Corrosion Test Chamber

20,000 - 50,000 Per Piece

Salt Spray Corrosion Test Chamber

Get Price Quote

Best Deals from Corrosion Test Chamber

Salt Spray Corrosion Test Chamber

Get Price Quote

Touch Tone Salt Spray Fog Tester is used to test the corrosive resistance of products whose the surface was treated with paint, electroplating, inorganic and organic film, anode handling, anti-rust oil.

corrosion test chambers

500,000 Per Piece

corrosion test chambers for testing corrosion in multy cycles , PLC And HMI . fully automatic machine.

Cyclic Corrosion Test Chambers (CCT)

Get Price Quote

Mett-Bio Metallurgical Testing & Services an ISO 17025:2005 accredited by NABLis fostering its industry-leading reputation for being the dominant firm in Metallurgical and Corrosion Testing as per NACE/ASTM /ISO Standards. Mett-Bio Is pleased to offer Cyclic Corrosion Testing (CCT)services as per ASTM G 85. · Cyclic Corrosion Test (CCT)

Corrosion Test Chamber

Get Price Quote

Corrosion Test MASTER i9Junior (Touch Panel, Digital)

100 - 200 Per

1 Piece (MOQ)

Corrosion tester is the most reliable equipment for checking the corrosion resistance of surface coatings when exposed to a salt laden environment. This time-tested product has been specifically designed to assess the rust-proof ability of components to withstand corrosion due to atmospheric conditions. It provides complete flexibility in simulation of real life weathering conditions. The device is used in industrial testing laboratories for various research and analysis purposes. The instrument is capable of creating very high temperatures for testing and studying the effect on different painted and plated metal substrates. Paramount Corrosion Test Master Junior i9™ is a Next Generation Equipment with a Touch Panel control to perform accurate testing. T he test temperature in the chamber is user adjustable from ambient to 40 °C and is controlled by a PLC controlled Touch Panel HMI Unit. The touch screen is a powerful tool that eases the analysis of corrosion resistance for a wide variety of sample types. A special zero corrosion RTD sensor is incorporated in the Equipment for Accurate & Reliable results.

Copper Strip Corrosion Standard

Get Price Quote

As per IS;1448,IP:154 & ASTM-D-130-88 to find out the presence of corrosive sulphur in petroleum.The apparatus consists of a dual purpose (500 & 1000C) Water bath to accommodate 6 bombs or18 test tubes of specified dimensions. The bath with 6 holes and individual cover with suitable hook for hanging bombs and to keep the bath holes closed. Inner chamber of S.S.with motorised stirrer. with Digital Temperature control-cum indication of set temp.

corrosion test chambers

Get Price Quote

Due to their modular structure, our tests Corrosion Test Systems offer manifold test options up to full automation. Operation using the graphic screen is conceivably easy. Our different possible solutions are satisfactory for all customer-specific requirements.Serial production instruments, Customer-specific chambers, High temperature resistant and heavy weight resistant constructions, Development of customer-specific test processes.

Cyclic Corrosion Test Chambers

Get Price Quote

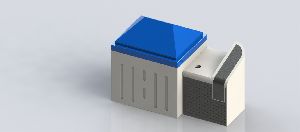

Ascott make Cyclic Corrosion Test Chambers are one of the most sophisticated and versatile Cyclic Corrosion Test Chambers available in the World market. Ascott has been at the fore front of Test Chamber design for many years and their latest product range embodies customer led innovation, blending performance with technical excellence. The creation of control and corrosive climates has never been more demanding. The development of new materials and surface coatings, plus increasing user expectation gives rise to ever more rigorous testing. These Chambers are supplied with various internal volume size ranging from 450 litres to 2000 litres which can be selected depending upon the sample specimen size and the weight. These Chambers has pneumatically operated canopy which automatically opens and closes and has many safety features like automatic purging of the salt fog before opening the canopy (hood). They also have a very low loading threshold for ease of loading unloading of heavy samples. There are many special features that are incorporated as standard part of the system which makes it the most versatile and the chosen one for all the reputed customers Worldwide. These Cyclic Corrosion Chambers are set with new standards in corrosion testing and conform to all international testing standards, including ASTM, DIN, ISO, IEC, JASO and VDA, as well as automotive test standards for Ford, Honda, GM, VW, Toyota, Renault, Volvo and many more.

