Sterilization And Depyrogenation Tunnel

Get Price Quote

1 Unit (MOQ)

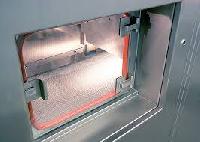

Sterilization and Depyrogenation Tunnels Depyrogenation tunnels, also known as dry heat sterilization tunnels or hot air tunnels, are specialized equipment used in the pharmaceutical and biotechnology industries to remove pyrogens from vials, ampoules, and other containers used in the manufacturing of sterile products. Depyrogenation Tunnels | Sterilization Tunnels Manufacturer and Exporter in India Depyrogenation tunnels, also known as dry heat sterilization tunnels or hot air tunnels, are specialized equipment used in the pharmaceutical and biotechnology industries to remove pyrogens from vials, ampoules, and other containers used in the manufacturing of sterile products. Sterilization and Depyrogenation Tunnel by Harikrushna Machines Pvt. Ltd. Harikrushna Machines offers state-of-art Pharmaceutical Sterilization & Depyrogenation Tunnel for drying, sterilization & depyrogenation of glass containers such as ampoules, vials, injection and infusion bottles, cartridges or syringes. Key Features and Principles: High Temperature: Controlled Airflow: Conveyor System: Validation: Monitoring and Control: Materials Compatibility: Tunnel for drying, sterilization and depyrogenation Harikrushna Machines Pvt. Ltd. offers a diverse array of sterilization tunnels, delivering versatile solutions for the efficient and sustainable treatment of various glass container types. Utilizing dry heat sterilization enables you to attain consistent treatment quality while optimizing energy consumption. Whether you are packaging liquid pharmaceuticals into ampoules, vials, injection and infusion bottles, cartridges, or syringes, ensuring the dependable sterilization of containers plays a crucial role in enhancing product safety. Vial Sterilization Tunnel: A vial sterilization tunnel is a specialized piece of equipment used in pharmaceutical manufacturing. It ensure the sterility of vials before they are filled with drugs or other sterile substances. This tunnel employs a controlled environment, typically utilizing dry heat or other sterilization methods. To eliminate or reduce microbial contaminants, ensuring the integrity and safety of the final pharmaceutical product.

Depyrogenation Tunnels

Get Price Quote

The Sterilization Depyrogenation cycle is based on selection of cycle times and exposure of temperature that will sterilize or depyrogenate the glassware to an acceptable low probability level of contamination, without adversely affecting the critical parameters of the product. Generally Heat destroys micro organisms. The destruction process of microorganisms is a function of time and temperature. The rate of destruction is linear logarithmic, means in a given time interval and at a given temperature, the same percentage of the bacterial population will be destroyed. Hence forth introduce “Forced Conventional Dry Heat Sterilizer” (Sterilizing Tunnel).

Best Deals from Depyrogenation Tunnels

Depyrogenation Tunnels

Get Price Quote

Detail Description Understanding the requirements of the clients, we are manufacturing a wide gamut of Air Sterilizer and Depyrogenation Tunnel for Ampoule, which are fabricated in compliance with CGMP design criteria. The "Hot Air Laminar Flow Principle" ensures gentle sterilization with a minimum of space and constant temperature of the Ampoule / Vial, perfect sterilization, short sterilizing times and high capacity. Salient Features Smooth breakage–free transportation is provided by means of the transport control which is regulated by the output of the preceding machine and the intake of the following machine. Sterilizing conditions are documented and are reproducible. Temperature is monitored and controlled electronically through PLC. Multiple layer insulation of the tunnel prevents heat loss, keeping energy consumption low. The belt speed and temperature can be programmed precisely and can therefore be optimized to suit to any kind of Ampoule/Vial. The machine is simple to operate from the central operating panel. All data relevant to production can be called up on the display. Technical Specifications The "Hot Air Laminar Flow Principle" ensures gentle sterilization with a minimum of space and constant temperature of the Ampoule/Vial, perfect sterilization, short sterilizing times and high capacity. Circulating airflow is constantly kept free of particles by means of a High-Efficiency Particulate Air (HEPA) filter. Range of product Sterilizing: 1ml to 25ml Ampoules / 2ml to 250ml Vials. Machine is suitable as a standalone & for Integration into a production line. DQ, IQ and OQ Documents for Machine. Get In Touch

