Decanter Centrifuge

700,000 - 1,700,000 Per Unit

1 Unit (MOQ)

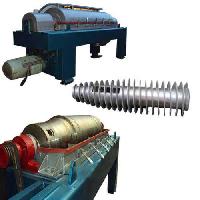

Industrial Decanter Centrifuge

1,000,000 Per Piece

1 Piece (MOQ)

Best Deals from Decanter Centrifuges

Drum Decanting System

Get Price Quote

Decanter Centrifuge

Get Price Quote

Our company has broaden its horizon by providing completely new and reconditioned conveyors for Decanters for customized products. These products are manufactured using high grade raw material in compliance with industry laid norms and guidelines.

NX418B-11G Reconditioned Decanter Centrifuge

Get Price Quote

Being a reliable name in this arena, we make sure that the payment procedures remain secured with us. In addition, we issue invoice to the clients stating all the relevant information of the products. We make sure that there will be no damage to the products that we deliver to the customers. For this, we use high quality packaging material and hi-tech machines ensuring the same.

Decanter Centrifuge

Get Price Quote

We are dedicatedly engaged in offering Decanter Centrifuge to our clients. It is extensively used in various industries for the separation of various types of mixtures. We offer it in various sizes and capacities, as per the client’s requirements. We are well-capacitated to furnish it in bulk quantities, within the promised time frame. It is highly accredited for its excellent performance, smooth functioning, and long working life. It is highly resistant to corrosion and heat. We offer it at the leading market rate.

Drum Decanting System

Get Price Quote

We are offering drum decanting system. A drum decanting unit, or ddu, is a mechanized and automated means to add drummed additives to the blending system. The mechanization of drum decanting promotes safety and resource utilization while decreasing blending variation and labor costs. The unit's automation simplifies recipe management and production planning while limiting waste generation.

Decanter Centrifuge

2,738,500 Per Piece

K-Pack Systems Pvt Ltd. We are a Bangalore based medium sized Indian company and have experience of more than 25 years in waste water treatment. We are active all over India as well as in Europe, Middle East and Africa. We are Water treatment Solution providers and OEMs of equipment like Dissolved Air Floatation systems, Lamellas, Clarifiers, Oil Water Separators (TPI, API, CFS), Pipe Flocculator, Oil Skimmers etc. We have done more than 2500 installations of such equipment. We have come up with a new equipment which supports all sludge generating systems, which efficiently separates solid sludge from liquid-solid slurry generated from above equipments. As these slurries are in two phases, industries need to separate these two phases for their easy handling. Therefore, Separation of Solids from liquids plays a key role in industrial processes. Decanter Centrifuges from K-pack perform this crucial operation very well. Virtually all types of industry need to separate solids from liquids for Effluent Treatment Plant (ETP) or Sewage Treatment Plant (STP) or Waste Water Treatment Plant (WWTP) or other processes. The Decanter Centrifuge is based on the simple idea of a clarifier or settling tank in which particles, sediment and solids gradually fall to the bottom due to the force of gravity. Decanter Centrifuge Technology uses high speed rotational centrifugal power, therefore replacing effect of gravity by a centrifugal force up to 4000 times more powerful. This force is then used to separate solids from liquids efficiently in a manner that is easy to control. A Decanter Centrifuge can be used to separate wide range of solids from liquids.

Decanter Centrifuge

1,400,000 Per Piece

Decanter Centrifuges

2,500,000 Per Unit

1 Piece (MOQ)

Decanter Centrifuges

100,000 - 2,500,000 Per Bag

In the realm of decanter centrifuges, Trity Environ Solutions stands out as a prominent manufacturer and supplier dedicated to delivering cutting-edge solutions for efficient separation processes. Specializing in the design and production of high-performance decanter centrifuges, Trity Environ Solutions has positioned itself at the forefront of technological innovation. Their commitment to quality engineering and use of state-of-the-art materials ensures the creation of robust machines capable of meeting the diverse needs of industries such as wastewater treatment, oil and gas, food and beverage, and pharmaceuticals. As a trusted supplier, Trity Environ Solutions acts as a vital link, connecting these advanced technologies with end-users, facilitating the seamless integration of their decanter centrifuge systems into various applications. In an era where environmental considerations are paramount, Trity Environ Solutions plays a pivotal role in providing sustainable and energy-efficient solutions to address the evolving demands of the global market.

