copper boron metal alloy

3,200 Per Kilogram

1 Kilogram (MOQ)

Copper Boron 2% is metal alloy available in the form =of shots and wire. Widely used in Soldering / earing Assembly / Deoxigenation / Grain refining

Copper Alloys

Get Price Quote

Phoolchand Bhagatsingh is a company that supplies, imports, and exports various metals and metal alloys, including tin metal ingots.Phoolchand Bhagatsingh is a reputable supplier of various metals and metal alloys, including tin metal ingots, and that they have implemented a quality management system that is in line with international standards. Copper alloys are materials that are composed of copper as the primary metallic component, with one or more additional elements added to provide desired properties. These additional elements may include tin, zinc, nickel, aluminum, lead, phosphorus, and silicon, among others. Copper alloys are valued for their high electrical and thermal conductivity, as well as their good corrosion resistance, ductility, and machinability. They are used in a wide range of applications, including electrical wiring, plumbing, industrial machinery, and decorative objects. Some common copper alloys include: Brass: an alloy of copper and zinc, commonly used in plumbing fixtures, musical instruments, and decorative objects. Bronze: an alloy of copper, tin, and sometimes other elements, commonly used in statues, bells, and decorative objects. Cupronickel: an alloy of copper and nickel, commonly used in marine applications due to its resistance to corrosion and biofouling. Phosphor bronze: an alloy of copper, tin, and phosphorus, commonly used in springs, bearings, and electrical contacts. Aluminum bronze: an alloy of copper, aluminum, and sometimes other elements, commonly used in marine hardware, springs, and electrical contacts. Overall, copper alloys are important materials in a variety of industries due to their unique combination of properties, including high conductivity, corrosion resistance, and machinability.

Best Deals from Copper Alloys

copper arsenic alloy

810 Per Kilogram

100 Kilogram (MOQ)

The Copper Arsenic master alloy is used in both ferrous as well as non-ferrous industries. The arsenic is added in low concentrations to improve the corrosion resistance of aluminum bronze, while small additions to brasses inhibit dezincification under certain corrosive conditions.

Copper Manganese Alloys

785 - 810 Per Kilogram

300.00 Kilogram (MOQ)

C36300 Copper Lead Zinc Alloy

600 - 650 Per Kilogram

500 Kilogram (MOQ)

Copper Alloy

500 - 800 Per PER KG

White Copper Parad Alloy

Get Price Quote

100 Kilogram (MOQ)

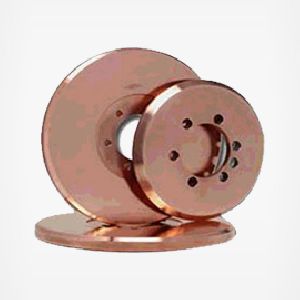

Beryllium Copper Alloys

3,500 - 12,000 Per Kilogram

Beryllium copper alloy is a high strength alloy with non-sparking and non-magnetic qualities. The alloy supports outstanding metalworking, forming and machining and is suitable for the shafts of seam welding machines, for electrode holders, inserts for dies and load bearing components.Standards : Indian Standard: IS 8365 International Standards : ASTM B196 C-17200, DIN 17672 WN2.1247, ISO CuBe2, BS EN CW101C

Beryllium Copper Alloys

Get Price Quote

C18000 Copper Chromium Nickel Silicon, C15000 Zirconium Copper

Copper Pro Copper Alloy Microstructure Analysis Software

Get Price Quote

Beryllium Copper Alloy

Get Price Quote

Hitesh steel offer our clients a wide spectrum of beryllium copper alloy which is mainly demanded in varied industries for its different applications. These products are procured from most trustworthy vendors of the market. They ensure that these products are manufactured using high grade raw material and advanced technology. Our products are available in varied specifications as per the details given by our clients. Features: * longer service life * precision engineering * resistant to corrosion. Products: ss buttweld fittings

Chromium Zirchonium Copper Alloys

Get Price Quote

gilding metal

Get Price Quote

It is further alloyed with different metals to obtain desired characteristics. We are very complimented among our supporters for offering this range. Attributable to the finest crude materials utilized as a part of its making, its strength, durability, protection from consumption and dimensional exactness, make the item exceedingly estimable. Our Brass Plates are generally utilized as a part of various mechanical segment and we acclaimed prominent position in this industry.

