Coordinate Measuring Machines

650,000 Per Piece

1 Piece (MOQ)

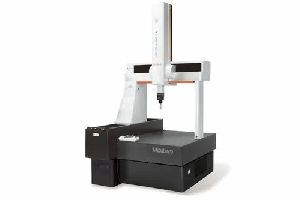

Coordinate Measuring Machine 1. Mechanical support.2. Softwares like Microsoft, Microprof, Microstat.3. Air dryer.4. Renishaw electronic probe kit comprising of:Electronic touch trigger probeStyli ps 8 r - 2.0 mm diaStyli ps 1 r - 3.0 mm diaStyli ps 9 r - 1.0 mm diaSc 2 5 way stylus centreSe 4 stylus extn. 10 . Mm5. Master reference sphere6. Clamping kitSc 2 5 way stylus centreSe 4 stylus extn. 10 . Mm7. Master reference sphere8. Clamping kitSize : X axis - 500mmY axis - 500mmTaag: Coordinate Measuring Machine Manufacture in Tamilnadu, Coordinate Measuring Machine Dealer in Chennai, Coordinate Measuring Machine Supplier in Tamilnadu Coordinate Measuring Machine Manufacture in Tamilnadu, Coordinate Measuring Machine Manufacture in Chennai, Coordinate Measuring Machine Manufacture in Kanchipuram, Coordinate Measuring Machine Manufacture in Tiruvallur, Coordinate Measuring Machine Manufacture in Cuddalore, Coordinate Measuring Machine Manufacture in Villupuram, Coordinate Measuring Machine Manufacture in Vellore, Coordinate Measuring Machine Manufacture in Tiruvannamalai, Coordinate Measuring Machine Manufacture in Salem, Coordinate Measuring Machine Manufacture in Namakkal, Coordinate Measuring Machine Manufacture in Dharmapuri, Coordinate Measuring Machine Manufacture in Erode, Coordinate Measuring Machine Manufacture in Coimbatore, Coordinate Measuring Machine Manufacture in The Nilgiris, Coordinate Measuring Machine Manufacture in Thanjavur, Coordinate Measuring Machine Manufacture in Nagapattinam, Coordinate Measuring Machine Manufacture in Tiruvarur, Coordinate Measuring Machine Manufacture in Tiruchirappalli, Coordinate Measuring Machine Manufacture in Karur, Coordinate Measuring Machine Manufacture in Perambalur, Coordinate Measuring Machine Manufacture in Pudukkottai, Coordinate Measuring Machine Manufacture in Madurai, Coordinate Measuring Machine Manufacture in Theni, Coordinate Measuring Machine Manufacture in Dindigul, Coordinate Measuring Machine Manufacture in Ramanathapuram, Coordinate Measuring Machine Manufacture in Virudhunagar, Coordinate Measuring Machine Manufacture in Sivagangai, Coordinate Measuring Machine Manufacture in Tirunelveli, Coordinate Measuring Machine Manufacture in Thoothukkudi, Coordinate Measuring Machine Manufacture in Kanniyakumari, Coordinate Measuring Machine Manufacture in Krishnagiri, Coordinate Measuring Machine Manufacture in Ariyalur, Coordinate Measuring Machine Manufacture in Tiruppur

Coordinate Measuring Machine

Get Price Quote

Best Deals from Coordinate Measuring Machine

Coordinate Measuring Machine

Get Price Quote

We are offering coordinate measuring machine. the gmt coordinate measuring machine (cmm)(grano 6-7-5) is the culmination of decades of experience in metrology and machine tools. Gmt cmm's are the ideal measurement systems for small-to-medium sized free-form and prismatic components. a wide variety of state-of-the-art accessories are provided with gmt bridge-type coordinate measuring machines to suit all dimensional inspection tasks and needs. All gmt cmm's are designed and manufactured with proven technology and air bearings for frictionless travel. gmt constantly researches new materials such as composites to incorporate in its machines to achieve the required dynamic performance.

Precision Horizontal Arm Machine

Get Price Quote

Coordinate Measuring Machine

Get Price Quote

Coordinate Measuring Machine

Get Price Quote

Xtreme Shop Floor CNC CMM for precision measurements in even the most extreme manufacturing environments – coordinate measuring machine accuracy wherever you need it. To know more about the product visit/p>

assy cross member

Get Price Quote

Being a client centric organization, Jagjit Enterprises Private limited is submerged in presenting premium quality assy cross members for our buyers. We are also extensively fascinated in manufacturing and supplying a quality assured cross member assembly and end cross member. Our assy cross members are widely used in reputed automobile industries. These cross members are extremely robust and durable in nature. We are backed with a dedicated team of professionals to manufacture and deliver quality products as per the industry standards. Our assy cross members are also launched in the international market to approach international clients. You can get these assy cross members online with us at an economical rate.

Coordinate Measuring Machine cnc

2,200,000 Per Pack

1 Pack(s) (MOQ)

Tespa Coordinate Measuring Machine (EXATO)

1,900,000 - 7,000,000 Per piece

1 piece (MOQ)

Coordinate Measuring Machine

Get Price Quote

The Coordinate Measuring Machine, as the name suggests, is used to precisely calculate the coordinates of a particular area for advanced calculation. This machine is of immense importance in determining and predicting the specifications of a particular area. We supply these machines to all our national clients, especially colleges and research institutes. Our machines last longer than most others and produce most accurate results that are displayed in a user friendly manner.