Corrosion Test Chamber

Get Price Quote

We are offering Corrosion Test Chamber. ENVIRONMENT TEST CONDITIONS: Environment temperature range: 15 ~ 60 Relative humidity: Less than 85%R.H. Atmosphere: 86 ~ 106 Kpa Without strong vibration around Without strong electromagnetic field around the influence, no high concentration of dust and corrosive materials Avoid direct sunlight or other heat source direct radiation Without strong airflow around, when the surrounding air should be forced to flow, flow should not blows directly to the body Machine should be placed flat, maintain the level, because the upper water seal to prevent salt fog spillover Around the machine there shall be a certain distance, convenient maintenance operation MACHINE INTERNAL: Spray tower (or baffle type): Invisible glass shower nozzle in nozzle interior, spray by tower tube guidance, then through conical disperser (or baffle) evenly dispersed spray to the laboratory internal. Spray regulator: Adjust spray amount, adjustable high spray on the conical disperser (or baffle) spray quantity increase, the lower the spray to decrease, brine preheater tank, located in spray bottom department, the tank brine is the brine added box injection preheating tank, the water level of preheating tank by floating ball control, automatic control level, the groove bottom have for washing port, port by silica gel plug control. Collector: Nozzle have eruptive fall fog quantity to free-fall way down to 80 cm of the funnel cup inside, again by duct flow to measuring cup inside. Shelf: The shelves of window of model steel is made, pool weight can't more than 2 kg, if place dispersedly samples, affordable 10 kg weight within the supporter and lined with two rows round hole, round hole is for placing buy object bar, vertical plane is divided into 15 degrees and 30 degrees. Heating water tanker: This tank adherent to the laboratory bottom, used to hold water humidifying keep laboratory temperature smooth, have added wet and heat preservation function. MACHINE EXTERNAL: Measuring pail: It collects the spray quantity, the highest scale is 50ml. Insulated tank: Use water principle, avoid salt fog were leaked. Saturated air barrel: Placed in control bottom part, USES the SUS304 stainless steel plate is made, its function lies in the air after the barrel warming humidification, allowing air to saturated humidity to the nozzle spray. Test cover: Roof type bevel 100 degrees perspective cover, and used to cover in the laboratory, combined as one body. Pressure regulating valve: Manual regulation inlet pressure and spray pressure inlet pressure control in 0.4 MPa, the spray pressure control in 0.07 ~ 0.17 MPa. Pressure meter: This table pointer shows pressure is air after saturated air barrel heating, communicate spray or reach pressure. Exhaust pipe: 1/2 diameter pipeline, combining drain to drain, make its wastewater which ruled out. Water inlet: Supplementary laboratory and saturation bucket of water to normal usage.

cyclic corrosion test chamber

Get Price Quote

Salt Spray Corrosion Test Chamber

Get Price Quote

Whether you are new to corrosion atmosphere testing or have been conducting testing for years, we present Salt spray chambers or Salt Fog Chambers that are not only easy to use and maintain but also provide the accuracy and flexibility necessary to meet today's demanding corrosion test procedures including Salt Spray Test, Condensation Water Test and Cyclic Corrosion Test. These machines create three types of manually adjusted environment; salt spray, high humidity and air drying at any given temperature within the chamber. Any combination of these environments can be programmed, in any order, to form a corrosion cycle. Such a corrosion cycle can be automatically repeated a predetermined number of times

