Frame Conveyor Idler

Get Price Quote

As we are acknowledged for providing high quality products to the clients, we make use of only superior grade raw materials as inputs. The selection of raw material is done by our experts. We provide customized packaging solutions, as we understand each customer is unique. The packaging we provide is strong, non-toxic, and capable of braving shipping and handling.

Self Aligning Frame

Get Price Quote

1 Pair (MOQ)

We are one of the prominent manufacturers and suppliers of quality Self Alignment Frame. They are made using premium raw- materials at our advanced infrastructure facility in cora with industrial quality standards. They are highly acdaim sturdiness and durability. Their resistance to corrosion makes them damage- resistant to a large extent. These pulleys are dimensionally accurate, owing to which, can be ea and maintained. They have a flawless surface finish and are light - weight as well. They enable easy portability. we offer them to our esteemed clients in customized specifications at economical prices. They are quality - tested before dispatch to ensure optimum end-user satisfaction.

Best Deals from Conveyor Idler

Conveyor Idler

2,000 - 2,500 Per Piece

5 Piece (MOQ)

Conveyor Idlers

Get Price Quote

Garland Idlers

1,000 - 2,800 Per Piece

200 Piece (MOQ)

Garland Idlers for Belt Conveyor The roll garland idler is a vital component in conveyor systems, designed to provide support and guidance for the conveyor belt. The garland idlers were originally developed to improve belt conveying of large conveying capacities and large lumps. APPLICATION Garland idlers are often used in applications where the conveyor belt requires extra support, such as in high-capacity conveyors, overland conveyors, or situations where the conveyor belt needs to navigate complex paths. They play a crucial role in maintaining belt alignment and minimizing friction, ensuring smooth and efficient material transportation in industries such as mining, construction, agriculture, and logistics Specifications of Garland Idlers Suspended Idler Set Type Belt Width Garland Idlers (Upper and Return, 2 Rollers) 500 - 2600 Garland Idlers (Upper and Impact, 3 Rollers) 500 - 2600 Garland Idlers (Upper and Impact, 5 Rollers) 800 - 2600 Roller Materials steel or stainless steel Standard DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

Belt Conveyor Idler

200 Per Meter

10 piece (MOQ)

Belt Conveyor Idler

Get Price Quote

We manufacture and supply technically advanced range of Belt Conveyor Idler, which is a vital component of Belt Conveyor. Our Belt Conveyor is made from superior raw materials due to which it renders consistent performance for longer period of time. Throughing idlers are generally used for conveying bulk materials and are available with side rollers inclined at 20"and 30". Idlers with 45"or other toughing angles can also be supplied in special cases. Types of Idlers Belt Rubber Cushion Idlers Return Belt Idlers Return Belt Rubber Tread Idlers Features Dimensional accuracy Robust construction High tensile strength Easy to install Reduce friction Save Power Durable Low maintenance High impact Anti-corrosive Endure operational temperature Cost effective Ideal For Airport Baggage Conveyor Port Trust Goods Belt Toughing Applications Crusher Conveyor Cement Plant Conveyor

Belt Conveyor Idlers

200 - 3,000 Per Piece

50 Piece(s) (MOQ)

Idler Supports the Conveyor Belt, Idlers are Roller that Spin Using Ball Bearings. They are Strategically Spaced Based On the Forces that Expected to Occur are Different Points in the Belt. the Spacing of Idlers Will Very Depending On the Forces Impacted On the Belt At a Given Place. Areas of Varying Spacing Include the Carrying Zones, Impact Zones and Spacing for Return Idlers. Furthermore Different Types of Idlers are Used Depending On the Required Belt Through Angles

Mild steel Conveyor Idlers

Get Price Quote

1 Piece (MOQ)

Mild Steel Conveyor Idler

Get Price Quote

Ms Conveyor Idler is a heat-resistant idler made of mild steel, suitable for industrial use. The idler comes in a standard size and is available in red and white color. The idler is designed to withstand high temperatures and is perfect for use in hot environments. The mild steel construction of the idler ensures durability and longevity. The Ms Conveyor Idler is an essential component of conveyor systems and is ideal for use in various industries.