Optical Coordinate Measuring Machines

Get Price Quote

Zeiss Contura Bridge Type CMM Machine

Get Price Quote

Make payment securely with a payment option you are comfortable with. We accept payment through offline as well as online modes. We make sure proper documentation is done. Keeping the quality standards high, we make certain that prior to production, the inputs (raw material) are examined by the professionals to make the final product free from defects. Sensor variations : ZEISS CONTURA comes with a fixed passive sensor, the flexible RDS articulating probe holder or with an active scanning probe. All sensor variations enable scanning. ZEISS navigator technology comes standard with the active version – for smooth measurements without a stop & go. Robust and precise : Depending on the configuration, ceramic or CARAT guideways are used on ZEISS CONTURA for high rigidity, low thermal expansion and minimal moving weights. Air bearings in all three axes ensure consistent stability even at high travel speeds and acceleration. The floating glass ceramic scales on ZEISS CONTURA are practically expansionfree and therefore do not require any additional temperature sensors or mathematical compensation. They are suitable for the shop floor and are protected against contamination and other influences. Computer-Aided Accuracy (CAA) : The bridge is subjected to dynamic forces that can affect accuracy, particularly while scanning. ZEISS CONTURA calculates the compensation for such inertia effects. This ensures that the required precision remains intact even at high measuring speeds. Convenient control : The system is controlled via a userfriendly control panel and does not need a computer. The progressive joystick enables easier and more precise control of all axis movements. The speed can be regulated in CNC mode. Options HTG (High Temperature Gradient) for a larger temperature range (18-26°C) with the same measuring uncertainty. Features temperature sensors for the workpiece and measuring machine. Available for x= 700/1,000 mm Integrated sensor rack for maximum reproducibility without recalibration QuickChange fast sensor change-out for active probes ZEISS AirSaver for up to 60% less consumption of compressed air Sensor variations Direkt : The direkt sensor model is ideal for the measurement of small parts with perpendicular geometries without inclined features. Equipped with the ZEISS VAST XXT scanning sensor, ZEISS CONTURA direkt provides a particularly affordable means of entering the world of scanning technology from ZEISS for production and progress inspection of single processing stages. The alternative XDT single-point sensorcan be retrofitted on VAST XXT from ZEISS as needed. ZEISS CONTURA direkt is available up to a size of 10/16/6. RDS : Combined with the VAST XXT sensor from ZEISS, the flexible, RDS articulating probe holder enables the scanning of features in all angular positions. With a total of 20,736 positions at 2.5° increments, RDS can reach virtually any spatial angle. This is particularly advantageous for the measurement of complex parts, for which specific stylus configurations have to be created. Calibration times are kept to a minimum thanks to optimal calibration routines. RDS also enables the use of optical sensors from ZEISS on ZEISS CONTURA. Aktiv : ZEISS CONTURA aktiv comes standard with navigator technology for fast scanning in one smooth run. It can be operated with the VAST XTR gold or VAST XT gold active scanning probes from ZEISS – and is particularly wellsuited for the measurement of deep and offset features with high throughput rates. Both sensors use the same receptacle. Existing measuring programs can be used following conversion. The QuickChange fast stylus change-out system is also an option. Available Software CALYPSO GEAR PRO Available Sensors LineScan RDS VAST XT gold VAST XTR gold VAST XXT ViScan

Coordinate Measuring Machine

Get Price Quote

The Galaxy H Coordinate Measuring Machine (CMM) is a manual-controlled horizontal arm measuring and layout machine built to perform common shop measurements and marking-out applications. This cost-effective solution is available in single, double or in multi-arm configurations. The Galaxy H is compatible with different models of probing heads from Renishaw. Its repeatable indexing for up to 168 different positions eliminates the need to re-qualify the stylus tip position after orientation.

Coordinate Measuring Machines

Get Price Quote

We are offering a range of coordinate measuring machine (cmm), which is a device used to measure the physical geometrical attributes of an object. The range can be controlled manually by an operator or can be computer controlled as well. Measurements are taken with the help of a probe that is attached to the third moving axis of the range. The probe can be optical, mechanical, white light, laser or others.

Coordinate Measuring Machine

Get Price Quote

01 Piece (MOQ)

Coordinate Measuring Machines

Get Price Quote

We are offering coordinate measuring machines. The range can be controlled manually by an operator or can be computer controlled as well. Measurements are taken with the help of a probe that is attached to the third moving axis of the range. The probe can be optical, mechanical, white light, laser or others. We are leading manufacturer and supplier and looking queries from south india.

3d coordinate measuring machine

Get Price Quote

We offer coordinate measuring machine. jash offers co-ordinate measuring machines to suit wide variety of measurement applications meeting international quality norms.

