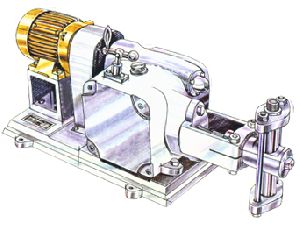

Mild Steel Cryogenic Pump

600,000 Per Piece

1 Piece (MOQ)

Cryogenic Liquid CO2 Cylinder Filling Pump

Get Price Quote

By keeping in mind the universally accepted market standards, we are exclusively engaged in offering CO2Cylinder Filling Pump. These reciprocating pumps are manufactured as per with the set norms of market & finest quality of components. Our offered reciprocating pumps can be availed in number of stipulations as per the variegated needs of patrons. Our quality checkers examined these reciprocating pumps on assorted parameters in order to assure its flawlessness. CO2 Cylinder Filling Pump come with the below enlisted features and specifications Optimum efficiency Precisely design Hassle-free functionality

Best Deals from Cryogenic Pumps

cryogenic pumps

Get Price Quote

Reciprocating Centrifugal Submerged

Cryo Pumps Cryogenic Pumps

32,000 Per Piece

1 Piece(s) (MOQ)

Global leader in development, engineering, manufacturing and testing of submerged motor cryogenic pumps for 30 years.nikkiso cryo, inc., is one of the world's foremost suppliers of submerged motor liquefied gas pumps, offering unmatched reliability, quality and safety.fixed in-tank pumps, suction vessel mounted pumps, removable in-tank pumps.

cryogenic pumps

1,200,000 - 1,300,000 Per cm2

Cryogenic pump

300,000 Per Piece

cryogenic pumps

Get Price Quote

Cryogenic Pumps Cryogenic pumps are designed to move coolants and cryogenic liquids. They are built to withstand and operate in extremely cold temperatures. Cryogenic pumps feature hermetically sealed designs to minimize heat leakage from the motor or contamination by process fluids into the cryogenic fluid. Long shaft cryogenic pumps are designed with the pump motor and mounting flange separated from the pump impeller by a long shaft. The pump impeller is submerged in the cryogen or freezing liquid. This minimizes the leaking of heat from the motor into the frozen or freezing cryogenic fluid. Long shaft cryogenic pumps may be welded or bolted to a variety of cryogenic equipment, including dewars and cryostats.

Cryogenic Vacuum Pump

Get Price Quote

FEATURES Pump range is available in nominal sizes from DN100 to DN1250 HSR design reduces cool-down times Higher cooling power, Higher capacity and superior performance on second stage Optimized design enables operation in process temperatures up to 3500◦C and high gas loads in the same time Low vibration cooling system Closed-circuit operation (No need for continuous gas supply) Patented geometry ensures outstanding up-times and short regeneration times Highest manufacturing quality Applications HSR Cryo-pumps are high vacuum pumps, renowned for providing clean and outstanding vacuum in a very reliable manner. They find extensive use in: Thin-film coating systems Space Simulation chambers Sputter equipment Fusion test systems Particle accelerators Thermal coating systems Metallizing equipment

cryo pumps

500,000 Per Piece

1 no (MOQ)

we are experts in re- buliding cryu pumps in india spares available for cryo pumps

cryogenic pumps

Get Price Quote

A Cryocooler is a standalone cooler, usually of table-top size. It is used to cool some particular application to cryogenic temperatures. A recent review is given by Radebaugh. The present article deals with various types of cryocoolers and is partly based on -------

Cryogenic Pump Skid for oxygen nitrogen argon co2

235,000 - 375,000 Per No

1 Number (MOQ)

Cylinder Filling pump for LIN LOX LAR 300 Nm3 per hour to 375 nm3 per hour

High Pressure Cryogenic Pump

Get Price Quote

With us, clients can stay assured for secure, safe and hassle free transactions. Our payment procedures are easy to use and guarantee confidentiality of the transaction. Our complete range of products is subjected to stringent quality tests to ensure they are as per norms of international management systems.

cryogenic pumps

Get Price Quote

Our range of sealless canned motor pumps are widely appreciated in various industries and plants like power, oil, gas, petroleum and chemical industries. These Sealless canned motor pumps are highly advantageous since it reduces the need of shaft seals and coupling. All these features significantly reduces the installation costs. We manufacture and supply these sealless canned motor pumps in standard specifications as per the industrial requirements. Customers can avail these sealless canned motor centrifugal pumps in different grades and in market leading prices.

