Spares for corrugated board and box making machine

1,000 - 100,000 Per Set

1 Set(s) (MOQ)

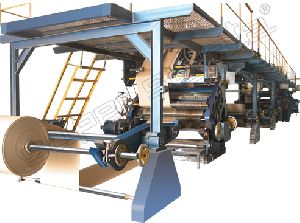

Automatic 3 & 5 Ply Paper Corrugated Board Making Plant

Get Price Quote

Our company holds expertise in manufacturing, exporting and supplying precision engineered Automatic 3&5 Ply Paper Corrugated Board Making Plant. Our Automatic 3&5 Ply Paper Corrugated Board Making Plant is a high speed bearing mounted corrugation machine with variable speed drive. It is designed using high grade components and modern technology in compliance with the set industrial norms. Our machine is widely acclaimed for high efficiency and production. Further, Automatic 3&5 Ply Paper Corrugated Board Making Plant comes in customized specifications to meet all industrial requirements.

Best Deals from Corrugated Board Making Plant

3 Ply Automatic corrugated board making plant

1,500,000 Per Piece

1 Piece (MOQ)

Corrugated Cardboard Making Plant

Get Price Quote

1800mm 5 Ply Automatic Corrugated Board Making Line

350,000 Per Set

1 Set (MOQ)

3/5 Ply Automatic Online Corrugated Board Making Plant

Get Price Quote

For corrugators, who want superior quality boards and higher production, on line 3/5 ply corrugated board making plants is the only solution. On line corrugated board making plants are ideal solution for achieving higher production capacity and superior board quality. Reduces production cost manifold. "SUPER SUJATA" offer ultra modern on line 3/5 ply paper corrugated board making plant. Assured quality with unmatched service back up. Specifications 5 ply corrugated box making plant High speed bearing mounted corrugation Machine with variable speed drive- 2 nos. Drum type heaters - 4 nos. Self loading reel stand- 5 nos. Triplex heating unit before gluing On line duplex pasting unit Heating cooling and drying chamber (consist of fourteen hot plates) Heavy duty pull unit On line creasing and slitting unit Heavy duty cut off unit 3 ply corrugated box making plant High speed bearing mounted corrugation Machine with variable speed drive Drum type heaters - 2 nos. Self loading reel stand- 3 nos. Duplex heating unit before gluing On line simplex pasting unit Heating cooling and drying chamber (consist of nine hot plates) Heavy duty pull unit On line creasing and slitting unit Heavy duty cut off unit The plants above include complete fabrication and synchronization of all machines together. Overhead bridge and conveyor take up belts. Motorized web adjustment unit, Gangway and stairs.

Corrugated Board Production Line Plant

15,000,000 - 45,000,000 Per Set

1 Piece (MOQ)

Corrugated Cardboard Production Line is the professional equipment for producing corrugated cardboard. The 3ply, 5ply, 7ply and multi-function corrugated cardboard production line mainly consist of the following equipment : Mill Roll Stand, surface paper (core-paper) pre-heater, single facer, Conveying Bridge, Glue Application Machine, Double Facer, Slitter Scorer, Cut-off, Conveyer and Stacker, Heating System, Air compression system and Glue Making System, etc. The 3ply, 5ply, 7ply, and multi-function corrugated cardboard production line has high middle and low grade with different-specifi cation and different-quality equipment. On the base of understanding the requirements of the customers and the advanced skills at home and abroad, our company has developed and designed these production lines with the speed 100-220m/min; the paper width 1400-2200mm and four fl uting UV type A, B, C, E for all the customers to choose from.