Sterilsation And Depyrogenation Tunnel

Get Price Quote

Depyrogenation tunnels is designed to sterilize and depyrogenate glass containers The process is done maintaining and ISO 5 environment along the whole length and width of the conveyor belt complying with ISO 14644-1 requirements , they are designed to allow higher output in a more compact body with better control of the process parameters. Salient features of Sterlization and Depyrogenation Tunnel Each independent filter plenum is provided with filer integrity sample port The equipments conveyor belt is monitored and alarm stats is activated if it operates outside the belt speed set points Provision for ports to allow introduction of Validation thermocouples in each zone The tunnel is provided with full integrated vial flow control logic to allow automatic stops and restarts of the equipment. All filter modules have differential pressure gauges to mointor pressure. Pressure switches with high and low alarms. When the tunnel is not in use it can be operated in night -mode to save energy while preventing contaminations.

Sterilizing and Depyrogenation Tunnel

Get Price Quote

Each independent filter plenum is provided with filter integrity sample ports. The equipment’s conveyor belt is monitored and alarm status is activated if it operates outside the belt speed set points. Provision for ports to allow introduction of validation thermocouples in each zone. The tunnel is provided with fully integrated ampoule / vial flow control logic to allow automatic stops and restarts of the equipment. All filter modules have differential pressure gauges to monitor pressure. Pressure switches with high and low alarms When the tunnel is not in use it can be operated in night-mode to save energy while preventing contamination.

Depyrogenation Tunnels

Get Price Quote

The ‘Global and Asia Depyrogenation Tunnels Market’ will reach xxx Million USD in 2017. Global and Asia Depyrogenation Tunnels Market report begins from overview of industry Chain structure, and describes industry environment, then analyses industry size and forecast of Depyrogenation Tunnels by product, region and application, in addition, this Depyrogenation Tunnels research report introduces market competition situation among the top companies and company profile, besides, market price analysis and value chain features are covered in this report. Global and Asia Depyrogenation Tunnels industry report contains Analysis 2013-2017 and Forecast 2018-2023.

Sterilizing and Depyrogenation Tunnel

Get Price Quote

Features Each independent filter plenum is provided with filter integrity sample ports. The equipment’s conveyor belt is monitored and alarm status is activated if it operates outside the belt speed set points. Provision for ports to allow introduction of validation thermocouples in each zone. The tunnel is provided with fully integrated ampoule / vial flow control logic to allow automatic stops and restarts of the equipment. All filter modules have differential pressure gauges to monitor pressure. Pressure switches with high and low alarms When the tunnel is not in use it can be operated in night-mode to save energy while preventing contamination. ation Tunnel

Depyrogenation Tunnels

Get Price Quote

Depyrogenation Tunnels

Get Price Quote

Global Depyrogenation Tunnels Market Analysis Report studies latest Depyrogenation Tunnels industry trends, development aspects, market gains and Depyrogenation Tunnels industry scenario during the forecast period (2018-2023). The fundamental overview of Depyrogenation Tunnels industry, key market segments, product description, Depyrogenation Tunnels applications are presented in this report. Global Depyrogenation Tunnels Market report provides the details related to fundamental Depyrogenation Tunnels overview, development status, technological advancements, market dominance and market dynamics. The past data pertaining to Depyrogenation Tunnels industry along with present and forecast market scenario will drive useful business decisions.

Depyrogenation Tunnels

Get Price Quote

Each independent filter plenum is provided with filter integrity sample ports. The equipment’s conveyor belt is monitored and alarm status is activated if it operates outside the belt speed set points. Provision for ports to allow introduction of validation thermocouples in each zone.

