conveyor Type Washing Machine Furnace

Get Price Quote

We are one of the prominent Manufacturers, Exporters and Suppliers of Conveyor Type Washing Machine Furnace. Made in accordance with industrial norms, our entire range is quality assured, tested and reliable. It is excellent for washing the oily materials that are released due to metal treatments. Buyers can purchase Conveyor Type Washing Machine Furnaces from us as per requirement. We offer them in varied specifications and provide customized solutions as well. Buyers can obtain Conveyor Type Washing Machine Furnaces from us in single and double stage. Specifications : Single stage : Hot water spraying through jet Double Stage : Hot water with the Blower

Industrial Conveyor Furnace

730,000 Per Piece

1 Piece (MOQ)

conveyor furnaces

Get Price Quote

conveyor furnace

Get Price Quote

Mesh Belt Conveyor Furnace

Get Price Quote

conveyor furnace

Get Price Quote

A multi-zone control environment is present in continuous high temperature furnace, often with a single pre-heating zone, followed by multiple heating zones and then cooling zones before exit.Due to the high temperatures involved most of these furnaces operate under controlled and protective atmospheres, with inert gases such as nitrogen and argon used for initial purging, and gas mixtures or gases like cracked ammonia or hydrogen or endogas used to create a suitable atmosphere as per process parameters.Specially designed corrugated muffles (metallic) are used to withstand thermal expansion for certain processes.

Continuous Conveyor Hardening

Get Price Quote

Process Capabilities Neutral Hardening & Tempering Carbonitriding Shallow Case Carburising Austempering Carbon Restoration & Hardening Consistency of quality is better obtained when components are continuously quenched, a few pieces at a time instead of in a batch at periodic intervals. Of the total tonnage of heat treated components the majority do not require fixturing and can tumble into a quench tank. The ideal plant for all such components in terms of quality, capital cost as well as operating cost is a continuous conveyorised heating and quenching system. Components spend less time at temperature and consume less energy compared to batch furnaces. Continuous quenching, a few components at a time, ensures a high degree of quality consistency in terms of hardness, case depth and physical properties. Such plants with conveyorised auxiliary equipment for loading, washing and tempering are normally fully automated. Equipment Features LOADING Soft handling, weigh feed, metered loading, vibratory conveyor, reciprocating feeder. WASH MACHINES High intensity jet spray, dunk & spray, steam wash, ultra sonic, vapour degreasing & in line centrifuge, drying, continuous dirt filtration, oil seperation/recovery, salt recovery. FURNACE Gas tight hardening furnace shell, microporous insulation, atmosphere circulation, alloy belt with raised edges & auto alignment, electric radiant tube heaters, multizone thyristorised temperature control, gas fired recuperative radiant tubes, waste heat recovery from spent atmosphere & by hot belt return, multi atmosphere capability, endogas generator, methanol dissociater, PSA, onsite nitrogen & ammonia cracker. QUENCHING Oil, hot oil or polymer, clog resistant cascade curtain, variable agitation, continuous dirt removal, air/water heat exchangers, air knife, electric heaters or gas tube burners, temperature, level & flow controls. TEMPERING High convection (high uniformity) tempering, rapid heat up feature, jet heating system, nitrogen atmosphere capability, steam tempering facility, post temper blackening tank. CONTROLS computer/touch screen HMI for user interface, SCADA programming based automatic plant and process control, production alarm & energy logging, several reporting formats. UNLOADING into bins, weigh & discharge, auto bagging with data acquisition. EXTRAS chiller tank (for 52100 steel parts, where required)

Conveyor Type Annealing Furnace

Get Price Quote

This machine is specially designed for Annealing Aluminium Tubes, Complete Fabricated and insulated. The Temperature of 450* C. with conveyor travel of 8mins prior to lacquer process. 10" or 18" conveyor can be design as per client requirement. The drive is through One H.P. motor and double reduction Gear Box.

conveyor furnace

Get Price Quote

Our conveyor furnaces are used for heat treating products where high volume production and low cost are favored. These furnaces are designed according to the customers’ process requirements and cycling time such as drying, preheating, curing etc. Uniform heating is achieved by mounting heating elements on support tubes, which facilitate high free radiation and excellent service life of the heater. The products are moved within the chamber on a mesh belt, supported by a belt drive made of rubber coated belt drums.

Electric Conveyor Furnace

800,000 Per Piece

CAST CONVEYOR BELT FURNACE

Get Price Quote

As we are aware that cast conveyor furnace requires continuous operations and in turns this requires high quality cast conveyor links which can last for several years with lowest possible maintenance and down time Since Cast Belts are expensive and cannot be replaced quickly quality is very important. We have tooling available for several types of cast conveyor links and moulds for most sizes of Deflector rolls and Drive rolls.

conveyor furnace

Get Price Quote

Working Temperature up to RT to 1000°C Material temperature up to RT to 400°C 100 kg to 5000 kghour capacity Tailor made size as per the customer requirement Kanthal heating element from Sweden 1°C accuracy at dwell temp Rapid heating rate(1 to 20°Cmin) programmable Imported indigenized Insulation Indigenous VBCC Make phase control thyrister controller Nippon PID programmable digital temperature indicator cum controller

Belt Conveyor Furnace

Get Price Quote

We manufacture fully automatic, semi automatic, manual mesh belt type continuous annealing furnace. We have also successfully exported similar equipment to usa

Mesh Belt Conveyor Furnace

Get Price Quote

The Mesh Belt Conveyor Furnace has been fabricated out of top notch quality raw materials that we have procured from our trusted vendors. They are furnished with brick refractory or molded ceramic fiber insulation, that is lighter, has less thermal mass, and lower thermal conductivity than conventional brick refractory. Application Bright hardening, low case depth carburising, bright quenching and carbonitriding Capacity (Nominal) 50 kg/hr. to 1000 kg/hr. Features Automated operation Automatic process control Consistency of results Controlled atmosphere operation Polymer quench (optional) Available in electrically operated and gas fired versions.

hydrogen atmosphere conveyor furnace

Get Price Quote

hydrogen atmosphere conveyor furnace, Furnace, Muffle Furnace

conveyor furnaces

Get Price Quote

conveyor furnaces, Air Heater, Cardamom Dryer, Refractory Mat

conveyor furnaces

Get Price Quote

conveyor furnaces, oil fired furnaces, Annealing Furnaces

Screw Conveyor Furnaces

Get Price Quote

Screw Conveyor Furnaces, Industrial Furnaces, aluminum melting furnaces

Screw Conveyor Furnaces

Get Price Quote

Screw Conveyor Furnaces, Industrial Furnaces, aluminum melting furnaces

Clay Heating Conveyor Furnace

Get Price Quote

We offer clay heating conveyor furnace. Working temperature up to rt to 1000°c material temperature up to rt to 400°c 100 kg to 5000 kghour capacity tailor made size as per the customer requirement kanthal heating element from sweden 1°c accuracy at dwell temp rapid heating rate(1 to 20°cmin) programmable imported indigenized insulation indigenous vbcc make phase control thyrister controller nippon pid programmable digital temperature indicator cum controller

Screw Conveyor Furnaces

Get Price Quote

Screw Conveyor Furnaces, Industrial Furnaces, aluminum melting furnaces