Paraflat Diamond Lapping and Polishing Machine

Get Price Quote

paraflat single side lapping machines with top plate / loading table movement up and down pneumatically. diamond lapping and polishing machine with copper plate and cast iron lap plate .

diamond polishing mill

Get Price Quote

1 Piece (MOQ)

Best Deals from Diamond Polishing Machine

diamond polishing mill

Get Price Quote

100 Carat (MOQ)

Atharva International Trade are manufacture of CVD diamond from 0.1 ct to 15 ct sizes in D to M color and VVS to I clarity. IGI certified stones available. We'r providing galaxy planning, laser cutting and polishing job work services at Surat Gujarat. We're exporting polished diamonds to various countries.

Diamond Grinding Glass Polishing Machine

85,000 Per Piece

1 Piece (MOQ)

Diamond Policing Machine

30,000 Per Piece

Diamond Granite Polishing Machine

1,080,000 Per Piece

Diamond Polishing Machine

20,000 - 30,000 Per

1 piece (MOQ)

8 Inch Lapidary Cabbing Machine

Get Price Quote

1 Piece (MOQ)

FEATURES OF CABBING MACHINE: The 8” model of cabbing machine is backed by a 1 HP strong motor. The direct-drive, single shaft motor comes with thermal protected ball bearing and copper windings. It’s designed by our team of technicians for heavy-duty grinding. This ensures long-lasting potentiality of the machine. The base of the machine is made of cast Aluminium. It’s durable, sturdy and adds sufficient weight to the machine, which is important to keep it steady and well-balanced while operating. The machine sits on a solid wooden board which is water-proof. This ensures it does not get deformed due to prolonged exposure to water. It further helps to maintain the stability of the machine. The spacing between the lapidary wheels is ample to establish a comfortable working area to perform cabbing on larger stones as well. This allows you to use even side rims of the wheels without any hindrance. The stainless steel hood on the top of the cab machine can be easily raised for inspection, easy mounting/unmounting of wheels, and cleaning, as per your convenience. The left shaft of the machine utilises 2 Hard Diamond wheels ( #100, #260 grits) and 1 Soft Resin Bond wheel (#260) which is the coarsest among other Resin Wheels. The right side shaft of the machine utilises 3 Soft Resin bond wheels (#600, #1200, #3000 grits.) An ideal sequence of wheels is achieved with this placement for the cabbing process. It allows you to begin and move from the leftmost wheel for grinding to the next wheel on right for finer process of grinding and polishing. The shaft is tapped for ½”-20 at both ends to house spin-on polish heads, aluminium laps, diamond facet laps, polish pads, etc. These laps can be mounted by removing the side covers at the ends and then utilise the laps according to your convenience. The cabbing machine consists of a 1” versatile shaft which can accept a variety of 1” arbor hole size wheels such as silicon carbide, diamond wheels, or rubber expandable drums, as per your utility. The stainless steel side covers are removable to allow usage of a polishing lap or a felt polishing pad and for easy cleaning and maintenance of the cab machine. It has an adjustable drip water system with shut off valves made of Brass to control the flow of water on the wheels. This ensures that the process of cutting cabochons is smooth and avoids overheating of the wheels. It also has a systemised drainage system to eliminate the accumulation of draining water in the machine. It comes with an in-built adjustable bright LED lamp for optimum vision during cutting and polishing gemstones. The speed of the motor is at a steady 1425 RPM, which is an ideal speed required for cutting fine and accurate stone cabochons. The edges of the base of the machine are covered with soft pipes. They serve as hand rests while working. This ensures your cabbing experience is pleasant and comfortable. ADVANTAGES OVER OTHER CAB MACHINES: Use of materials like cast aluminum for the base, stainless steel for the hood, and Water-proof wood for the board ensure that our cabbing machine is heavy-duty, lasts long, needs little maintenance and is a valuable investment. Most other machines resort to using a plastic base that isn’t as sturdy and prone to damage or have particle boards that are not water-proof and deform easily on prolonged exposure to water. The 8” model of our cabbing machine comes with a 1 HP heavy-duty motor as compared to a ¾ HP on most other machines, which means a more powerful engine for consistent operations and lasting results. An added advantage of the motor engine is that it’s a direct-drive motor which means it doesn’t have pulleys or belts to facilitate rotation of wheels. This means that you can apply force on the wheels while cabbing without slowing them down. The machine is almost silent while running. It makes your experience more enjoyable and less annoying. It comes equipped with one of the best diamond wheels in the industry that are trusted and loved by many across the world. It’s priced competitively and is considerably cheaper than similar machines in the market. It proves to be a valuable investment cabbing machine which ensures superior quality results for cabbing. The water valves are made of high-quality brass. This makes them last long and not clog easily. It is an easy-to-use, maintain, and convenient cabbing machine as it is rust free and requires least effort to clean the machine. This makes it an ideal choice whether you’re an amateur, a hobbyist, or a master of the technique. The submersible water pump provided with the machine is a mute pump which ensures that your concentration is not interfered with unnecessary noises while cabbing. All the necessary accessories that are required for smooth functioning of your work are provided with the cab machine. It is a fully set-up machine, which means you don’t have to worry about manually changing and swapping between diamond and resin-bond wheels for effortless cabbing of cabochon gemstones. SPECIFICATIONS: Height x Width x Depth: 15” X 43” X 20” Motor spindle speed: 1425 RPM Motor HP: 1 HP Wheel diameter: 8” Lap diameter: 6” Electric Supply: 220 volts, 110 volts Net weight: 55 Kg WHAT’S INCLUDED? 1 X Direct-drive, single-shaft Motor 1 HP 2 X Hard Diamond Wheels 8” X 2” 4 X Soft Resin Bond Diamond Wheels 8” X 2” 1 X Diamond Lap 6” 1 X Adjustable LED light 1 X Submersible Water Pump 2 X Water Pipe to connect the pump with the machine 8 X Brass Valve (6 at the front for the wheels, 2 at the back for side laps) 2 X Drainage pipe 8 X Aluminum Spacers 1 X Tool kit (Spanners, Screwdriver, Nuts & Bolts) WORKING OF CABBING MACHINE: Ensure that the wheels have been mounted in the correct sequence from left to right. We advise coarser wheels on the left and finer ones on the right. Place the pump in a bucket with clean water, connect its pipes to the cab machine and turn it on. Attach the drainage pipes to the machine with one end on the openings on the back of the machine and another end in a separate empty bucket to collect drainage water. You may choose to recycle the same water by using a common bucket for pump and drainage. It’s advised to mount the stone on a dop stick for safety (especially for smaller pieces). However, you may choose to keep the stone in hand if you are experienced or the piece is large enough for cabbing. Turn on the motor and start grinding the cabochon gemstone on the leftmost/coarsest hard wheel. Turn on the water supply for the wheel using the valve on top if required. It’s advised to wear an apron while working to avoid getting drenched in water. Use the adjustable LED light for better visibility if required. Keep checking the stone cabochon intermittently to monitor its shape and polish. Now move to the less coarse hard or a soft wheel for finer grinding and repeat the process. Once done with grinding, move further right to the finer soft wheels for polishing the stone. WARRANTY & SUPPORT: 1-year manufacturer warranty (Does not include physical damage and consumables). Installation and operation support. Drop us an email at sales@jewelsntools.com or contact us from the website for any assistance. We’d be quick to respond and glad to help. SHIPPING INFORMATION: Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched. The shipping of our cabbing machine is insured. The machine ships from India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