three ply automatic corrugated plant

47 Per Set

500 Set (MOQ)

Three ply automatic corrugated plant Adhesive plays a major role in Corrugated board Production and the Quality of the final products.The glue itself constitutes a very small proportion of the corrugated board, but has major impact on both the Productivity of the Corrugator and the Quality of the final board. Automatic corrugated plants run on steam and heat transfer to board is very good. So, they can use formulation based on native starch. But inconsistent viscosity of native starch causes to many problems and does not allow smooth running of Auto Plant. To overcome the problem, We have developed a formulation with water mix ratio (1:3) based on modified Starch with some additives. The Gum is carrier based formulation which gives Consistent Viscosity, High initial Tack, Quicker Gelling and rapid bond forming properties to enable the machines to run on desired speeds. ADVANTAGES - Uniform flow, Consistent Viscosity and no lump formation ensuring smooth application of Gum. - High Initial Tack & Quicker Gelling allow machine to run on designed speed which is important for formation of green bond. - Good Mileage and Low Consumption as compared to caustic based adhesives. - Better penetration to form deeper fiber-tearing bonds with minimal cure time - Excellent Bursting Strength (B.S) and Compression Strength (C.S). - Quick Setting, Superior Bonding & No Chance Of De-Lamination. - Fast drying time which ultimately results faster running speeds - resulting in higher production output. - Has low gelatinization temperature thus minimizing the energy consumption giving higher machine speed which ultimately results into greater production yield.

Automatic 05 ply corrugated board making plant - Premium Model

Get Price Quote

1 Set(s) (MOQ)

model: premium model plant length: 60+ mtr speed: 120-140 mtr/min heating type: electric / steam / thermic production capacity: 40+ ton/day.

Automatic 3 & 5 Ply Paper Corrugated Board Making Plant

Get Price Quote

5 Ply Inline Plant

Get Price Quote

We have a team of professionals who keep their vigil eyes on the entire lot that is stored in the warehouse. This unit keeps the lot free from the factors like duct, rain, sunlight, etc. We manufacture 5 Ply Inline Plant using optimum quality raw materials to make it highly reliable and efficient. Being a trustworthy Supplier in the market, we cater to the demands of the customers by presenting excellent 5 ply inline plant.

Automatic Board Making Plant

200,000 - 30,000,000 Per piece

1 piece (MOQ)

Ply Automatic Board Making Plant

Get Price Quote

1 Piece(s) (MOQ)

We are offering ply automatic board making plant. No. machine name qty remarks 1 mill roll stand 5 full hydraulic control, pneumatic control brake, cog-type top paper chuck 2 railing and track 10 include railing and track. 3 pre-heater (facer paper) 2 diameter 900mm,electric adjust wrapping angle 4 single facer 2 corrugating roll diameter 320mm, adopt 48crmo alloy steel, sizing agencies can remove, convenient maintenance 5 pre-conditioner 2 diameter 900mm 6 double layer bridge conveyer 1 frequency adjust wind adsorption, electric correct error 7 triplex pre-heater 1 diameter 900mm, electric adjust wrapping angle 8 gluing machine 1 gluing roll diameter 318mm, main bearing adopt imported nsk brand 9 double facer 1 heating plants 600mm×15set, surface do treated and chromed, pneumatic tension, hydraulic lift-down, include cotton belt 10 main drive 1 independent reducer box, gimbal driving. Corrugating roll diameter 768mm 11 thin blade slitter scorer 1 4 blade 6 score 12 nc cutting machine 1 adopt imported servo driver, paper cutting precision 1mm when the speed average 13 stacker 1 wide belt transmission cardboard 14 glue making system 1 include main pot 1 set, carrier pot 1 set, and storage pot 2set, include glue station pump, single facer glue pump and gluing machine glue pump. Circle supply glue, pipeline provided by customer 15 pneumatic system 1 include steam-water separator and gas storage pot, pipeline and air-compressor supply by customer. 16 electric system 1 whole line main motor frequency adjust speed, electrical adopt abb or schneider brand.