Belt Conveyor Idlers

Get Price Quote

500 piece (MOQ)

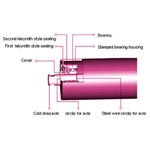

Features Roller Body: Shell is made of smooth surface ‘ERW’ steel tube as per IS : 9295 / IS 1239 Rollers End: Bearing Housing made of CRCA press steel sheet with calibrated bearing seat, which are welded with the periphery of the steel tube, for maximum strength. Spindle: M.S. bright bars / EN-8 / EN-9 & precision ground at bearing and seal seating areas. Bearing: Precision single-row deep groove ball bearings with C3 clearance are provided. Distance between bearings and point of support at the shaft is very short and thus ensure higher load carrying capacity and longer service life. Sealing: The double multi labyrinth seal ensures optimum protection against the entry of dust and dirt in to the bearings. The sealing arrangement consist of Inner Seal , Dust Cover & Rain Cap

Belt Conveyor Idler

Get Price Quote

PASHUPATI RUBTECH founded in 2005, leading manufacturer and exporter of conveyor rollers, Conveyor Idlers, conveyor belt, conveyor pulley and other related conveyor components in India. Our products and services has been widely adopted by worldwide mines, coal mine, power plant, steel plant, and so on.Features: Intricately manufactured Durability Easy to install Our Main Products: Conveyor Rollers: Carry Roller, impact roller, return roller, rubber disc roller. Conveyor Idlers: Troughing carrying idler, troughing impact idler, self-training idler, flat return idler, V-return idler, garland idler, 2 Roll assembly idler. Conveyor Pulley: Drive pulley, tail pulley, bend pulley, take-up bend pulley. Other Conveyor Components: Belt cleaner, impact bed and bar, other related conveyor components. Other Information Minimum Order Quantity: 1 Piece(s)

SS Conveyor Idler

550 Per Piece

conveyor return idler

Get Price Quote

We precisely design and manufacture our conveyor idler to give the maximum life under adverse operating conditions. Our exclusive range comprises of Troughing Idler, Rubber Disc Idlers, Troughing Training Idlers, Flat Belt Training Idlers and more. Possession of latest machines and manufacturing facility supports us to fabricate international standard conveyor idlers. We offer these conveyor idlers at competitive rates and insure their timely delivery. Idlers is one of the improtant part of Bulk material handling systems like Belt Conveyor and which is designed for Bulk material at any capacity and atmosphere

HDPE Conveyor Idlers

Get Price Quote

We are offering our entire range of products in excellent quality packaging to guarantee zero damage during transit. For this, we have hired only professional packing personnel to ensure the same. With substantial warehouse that is sprawling over large area, we have the capability to partner with management in performing the detail processes that require handling of the tasks such as sourcing, inspection, internal replenishment to picking positions, packing and shipping.

Conveyor Idlers

Get Price Quote

Our company is well-reputed as one of the eminent Idlers Manufacturers and Exporters from India. The array of the Conveyor Idlers offered by us includes carrying idler, the return idler, the impact idler, the centring idler, the spiral idler, the idler with rubber rings, etc. meeting the requirements of the applications. Moreover, the Industrial Conveyor Idlers possess minimum revolving resistance, long life, small maintaining work, high carrying capability and around 50000 hours of working life. Using the international standard design and manufacturing technology, our company improves the production and design of idlers to a higher level. The idler produced by our company enjoy min.revolving resistance, long life, small maintaining work and high carrying capability. The company adopts special fine welding steel pipe for idler, and does puncture processing in the tube. The roundness is controlled in special tolerance scope. The axle is according to standard tolerance and manufactured by fine cold drag steel. The bearing housing has been manufactured after stamping many times by the imported cold griped steel. The idler shell and bearing housing have been welded together by the automatic welding machinery hand. Then it forms a whole high strength structure. The bearing, which uses the world famous brand, is the big roving crack, deep groove ball and double sealing bearing. It makes the idler has the ideal static and dynamic balance that is better than the national standard. The company has done the special design and formed a particular our company seal way after integrating the overseas and domestic labyrinth seal style. It is filled with resisted high speed, high temperature and ultralow temperature antioxidant lithium. So it prevents the corrosion of the impurity, the water and the air effectively. The above technical conditions can guarantee the idler enjoy 50000 hours of working life. At present, the idler series products include the carrying idler, the return idler, the impact idler, the centring idler, the spiral idler, the idler with rubber rings, etc.

Belt Conveyor Idler

Get Price Quote

conveyer roller ideler

Get Price Quote

We offer our client an excellent quality range of Industrial Rollers, which are manufactured from high grade quality raw materials. These Industrial Rollers are widely known for its durability and quality ......

Conveyor Idler Set

1,500 Per Piece