Diamond Polishing Machine

130,000 Per Piece

Diamond Polishing Machine

65,000 Per Units

10 Units (MOQ)

Diamond Polishing Machine

Get Price Quote

India accounts for nearly 80-90% of diamonds polished in the world. CG has been closely associated with the diamond polishing industry for over two decades. We have been supplying single as well as three phase induction motors in rolled steel shell and cast iron body construction to equipment manufacturers for diamond cutting and polishing industry. These include Capacitor Start Capacitor Run (CSCR), Capacitor Start Induction Run (CSIR), Permanent Split Capacitor (PSC) and Split Phase in single-phase category. We supply both reversible as well as non-reversible motors against specifications of the equipment manufacturer.

floor diamond polishing machine

65,000 Per Piece

1 Piece (MOQ)

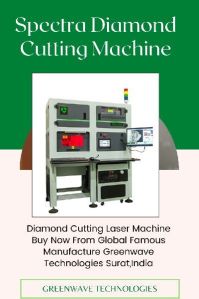

Laser Diamond Machine For Polishing & Cutting

Get Price Quote

SPECIAL FEATURES Laser Diode Source with GREEN Laser. Low Maintenances sealed, Long life pump diodes. Computer controlled all the laser commands with the help of software. BANDING FEATURES R.F. attenuation system with constant/stable Amp(I) to maintain diod life. Auto Image and parameters capture. "AUTO DEPTH"- Two Side sawing - Two Side sawing. Next to "NIL" breakage ratio. Smooth cutting surface. 40-50% less weight loss than any IR Laser. Eliminates diamond breakage & damage to a great extent by reducing unwanted internal reflections and internal focusing.

Diamond Polishing Machine

Get Price Quote

Diamond Die Polishing Machine

Get Price Quote

Pure Diamond Polishing Machine

Get Price Quote

Diamond Polishing Machine

Get Price Quote

Diamond Polishing Machine

37,159 Per Piece

1 Piece (MOQ)

diamond polishing mill

Get Price Quote

Diamond polishing mill, Metal and Concrete mill. Vibration-free operation, complete with metal frame, table top, 2 pok irons, 220/380V, 3/4 h/p, 1410rpm motor, two 20w light, 900X30 mm nylon belt, all electrical supplies

diamond polishing mill

Get Price Quote

Direct drive spindle eliminates source of vibration.. Solid cast iron body. Easy scaife leveling. available in small & BIG height with 1,2 & 4 Seat. Available in Complete with Dust collection system.