Copper Nickel

Get Price Quote

copper nickel is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. Copper nickel is highly resistant to corrosion in seawater, because its electrode potential is adjusted to be neutral with regard to seawater. Because of this, copper nickel is used for piping, heat exchangers and condensers in seawater systems as well as marine hardware, and sometimes for the propellers, crankshafts and hulls of premium tugboats, fishing boats and other working boats. A more familiar common use of copper nickel is in silver-colored modern circulation coins. A typical mix is 75% copper, 25% nickel, and a trace amount of manganese. In the past, true silver coins were debased with cupronickel. Despite high copper content, cupronickel is silver in color. It is used in thermocouples, and resistors whose resistance is stable across changes in temperature contain the 55% copper-45% nickel alloy constantan. Monel metal is a nickel-copper alloy, containing minimum 63% nickel. uses single-core thermocouple cables use a single conductor pair of thermocouple conductors such as iron-constantan, copper constantan or nickel-chromiumnickel-aluminum. These have the heating element of constantan or nickel-chromium alloy within a sheath of copper, copper-nickel or stainless steel. Beginning around the turn of the 20th century, bullet jackets were commonly made from this material. It was soon replaced with gilding metal to reduce metal fouling in the bore. Currently, cupronickel remains the basic material for silver-plated cutlery. It is commonly used for mechanical and electrical equipment, medical equipment, zippers, jewelry items, and as material for strings for string instruments. For high-quality cylinder lock and locking systems, the cylinder core is made from wear-resistant copper nickel.

Tin Copper Alloy

Get Price Quote

Copper Alloy broad array of Copper Alloy

Get Price Quote

C36300 Copper-Lead-Zinc Alloy

600 - 650 Per Kilogram

250 Kilogram (MOQ)

Copper Alloy

Get Price Quote

Commercial Aluminium Alloys

Get Price Quote

1 Ton (MOQ)

Beryllium Copper Alloy

2,500 Per 4500 Kilogram

1 Kilogram (MOQ)

Beryllium Copper Alloy

Get Price Quote

100kg Kilogram (MOQ)

We are offering rising metals and alloys is a brand name for ferrous and non ferrous metals. We have pleasure to introduce ourselves as a one of the leading stockiest, supplier and exporter of stainless steel , alloy steel , copper , brass , aluminium , phosphor bronze , gun metal , nickel and other ferrous and non ferrous metals in the shape of pipes , tubes , rods , wires , hex , square bars, sheet , plates , coils , strips and entire range of pipe fittings such as bw sw screwed forge and compression type of ferrule such as elbows , tees reducers , stub ends , flanges etc. We have a track record for the supply of stainless steel items for almost 2 decades now.

Tellurium Copper Alloys

Get Price Quote

copper base alloys

900 Per Kilogram

50 Kg (MOQ)

Copper Alloy

Get Price Quote

Owing to our expertise in this domain, we are offering our clients a broad assortment of Copper Alloy

Tin Copper Alloy

2,400 - 2,900 Per Kilogram

10 Kilogram (MOQ)

Brazing Consumables

Get Price Quote

filler rods and wires copper alloys (tig/mig) silver alloys (tig/mig) flux coated brazing copper alloys silver alloys .

Copper Alloys

Get Price Quote

Copper Brazing Alloys

Get Price Quote

Copper Brazing Alloys are known for their various unique features. We manufacture these Copper Brazing Alloys as per the prescribed standards of quality of markets. We have gained prestige on the base of the quality and popularity of these Copper Brazing Alloys. The accurate composition, melting range, of copper phosphorus brazing alloy is the trusted factor of the keep growing demand of these Copper Brazing Alloys. Brazing alloy is particularly adaptable when close fit cannot be held. This filler metal may be used where narrow joint clearance cannot be held. It has the ability to fill wide joint clearances at the lower end of its brazing range. At the high end of the brazing range, it is more fluid. Based on the quality of these Copper Brazing Alloys, we have positioned on the top in the market. Acknowledged For :-Accurate compositionMelting rangeAdaptable when close fit cannot be heldUsed where narrow joint clearance cannot be heldAbility to fill wide joint clearances at the lower end of its brazing rangeHigh end of the brazing range, it is more fluid SpecificationsCopper and Copper Alloy Filler Rods"TECH-BRAZE" Grade of Brazing AlloyNominal Composition %Melting RangeAgCuZnNiSiSnoCSB - 1009-6039.7-0.3-890-900NB - 1010-5039.7100.3--SB - 100116038-0.50.5900 - 940NB - 10071533870.50.5900 - 940

Copper Alloys

Get Price Quote

Copper and its alloys including sheet, plate, machining bar and hollow bar, flat bar, hexagon bar and tube. In addition to a comprehensive range of standard sizes

copper master alloys

Get Price Quote

A master alloy is a base metal such as aluminium, copper or nickel combined with a relatively high percentage of one or two other elements. An example is AlTi10 – a binary alloy consisting of 10% titanium in aluminium. A master alloy is a semi-finished product. It is manufactured for use as a raw material by the metals industry. Master alloys are produced in various shapes.A wide variety of high-quality master alloys are used as alloying elements to improve selective mechanical properties of our customer’s final alloy products. The unique combination of physical and mechanical properties of many of our master alloys provide a dynamic range of metallurgical alternatives to meet specific performance requirements.