Decanter Centrifuge

Get Price Quote

Based on the principle of sedimentation, the Decanter Centrifuge Machine uses the force developed under fast rotation of a helical screw conveyor which separates the liquid from the solid fraction at a slightly higher or lower speed than the bowl.Often the solids are too fine to be dewatered satisfactorily in the filtering centrifuges. They can be separated in solid bowl centrifuges provided their sedimentation speed in the mother liquid is sufficient. The sinking settling speed is determined by Particle size, Particle shape and difference in density between solids and liquids as well as their viscosity. In Decanter Centrifuges the cleaning of liquid takes place in cylindrical part where as dewatering of solids by compression of the filter cake takes place in conical part of the bowl. The geometry of the bowl, relation with length and diameter to be adapted to suit the application.The system is continuous, compact and enclosed while offering versatility, high performance, and low maintenance.The Decanters / Solid Bowl Centrifuges are used for clarification (liquid / solid separations), dewatering and classification duties in various process industries. Salient Feature : Co-Current design Simple, rugged construction Tow - three-phase separation process Rotor comprising screw conveyor inside conical/cyinderical bowl Screw conveyor (single flight or multiple flights), with or without hard surfacing Conveyor and bowl in various stainless steel : SS 304 , SS 316/316 L Solids discharge through collecting channel and hard-surfaced scrapers Wear protection of conveyor flights in tungsten carbide Wear protection (interchange able ) of conveyor systems Drive by electric motor and V-belt with gear box for high strength and reliability Oil lubrication for gear box and greasing for bearings Overload protection device Fixed differential speed variation War protection including inter changeable tungsten carbide tiles Automatic differential speed variation on request Vibration dampers Operation System : Separation takes place in Horizontal conical / cylindrical bowl with screw conveyor. The slurry in feed into the bowl through a staationery inlet tube and accelerated by specially design inlet distributor. Centrifugal force leads to instant sedimentations of the solids on the wall of bowl. The conveyor , rotating in the same direction as with differential speed, conveys the solids to conical end. The solids are lifted clear of the liquid and centrifugally dewatered before being discharged into the collecting channel. The clarified liquid flows into the housing through opening in cylindrical end of the bowl. Typical Applications : Treatment and disposal processes of sludge form municipal and industrial waste water Drying of animal slurry Inorganic products aluminum hydroxide, barium sulphate, lead oxide, chromium oxide ferrous hydroxide, magnesium hydroxide, titanium dioxide, zinc sulphate, etc. Organic products carboxymet hylcellulose, caprolactam, dimethylterephthalate, terephthalic acid, phthalic acid, etc. Plastics carboxymethycellulose, caprolactam, dimethylterphthalate, terephathalic acid phthalic acid, etc. Silicates asbstos , clay, etc. Cellulose de-inking flotation concentrate. Foodstuffs fishmeal, casein, whey, etc.

Decanter Centrifuge

Get Price Quote

Keeping in mind the ever-evolving requirements of our clients, we are devoted towards supplying an optimum quality Decanter Centrifuge. This device is designed and manufactured at our vendors' manufacturing unit using the outstanding quality raw material and latest technology following the international industry standards. These are used in sewage treatment plants, waste water treatment plants, and plastic industries in order to separate the solid and liquid particles in the slurry. They are known for their features like high quality, durability, and resistance to corrosion. To get the total satisfaction of the customers, we provide this product at the most affordable price.

Decanter Centrifuge

200,000 Per Piece

horizontal decanter centrifuge

1,000,000 - 5,000,000 Per Piece

01 Piece(s) (MOQ)

The solid phase particle size 0.005 ~ 15 mm, 1 ~ 40% concentration, temperature < 100 ℃ of all kinds of slurry solid phase dehydration, clear separation of liquid phase, sizing, etc. Especially suitable for regeneration of filter cloth have difficulty bigger suspending liquid separation and concentration, particle size change.