3 Ply Brown Corrugated Paper Boxes

8 Per Piece

500 Piece (MOQ)

corrugated board making plant

Get Price Quote

For corrugators, who want superior quality boards and higher production, on line 3/5 ply corrugated board making plants is the only solution. On line corrugated board making plants are ideal solution for achieving higher production capacity and superior board quality. Reduces production cost manifold. "SUPER SUJATA" offer ultra modern on line 3/5 ply paper corrugated board making plant. Assured quality with unmatched service back up.

corrugated board making plant

Get Price Quote

We are offering corrugated board making plant.

Online Corrugated Board Making Plant

Get Price Quote

3/5 Ply Fully Automatic Online Corrugated Board Making Plant Assopack offers complete range of 3/5 ply fully automatic online paper corrugated board making plant for higher speed starting from 100m\min to 300m/min or so on. Looking aspect of Industrial automation Assopack present for high production and less labor involve free machine for domestic and overseas market. With computerized control machines. Assopack offers Production Control System with whole line. In various deckle like starting from 1600mm,1800mm,2000mm,2200mm,2500mm and 2800mm. This is line is being imported from china,Taiwan or Japan. Completely with fingerless single facer machine further quality of board is unmatched achieve. On full turn key base. Accessories, bearing, belt and other related equipment are totally from Taiwan and Japan make.

3/5 Ply Automatic Corrugated Board Making Plant

Get Price Quote

We are offering high quality 35 Ply Automatic Corrugated Board Making Plant which is powerful with its unique construction. This plant is equipped with reel stands, unwinding shafts and brakes, take up units, belts, heaters, glue unit etc. Our product is widely used in packaging industries for quality packaging. We are offering this plant at an affordable market price.

Paper Corrugated Board Making Plant

Get Price Quote

Since 2001, Jaikar Industrial Corporation have been one of the prominent manufacturer of Industrial machinery. We have been supplying our 35 Ply Automatic Paper Corrugated Board Making Plant to our clients in various cities all over India especially in the Punjab where it is highly demanded. With the vision to be the No. 1 manufacturer of Industrial Machinery, we are continuously working on the quality of our production. We have strictly standardizes our production to match even the demands from International market. Specifications Higher productivity Better paper board quality Adoption of central control system Simple & easy operation and require lower degree of manpower Convenient to repair and maintenance Reliable and safe In our factory occupying 12,000 m2the manufacturing of 35 Ply Automatic Paper Corrugated Board Making Plant is done using modern technology to ensure precision in the products. Jaikar Industrial Corporation adopts the most updated source-saving mode which get heat from the high-temperature guiding oil compared with the steam heating it reduce the source by 60% so that cut the cost effectively. It is economical ideal product and suitable for big and medium carton manufacture. Jaikar Industrial Corporation manufacture 35 Ply Automatic Paper Corrugated Board Making Plant which aresuitable for large quantity automatized manufacturing. They can produce good quality corrugated cardboard which are no less than standards set to be used all over India. Salient features: Mill roll stand: the two holder can lift and lower independently. Drum type Pre Dryers increases drying capacity of the machine. Single facer: The diameter of the corrugating roll is 280 mm – 380 mm. Complete with Pneumatically controlled upper roll, pressure roll & gum rolls. Drying machine: Double baker is made of 17 pieces of heater plate. Pneumatic strain device and conveyor belt separate automatically once the power cut. Slitting machine: Slitter and Scorer is provided for online slitting & creasing of board. CNC Slitter & Scorer can also be provided. This production line is suitable for large quantity automatized manufacturing and it can produce good quality corrugated cardboard which can meet nationalize standard completely. Higher productivity, better paper board quality, adoption of central control system, simple and easy operation, convenient to repair and maintenance, reliable and safe, greatly lower degree of manpower requirement. This production line adopts the most updated source-saving mode which get heat from the high-temperature guiding oil compared with the steam heating it reduce the source by 60% so that cut the cost effectively. It is economical ideal product and suitable for big and medium carton manufacture.

corrugated board making plant

Get Price Quote