3d coordinate measuring machines

Get Price Quote

Salient Features Moving Bridge Type SIGMA Series Adopted with a state-of-the-art designing technology being of high accuracy & convenience. A special design concept in consideration of human engineering, emotion engineering & improving the accuracy by making the machine reliable and secure. A maximized measuring efficiency by extended the measuring range and improved accuracy. Volumetric error compensation by error mapping software. Optional Modules: Scanning / Digitizing for Reverse Engineering SurfaceInspection Profile Analysis Surface Inspection 3D Bent Tube Inspection & Analysis CAD / CAM Connectivity Gear Inspection Car Body Line Inspection Standard features: Useful for measurement of prismatic objects or complex shapes Reduced measuring time of economized energy Strong structure assures a excellent durability High level accuracy of measuring work Optional Accessories: Clamp Kit Air Dryer (Air / Oil Filter)

Portable Coordinate Measuring Machine

Get Price Quote

Coordinate Measuring Machines

120,000 Per Unit

Coordinate Measuring Machines

2,500,000 Per Piece

Coordinate Measuring Machine

150,000 Per Piece

1 Piece (MOQ)

Portable Coordinate Measuring Machine

2,500,000 Per Piece

1 Piece (MOQ)

3d coordinate measuring machines

Get Price Quote

We offer 3d Coordinate Measuring Machines. Entry level machine with power packed features for 3D measurement of small parts. Designed for ease of operation and safety ensuring optimum performance. Features: Elevated Bridge All granite construction for measuring axis manual operation Increased protection for measuring guides. Choice for various probing system. Machine ready for Plug & Play Package includes PC, Air Dryer and clamping Kit.

Portable Coordinate Measuring Machine

Get Price Quote

Coordinate Measuring Machine

Get Price Quote

Coordinate Measuring Machine

650,000 Per Piece

1 Piece (MOQ)

Coordinate Measuring Machine

Get Price Quote

Optical system provides bright and clear images. Air bearings on the X and Y axis for extended productivity. High quality German made edentulous lead screw are used on the machine. Long-life LED ring provides a cold light source that will not produce thermal deformation. Panasonic three-axis servo motor drive. Solid granite base and column for increased stability.

Portable Coordinate Measuring Machine

2,500,000 Per Units

Manual Coordinate Measuring Machine

Get Price Quote

We are offering coordinate measuring machine. the best cmm value anywhere in the world designed for your shop. checkmaster reliability the compact checkmaster is a bench top cmm ideal for lab or production floor. Hardened stainless steel ways and steel scales on steel structures offer uniform linear expansion minimizing thermal errors. The low cost means you can put competent inspection capability in multiple locations throughout your plant. intrinsic accuracy manual cmms we test every cmm before it leaves the factory for repeatability and accuracy, that meets or exceeds the industry standards as defined in ansi b89.4.1a-1998. Our testing includes a repeatability test that exceed a minimum of 150 cycles, often recording a total range of 2.0 µm (0.00008") or better! these stringent targets are maintained without the need for expensive software compensation maps. Our goal is to build the cmm mechanically correct that will deliver the results you expect, year-after-year. every checkmaster is designed and packaged for fast and secure installation by the customer. All key components are protected during shipping by specially designed brackets, that when removed, ensures the cmm is ready for your first inspection. the ideal scanning system not every reverse engineering job requires expensive motorized cmms. The checkmaster using the geomet junior software provides tools such as geotracer which allows you to capture large data data point clouds using low cost hard probes. Ideal for outline tracing! geomet junior the software is preinstalled in the supplied windows xp computer system. One usb connection from the cmm interface is all that is required to complete the system. A user guide is provided with easy-to-follow tutorials including sample inspection programs. Geomet maintains a web site dedicated to geomet. Through this site, you will have the latest access to software upgrades and a full online manual that can be accessed directly through your cmm and geomet. would you like more information? please use our information request form. standard configuration •granite worktable •38"-16 clamping inserts (m10 optional) •locks on all three axes •usb procounter ii interface •zero-play fine adjustment on all axes •custom key labels •electronic touch probe interface •calibration sphere •geomet junior software •windows xp •pentium computer system •geomet junior user guide •geowidget training part •1-year cmm warranty •online access to software upgrades cmm specifications measuring range model number x y z 112-102 300mm (12") 300mm (12") 250mm (10") 216-142 400mm (16") 500mm (20") 350mm (14") overall size model number x y z 112-102 635mm (25") 685mm (27") 965mm (38") 216-142 735mm (29") 915mm (36") 1150mm (45") model number scale resolution repeatability volumetric accuracy 112-102 .5 µm (0.000020") 4 µm (0.00014") 8.6 µm (0.00034") 216-142 .5 µm (0.000020") 4 µm (0.00014") 9.6 µm (0.00038") linear accuracy : 0.00016" + 0.000005" per inch mpep : 4.5 µm mpee : 4.5 µm + l200, (l = measured length in mm) performance per ansi b89.4.1a-1998 : standard is based on dynamic measurements with electronic probe and 200mm or 300mm ball bar. mechanical accuracy is intrinsic without volumetrically compensating through software. tests are conducted at standard 68°f (20°c) and 50% humidity. weight : 112-102 : 69kg (153 lbs) 216-142 : 113 kg (250 lbs)