Sterlization and Depyrogenation Tunnel

Get Price Quote

Depyrogenation tunnels is designed to sterilize and depyrogenate glass containers The process is done maintaining and ISO 5 environment along the whole length and width of the conveyor belt complying with ISO 14644-1 requirements , they are designed to allow higher output in a more compact body with better control of the process parameters. Salient features: 1. Each independent filter plenum is provided with filer integrity sample port 2. The equipments conveyor belt is monitored and alarm stats is activated if it operates outside the belt speed set points 3. Provision for ports to allow introduction of Validation thermocouples in each zone 4. The tunnel is provided with full integrated vial flow control logic to allow automatic stops and restarts of the equipment. 5. All filter modules have differential pressure gauges to mointor pressure. Pressure switches with high and low alarms. 6. when the tunnel is not in use it can be operated in night -mode to save energy while preventing contaminations.

Depyrogenation Tunnel

Get Price Quote

We are one of the famous manufacturers, suppliers and exporters of a wide range of Depyrogenation Tunnel We are engaged in providing various types of Pharmaceutical Depyrogenation Tunnels, which are used in food & beverages, cosmetics, pharmaceutical and industries across the country. As per FDA Norms and cG.M.P parameters, our tunnel is specially designed. This completely automatic tunnel has PLC and printer online. The Tunnel is comprised of fine units: The cooling zoneThe stabilizing zoneThe infeed drying zoneThe control panelThe sterilizing zone The infeed drying zone:Between vial washing and sterilizing chamber, the drying zone creates thermal barrier to protect the vials from contamination and pre heat the vials. For some hot air, the pressure difference is adjusted to flow from sterilizing zone to drying zone. Hence, drying and pre heating of the vials take place. The sterilizing zone:Up to temperature of 350 Degree C, the sterilizing zone can be heated. Heat is generated with the help of Incoly DS material heating elements. The function of the air temperature and air velocity is sterilizing time of the vials. The air velocity can be adjusted. To obtain a Log-3 pyrogen reduction, the thermal cycle is designed. The cooling zone:Vials enter into cooling zone from sterilizing zone where they are subjected to cold laminar air for lowering the room temperature. Through exhaust blower fitted down the belt, the hot air can be exhausted. The stabilizing zone:To maintain negative pressure in washing room and filling room, the stabilizing zone with cold laminar air flow stabilizing zone is used The control panel:The Control panel is completely automatic and has Printer On Line and PLC with Sterilizing Temperature Indication. For higher thermal efficiency & power saving, thyristoristed temperature control unit is used. Model: With belt width 300mm, 450 mm,600 mm, 750 mm , 900 mm & 1200mm. Output capacity: 90-300 vials/min 100-300 Ampoules Min 60-100 Bottles / Min as per Bottle size Application: Pharmaceuticals,Food,Chemicals Industries salient Features: *Stericlean hot laminar flow sterilization tunnel used for on line sterilization & depyrogenation for washed vials & ampoules, *class-100 laminar air flow Throughout drying, sterilizing, cooling & stabilizing zone. *Thyristorised temperature control for excellent power saving & thermal efficiency with uniform temperature in hot zone. * Automatic control through IC and on line printing

Sterilizing and Depyrogenation Tunnel

Get Price Quote

Salient Features Each independent filter plenum is provided with filter integrity sample ports. The equipment’s conveyor belt is monitored and alarm status is activated if it operates outside the belt speed set points. Provision for ports to allow introduction of validation thermocouples in each zone. The tunnel is provided with fully integrated ampoule / vial flow control logic to allow automatic stops and restarts of the equipment. All filter modules have differential pressure gauges to monitor pressure. Pressure switches with high and low alarms When the tunnel is not in use it can be operated in night-mode to save energy while preventing contamination.

Depyrogenation Tunnels

Get Price Quote

Depyrogenation Tunnels, Air Showers, Garment Cubicle, Laminar Air Flow Unit

Depyrogenation Tunnels

Get Price Quote

Depyrogenation Tunnels, tilting device, Co Mill, Capsule Sorter Machine

Depyrogenation Tunnels

Get Price Quote

Depyrogenation Tunnels, Slip Rings, Stoppering Machine

Sterilization & Depyrogenation Tunnel

Get Price Quote

Sterilization & Depyrogenation Tunnel, ROTOCONE VACUUM DRYER

Sterilization and Depyrogenation Tunnels

Get Price Quote

Sterilization and Depyrogenation Tunnels, Depyrogenation Tunnels