basket type decanter Centrifuge

180,000 - 1,250,000 Per set

1.0 Set (MOQ)

Decanter Centrifuge

Get Price Quote

Application :The Decanters / Solid Bowl Centrifuges are used for clarification (liquid / solid separations), dewatering and classification duties in various process industries.Typical Products Processed : Inorganic products: Aluminium hydroxide, barium sulphate, lead oxide,chromium oxide, ferrous hydroxide, magnesium hydroxide, titanium dioxide, zinc sulphate, etc. Organic products: Carboxymethylcellulose, caprolactam, dimethylterephthalate, terephthalic acid, phthalic acid, etc. Plastics: Carboxymethycellulose, caprolactam, dimethylterephthalate, terephthalic acid, phthalic acid, etc. Silicates: Asbestos, clay, etc. Cellulose: De-inking flotation concentrate Foodstuffs: Fishmeal, casein, whey, etc. Design Features : Simple, rugged construction Rotor comprising screw conveyor inside conical / cylindrical bowl Screw conveyor (single flight or multiple flights), with or without hard surfacing Solids discharge through collecting channel and hard-surfaced scrapers Drive by electric motor and V-belts with gear box for high strength and reliability Oil lubrication for gear box and greasing for bearings Overload protection device Vibration dampers Optional Gas-tight design with gas-sealed labyrinths Perbunan, viton or PTFE seals Pressure-tight design with glide ring seals for up to 10 bar Optional – Centralised lubrication System Operations : Separation takes place in Horizontal conical / cylindrical bowl with screw conveyor. The slurry is feed into the bowl through a stationery inlet tube and accelerated by specially design inlet distributor. Centrifugal force leads to instant sedimentation of the solids on the wall of bowl The conveyor, rotating in the same direction as bowl with differential speed, conveys the solids to conical end. The solids are lifted clear of the liquid and centrifugally dewatered before being discharged into the collecting channel. The clarified liquid flows into the housing through opening in cylindrical end of the bowl.

Decanter Centrifuge

Get Price Quote

Decanter Centrifuges

1,500,000 Per Piece

Decanter Centrifuges

Get Price Quote

Decanter Centrifuge

Get Price Quote

We offer Decanter Centrifuge. Decanter Centrifuge ESS-1967HD2 Barite Recovery & Dewatering Centrifuge Whether you are working toward maximizing barite recovery or looking to get the most out of your “zero-discharge” closed-loop system, Elgin’s field proven decanter centrifuges are a perfect choice. With over 500 centrifuges installed worldwide, the ESS-1967HD2 represents Elgin’s flagship decanter centrifuge. Power and Performance Elgin’s ESS-1967HD2 Decanter Centrifuge is fitted with a NEMA premium, continuous duty, energy-efficient, poly-chain driven, 125 hp main drive and a direct-coupled 40 hp back-drive. The 125 hp main drive can operate the centrifuge up to a maximum rotational speed of 3,100 rpm, therefore generating more than 2,500 G’s of force. Using an inclined motor mount, motor and belt maintenance is made easy by the adjustment of two jack screws. No additional motor mounts, brackets or tensioning devices are required. By utilizing a carbon fiber poly-chain, no belt retensioning is required after installation is complete. The carbon fiber tensile cords are length-stable and can withstand shock loads that frequently lead to belt failure. More importantly, Elgin’s carbon fiber poly-chain will not require quarterly replacement.

Industrial Decanter Centrifuge

200,000 Per Piece

Decanter Centrifuges

Get Price Quote

Alfa laval reconditioned tested decanter machine is available with us with 10 hp to 50 hp electrical motors. All machines comes with refurbishment work and running trails is also possible at our works.

Marine Decanter Centrifuges

Get Price Quote

With well-connected and substantial warehouse, we arrange the extensive range systematically to deal with urgent deliveries and orders. Our remarkably superior warehouse system helps us in keeping the range safe until the final send off. We will not let you wait much, as we have trustworthy shipping facilities available to deliver the same in set time. Available Make : Alfa Laval - NX 309 NX 418 Westfalia - CA 220 CA 366 Mitsubishi - KVZ 25 ML KVZ 35 ML Penwalt- P 3400 P 3000 Sharples - JPU 7963

Decanter Centrifuge

Get Price Quote

Decanter Centrifuges

100,000 Per Unit

Decanter Centrifuge

Get Price Quote

We are main supplier of this product.

Hydraulic Bitumen Decanter

17,500,000 Per Units

Drum Decanting System

400,000 Per Piece

Decanter Solid Bowl Centrifuge

Get Price Quote

We are offering decanter solid bowl centrifuge based on the principle of sedimentation, the decanter solid bowl centrifuge uses the force developed under fast rotation of a helical screw conveyor which separates the liquid from the solid fraction at a slightly higher or lower speed than the bowl. Often the solids are too fine to be dewatered satisfactorily in the filtering centrifuges. They can be separated in solid bowl centrifuges provided their sedimentation speed in the mother liquid is sufficient. The sinking settling speed is determined by particle size, particle shape and difference in density between solids and liquids as well as their viscosity. In decanter centrifuges the cleaning of liquid takes place in cylindrical part where as dewatering of solids by compression of the filter cake takes place in conical part of the bowl. The geometry of the bowl, relation with length and diameter to be adapted to suit the application. In most of the cases, good results are obtained at length diameter 2 : 1 and sometime depending upon application 2.5 3 : 1. The system is continuous, compact and enclosed while offering versatility, high performance, and low maintenance.