Corrosion Test Chamber

Get Price Quote

TLPPL 137 TECHNICO SALT SPRAY CORROSION TEST CHAMBER

Get Price Quote

Technico salt spray test chamber entire is constructed by thick polypropylene or acrylic sheet body. The top lid door will be made of transparent Acrylic. The solution reservoir is separated externally in a cylindrical vessel and fixed to the side of the main chamber. The solution is sprayed inside the chamber by means of compressed air (Air compressor not in our scope) and its level is controlled by float valve. The main chamber is provided with transparent acrylic cover lid mounted on fabricated acrylic hinges. The top lid closes the entire chamber without fog leakage. The saturation tower and the control panel are attached with the sidewall of the main chamber. The control panel is made of FRP material. Solution and water drain out tap are also provided. Suitable specimen holders and job holding devices are furnished inside the chamber. Technical Specification: Chamber temp. : 35 C Control accuracy : 3 C Saturation tower temp. : 40 C to 45 C. Controller type : PT- 100( RTD type) Temperature controller: Size : 48 x 48 mm Type : Digital Humidity Indicator: Size : 48 x 48 mm Type : Digital Digital Timer: Make : Selectron Size : 72 mm x 72 mm Hours : 999.9 hrs Pressure gauge: Range : 0 – 4.2 kg/cm2 Range : 1 kg/cm2 (saturation tower). Solution tank : 5 % of the sodium chloride (100 lit) is prepared and poured in the chamber reservoir. It is passed to the spray tower through the mechanical float through which is maintaining the water level in the tower. POWER SUPPLY: The chambers plug pin should be connected to the power supply & the timer to be set according to the testing hours. PRESSURE REGULTOR WITH GAUGE: The compressed air enters to the solenoid valve. It is controlled by the help of pressure regulator (15 lbs.) in pressure gauge. When the testing specimen or components are loaded to the chamber. The drain out valve is kept open because the condensed for water should not touch the specimens STANDARD SIZE: 600 x 600 x 600H or 600 x 900 x 900H.

Corrosion Test Chamber

Get Price Quote

The Sulphur Dioxide Test Chambers from Weiber are Corrosion Test Chambers used for testing the corrosion resistance of metallic surfaces and outer protective layer of coatings. They are used to create a highly corrosive environment rich in corrosive gases and natural humid conditions to induce accelerated corrosion in protective coatings of machines and equipments, electrical items, electronic parts and components, mechanical constructions, automobile and aircraft parts and components etc. Since the corrosive action of Sulphur dioxide also depends on specific temperature and humidity conditions and the presence of other contaminants, the Weiber Sulphur Dioxide Test Chambers are designed to create optimal conditions of temperature and humidity and also make provisions for introducing impurities and contaminants. These equipments operate across a wide temperature range, creating variations in the working temperature to mimic a natural weathering environment. The SO2 Test Chambers from Weiber are designed in accordance with international standards and can be completely customized according to specific requirements. They use advanced and sophisticated technology to ensure safe and reliable operation and are easy to use and maintain. These equipments are available in visually appealing aesthetic designs and find widespread usage in industrial manufacturing units and research organizations. They are designed for diverse and versatile applications and often function as fog test chambers and automobile accelerated corrosion test chambers.

Corrosion Test Chamber

Get Price Quote

Corrosion Test Chambers also called as Salt spray Chamber, The SF series of corrosion test chambers are designed to meet the requirements of all major international test standards. For more details download SF brochure.

Corrosion Test Chamber

Get Price Quote

Whether you are new to corrosion atmosphere testing or have been conducting testing for years, we present Salt spray chambers or Salt Fog Chambers that are not only easy to use and maintain but also provide the accuracy and flexibility necessary to meet today's demanding corrosion test procedures including Salt Spray Test, Condensation Water Test and Cyclic Corrosion Test. These machines create three types of manually adjusted environment; salt spray, high humidity and air drying at any given temperature within the chamber. Any combination of these environments can be programmed, in any order, to form a corrosion cycle. Such a corrosion cycle can be automatically repeated a predetermined number of times. Our models meet the requirements of basic, continuous salt spray tests conducted at a single temperature only, such as ASTM B117 and similar international test standards, and may be used with pH neutral salt solutions (NSS) or those acidified by the addition of Acetic Acid (ASS), Seawater Acidified Test (SWAAT) or Cupric Acid (CASS). Models above 480 Liters of capacity are ideal for Cyclic Corrosion Cabinet (Cyclic Corrosion Chamber). In Laboratories corrosion tests are used extensively for selection of materials and their surface protection. Our Corrosion box chambers are what you need to predict corrosion resistance of materials such as paints and coatings and are designed and developed to meet the widest possible range of industry standards: • Salt fog testing as specified in DIN 50021 • Condensed water test as specified in DIN 50017 and EN ISO 6988 • Standard climates as specified by DIN 50015

Corrosion Test Chamber

Get Price Quote

Corrosion Test Cabinet as box containers enable optimum usage of space, Manifold testing options from salt spray tests to fully automated replacement tests, Easy to operate using the graphic menu navigatio, Customer-specific applications for many special applications, Simple operation using a touch panel

Corrosion Test Chamber

Get Price Quote

The Presto salt spray chamber is the most reliable equipment for checking the corrosion resistance of surface coatings when exposed to a salt laden environment. This time-tested product has been specifically designed to assess the rust-proof...