Purafil OnGuard 4000 Corrosion Monitor

295,000 - 300,000 Per piece

1 piece (MOQ)

Purafil OnGuard 4000 Corrosion Monitor

275,000 - 325,000 Per piece

1 Piece (MOQ)

ONGUARD 4000The Purafil OnGuard 4000 (OG4) Atmospheric Corrosion Monitorindicates the level of corrosion before severe damage occurs, preventing costly downtime and maintenance repairs. Reactivity monitoring is an accu- rate and reliable method of evaluating the quality of air, characterizing the room environment, and evaluating the effectiveness of chemical filters. The OG4’s copper and silver sensors measure the rate of corrosion in real-time. An internal data logger stores the results to be accessed through the internet or directly transmit to a process con-trol system. Ideal for control rooms, server rooms, motor control centers, rack rooms, or other areas where corrosion is a concern, the OG4 prompts preventive action beforeserious problems develop. Benefits•Indicates the level of corrosion before severedamage occurs• Prevents costly repairs and production downtime•Tracks peaks and trends to determine the level ofcorrosion• Easy access to data and graphs• Readings correspond to ISA Standard 71.04-2013•Low maintenance: Sensors need replacement at 4000Angstroms of cumulative corrosion growth• RoHS compliant Features•Measures corrosion, temperature, and relative humidityon a continuous basis•Direct interface provided by the backlit LCDand keypad• Remote power from network cable (PoE)•4-20mA connection with existing facility managementsystems or distributed control systems (DCS)• AA battery-powered for remote or inaccessible areas• Provides incremental and cumulative corrosion data• Long service life• Accurate within ± 0.5-1% of full span Principle of OperationThe OG4 comes with two quartz crystal microbalance(QCM) sensors, one that is plated with copper and anoth-er with silver. The QCM is used to measure the corrosivefilm that results from the environment. This highly sensitivemethod of measurement will indicate contaminant levelsat or less than one part per billion (1 ppb). The corrosionfilm thickness is measured and recorded in Angstroms (Å).This measurement corresponds directly to ISA StandardS71.04-2013.

Best Deals from Corrosion Test Equipment

Emcor Rust Test

Get Price Quote

5 Piece (MOQ)

Features Measures the ability of a grease to protect a bearing against corrosion in the presence of water. Two sets of grease-coated bearings per station are partially immersed in water and rotated at a speed of 80 rpm in a sequence of running and resting periods. At end of the test, the raceways of the bearing outer rings are inspected for rust. Performs both standing and dynamic test of lubricating greases and oils. Capable of performing 4/6/8 tests at a time. Consisting of : Test rig with base plate, electric motor with gear and run/stop electronic timer, steel shaft, plummer blocks, self-aligning ball bearings, adapter sleeves, sleeve nuts and V-ring seals. Power supply 220 V, 1 Phase, 50 Hz

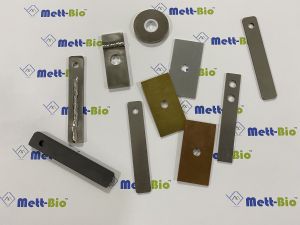

U Bend Corrosion Coupon

900 - 1,000 Per piece

100 Bag (MOQ)

Mett-Bio Metallurgical Testing and Analysis is an independent R&D division with ISO 17025:2017 (NABL) accreditation, located in Ahmedabad, India. is involved in corrosion testing and failure analysis since 2013. We are glad to announce Corrosion Test Coupons, an inexpensive online monitoring tool that will allow you to properly monitor corrosion within your systems. The mile per year corrosion rate of an exposed coupon can be used to easily determine the materials life. Mett-Bio can help you manufacture coupons in any shape, size, and material (ferrous, non-ferrous, and elastomeric). Depending on the requirements, a suitable marking can also be stencilled on the coupons. Typical coupon shapes include flat strip coupons, disc coupons, and cylinder coupons. Mett-Bio provides a variety of coupon holders and can also develop and manufacture custom holders to meet specific requirements.

Emcor Rust Test

Get Price Quote

Product Description Measures the ability of a grease to protect a bearing against corrosion in the presence of water. Two sets of grease-coated bearings per station are partially immersed in water and rotated at a speed of 80 rpm in a sequence of running and resting periods. At end of the test, the raceways of the bearing outer rings are inspected for rust.Performs both standing and dynamic test of lubricating greases and oils.Consisting of : Test rig with base plate, electric motor with gear and run/stop electronic timer, steel shaft, plummer blocks, self-aligning ball bearings, adapter sleeves, sleeve nuts and V-ring seals.Power supply 220 V, 1 Phase, 50 Hz

CORROSION TEST EQUIPMENTS

Get Price Quote

corrosion test equipment

Get Price Quote

Polypropylene based ,able to withstand stringent atmospheric conditions. • Fully-automatic operation with Software & temperature control. • On-board data logging and trending. • Adjustable baffle on central fog tower. • Pneumatic door lift for effortless operation

Static Corrosion Studies Devices

Get Price Quote

WP / WT°: 250 bar / 400 ° C Any type of static corrosion samples. Sour and non-sour media. Volume : 1 to 50 liters MOC: Stainless, Inconel, hastelloy, titanium... Optional stirring. Easy closure equipment. Control and Acquisition under Lab view. In compliance with PED 97/23 and any standard on requirement

corrosion test equipment

Get Price Quote

Corrosion testing is the major test method that helps to understand that how the material will behave when they are subjected to several rigorous conditions at the time of its usage and contributes to estimating the characteristics and actual working behavior of the materials. Corrosion testing helps the manufacturers to plan, predict and mitigate the adverse effects of corrosion that occurs in the materials when they are placed in opposite working environments. The testing machine is widely used to ensure that the materials and components are used to produce metal products will perform best in the planned and tested working environment and capable enough to survive for a longer period of time. The test is performed majorly on the various materials such as metals, steels, and alloys – ferrous and non-ferrous both to make the products rust proof.

Corrosion Test Equipment NACL

20,000 - 30,000 Per Piece

5 Piece (MOQ)

Pneumatic Valves, Drying Ovens, Pneumatic Accessories

corrosion testing equipment

Get Price Quote

corrosion testing equipment, Benchtop Temperature & Humidity Chambers

corrosion testing equipment

Get Price Quote

corrosion testing equipment

corrosion testing equipment

Get Price Quote

corrosion testing equipment, coal testing equipment, Rebound Hammer