Pressure Vessels

Get Price Quote

1 Piece(s) (MOQ)

Frp pressure vessels are manufactured by high performance composite material with filament winding pressure vessels can be used practically for any water treatment application.

Gravity die casting

250 - 310 Per kg

50 Piece (MOQ)

Best Deals from Die Cast Components

Aluminium Die Casting

Get Price Quote

We provide Aluminium Die Casting that offers the desired performance for a long time due to its accurate dimensions, improvised design and use of high grade aluminium metal. The quality brought forth in this range makes our aluminium die casting a highly appreciated product amongst the clientele that we cater to.

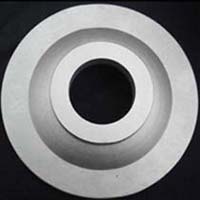

Continious Casting Dies

10,000 - 40,000 Per Piece

5 Piece (MOQ)

Continuous Casting Dies Manufacturer Cavity Moulds manufacture and supply the best quality of the Graphite Continuous Casting Dies. Our products are formulated with the help of the right chemical composition. We are getting broad appreciation from customers for the products best quality and their features. These are enormously valued among the clients for their durability, corrosion & rust resistance, compact designs, low maintenance and longer service life. Continuous casting dies is supposed to be trustworthy casting procedure for the manufacturing of the best quality semi-finished products from ferrous and non-ferrous alloys. In the regular casting, liquid metal is endlessly poured into an unlimited cooled die. As a renowned Continious Casting Dies Supplier, we are supplying the products through faster delivery. Moreover, you can easily find the better price with us. Our customers can easily read the information about the products online! Placing order for the product is quite easy and comfortable with us! Contact us now!

cast iron castings

Get Price Quote

10 Piece (MOQ)

Zinc Die Cast Starter Parts

20 Per Piece

5000 Piece(s) (MOQ)

aluminum die castings

Get Price Quote

Our company is looked upon as one of the prime Housing Cover Manufacturers in India. The Aluminum Die Casting, offered by us, is ideally designed to meet the specifications of different Machinery Parts. Additionally, customers are eased with the availability of the Automotive Housing Cover in varied dimensions meeting the international quality standards. Details : - - -

hss round die

Get Price Quote

100 Piece (MOQ)

Plunger Tip

1 Per Piece

50 Piece(s) (MOQ)

Aluminum Pressure Die Castings

Get Price Quote

Die Casting Parts

500 - 1,000 Per Piece

1000 Piece (MOQ)

Brass Electrical Components

Get Price Quote

Pressure Vessels

Get Price Quote

Aluminium Die Casting

Get Price Quote

We are a renowned Aluminium Die Casting Service Provider based in Delhi. Aluminium Die Casting is a green and sustainable method for rapid production of parts efficiently and precisely. We are capable to serve almost any industry and application owing to our skilled, dedicated and passionate manpower. Our professionals utilize optimum quality Aluminum die casting tools to ensure maximum client satisfaction. We produce the best quality castings that are reckoned for their lightweight, high strength, corrosion resistant properties, non-staining feature, high conductivity and many other attributes. Also, the castings are made available in different dimensions and finishes strictly as per the specifications laid by the clients

NC Servo Roll Feeder for Progressive Die

550,000 Per Piece

1 Piece (MOQ)

Blanking Dies

1,500 Per Kilogram

Sand Casting Patterns

Get Price Quote

We are the major Supplier of the finest range of Sand Casting Patterns. These Sand Casting Patterns are obtained from the prominent vendors and are manufactured from quality wooden and aluminum material. The Sand Casting Patterns that we offer are in complete accordance to the international standards. Sizes As per the client Raw Materials Aluminum and Wooden Technical Specification As per the client Applications Heavy casting foundry Packaging Wooden boxes

cast iron castings

Get Price Quote

The company is one of the credible destinations dealing in Cast Iron Castings. We hold expertise in manufacturing Cast Iron Casting up to single piece weight of 1 ton. We follow the best standards and quality specifications while designing, polishing or treating our Cast Iron Casting. Besides, the in-house inspection of our Cast Iron Castings has helped us evaluating our own capabilities.

Casting Component

25 - 500 Per Piece

2500 piece (MOQ)

We are manufacturer of Ferrous casting parts. We are supplying machined as well as raw castings. We are also supply CI Pullyes, CI Gears etc.

Magnesium Alloy Sand Casting

100,000 Per Piece

10 Piece (MOQ)

Casting Ladies Gold Rings

Get Price Quote

Manish Jewellery is the best gold casting ring supplier in Tamil Nadu. Our company has consolidated immaculate craftsmanship with cutting-edge innovation to create top-notch results for clients all through the world. Offering complete jewellery casting and manufacturing services and our expertise spans the entire spectrum of precious metal casting, including moulding and cutting, coupled with the latest 3D printing technologies and experienced CAD designers to offer a complete casting service We handle unique pieces for tailor-made gems producers or huge runs for corporate clients. We can oversee both straightforward and more mind-boggling projects and can oblige any size gems ranges and consistently plan to follow through on time. Contact us and get our services. We are the best gold casting ringsuppliers.

Investment Casting Die

Get Price Quote

1 Piece (MOQ)

Pressure Sensors

Get Price Quote

Proffering the best quality of Gauge Pressure Sensors, we are one of the highly respected Wholesale Pressure Sensors Suppliers. Our Fiber Optic Pressure Sensors are well accepted in various countries like Canada, US etc. Pressure sensors (also disposable) for all pressure ranges, in various configurations and materials of constructions for numerous applications viz:- All types of medical equipment Process plants Automation Robotics Automobiles Nuclear Defense Space

Pressure Vessels

Get Price Quote

1 Piece (MOQ)

Zinc Die Casting

Get Price Quote

50 Ton (MOQ)

Jewellery Thappa Die

1,200 Per Piece

10 Piece (MOQ)

Forging Dies

Get Price Quote

1 Piece (MOQ)

We are renowned Manufacturer & Supplier of Forging Dies which are widely demanded in the industry. Our products are capable of meeting the difficult requirements of the industries. These are designed for efficient performance and have the most robust built. We bring forth the most qualitative Forging Dies in a very reasonable price range. These are delivered to the clients well within time. Features Strong Durable Superior quality High performance

Steel and CI Casting Components

300 - 6,000 Per PIECE

2000 Piece (MOQ)

We also undertake to supply Steel and CI Casting and Machined Parts as per drawings and specifications or samples ranging from 20gms to 5000 gms with high accuracy.

Investment Casting Dies

Get Price Quote

Our packaging materials can retain the products' quality and newness even under extreme shipping and handling conditions. Our packaging provides optimum physical protection. One can approach us anytime for placing orders and expect safe and timely deliveries of the same.

rubber moulding die

Get Price Quote

1 Piece (MOQ)

Rubber Moulding Die is a Primery Tool Required for Every Rubber Moulding Machine. the Rubber Die Mould is Required During Compresion Rubber Moulding and also in Injection Moulding Process the Rubber Moulding Die is Designed to Get Desired Finish Rubber Product By Heating and Raw Rubber Under Comressed Heating Process.