UMHD Cryogenic Pump

100,000 Per unit

cryogenic pumps

Get Price Quote

CryoZone offers a range of cryogenic pumps specially designed to achieve heat transfer between an application and a cooler using a flow of liquid. Cryogenic challenges with a Cryogenic pump Through years of experience CryoZone has developed a lot of cryogenic knowledge. Especially regarding handling cold and delivering it to the customers’ application. This results in one of CryoZone’s leading edge products created and optimized for cryogenic liquid flow distribution. The CryoPump, also known as a cryogenic liquid pump, liquid nitrogen pump, cryogenic circulator or just cryogenic pump, will achieve efficient cold transport for cryogenic challenges. Cryogenic liquid pumps High efficiency flow for closed loop cooling systems CryoZone offers a range of liquid gas circulation pumps. The cryogenic circulators have been optimized for closed loop cooling systems. These cryogenic pumps are used to circulate a liquid gas in order to transport cooling power from a cold source into and through an application. Examples are superconducting cables and thermal shields in vacuum chambers or other (large) devices. The required cooling power usually comes from a cryogenic system using a cooling machine or bulk liquid. In either of these cases there is a limited budget of cooling power which makes the efficiency of the pump of the utmost importance. The efficiency of CryoZone's liquid gas pumps ranges from 30 to more than 50%, depending on the set-up of the closed loop system. Important factors are the required flow versus the pressure drop over the system. By balancing these at the system design phase, the total set-up can be optimized. Typical applications are closed loop cooling systems, or (LNG) spray pumps. If a standard Cryogenic liquid pump is not available, CryoZone is willing to discuss the possibilities for a custom design pump. Please contact us for more information. Downloads Cryogenic pump design - Coldfacts #31 June 2015

cryogenic pumps

Get Price Quote

Oxyplants India Pvt. Ltd. offers a full line of Cryogenic pumps for Oxygen/Nitrogen/Argon Liquid from the cryogenic tank is compressed to high pressure in a cryogenic liquid pump. It is then vaporised in an ambient air vaporiser to produce gaseous oxygen/Nitrogen/Argon. The high-pressure gas then can pass into cylinders via the gas manifold or fed into a customer's product pipeline.

Cryogenic pump

Get Price Quote

1 Set (MOQ)

CRYOGENIC VACUUM PUMPS

Get Price Quote

Cryogenic Vacuum pumps are high vacuum pumps which achieve said vacuum by entrapping gaseous substances on cold surfaces (cryo-panels). HSR AG’s cryogenic pumps are, amongst other things, known for their impeccable performance data and reliability in use. Long operating periods between necessary maintenance breaks provide for high availability as well as seamless and cost effective operation. FEATURES Pump range is available in nominal sizes from DN100 to DN1250 HSR design reduces cool-down times Higher cooling power, Higher capacity and superior performance on second stage Optimized design enables operation in process temperatures up to 3500◦C and high gas loads in the same time Low vibration cooling system Closed-circuit operation (No need for continuous gas supply) Patented geometry ensures outstanding up-times and short regeneration times Highest manufacturing quality Applications HSR Cryo-pumps are high vacuum pumps, renowned for providing clean and outstanding vacuum in a very reliable manner. They find extensive use in: Thin-film coating systems Space Simulation chambers Sputter equipment Fusion test systems Particle accelerators Thermal coating systems Metallizing equipment

Cryogenic pump

Get Price Quote

We are the main supplier of this product.

Cryogenic Reciprocating Pump

Get Price Quote

2 Piece (MOQ)

CRYOGENIC HIGH PRESSURE RECIPROCATING PLUNGER PUMP

Get Price Quote

SPECIAL FEATURES Extremely low NPSH requirement, only 0.1 to 0.5 Mtr Gland Packing specially developed for leak less operation, hence reduced product loss Indigenously developed, High Reliability Minimal Maintenance, all parts available off the shelf Quick Cold End Cool Down Designed for continuous operation Pump with variable capacity arrangement available for process control Available from 150 Kg/hr to 1500 Kg/hr - largest range available Prompt after Sales Service, assistance for erection, commissioning and operation

cryogenic pumps

Get Price Quote

Our Cryogenic pumps are manufactured using Swiss Technology. We offer the highest levels of safety for Oxygen service. We supply to all major industrial gas companies worldwide. Pumps need very low maintenance, and have high reliability. Worldwide after sales network 2000 pumps installed globally

Cryogenic Centrifugal Pump

Get Price Quote

cryogenic pumps

Get Price Quote

cryogenic pumps, Pump Spares

cryogenic pumps

Get Price Quote

We are offering a wide range of high quality cryogenic pumps from india.

cryogenic pumps

Get Price Quote

cryogenic pumps, Cryogenic Tanks, vaporizer vacuum pipe, Medical Accessories

Cryogenic pump

Get Price Quote

Cryogenic pump, Pumps, pumping equipment, oil field equipments

cryogenic pumps

Get Price Quote

We are a collaboration between Cryostar France & Cryopump Asia For 25 years, our factory has manufactured cryogenic pumps in India. Worldwide after sales network 2000 pumps installed globally

cryogenic pumps

Get Price Quote

cryogenic pumps, cryogenic equipment, cryostats cabinet, cryostats systems

Cryogenic pump

Get Price Quote

Cryogenic pump, vertical process pumps