Centralised Die Coating System

400,000 - 500,000 Per unit

1 piece (MOQ)

We are a well-known Centralised Die Coating System Manufacturer, Exporter and Supplier based in Maharashtra (India). Centralised Die Coating System facilitates auto mixing of die-cost in desired proportion with water. Our Centralised Die Coating System is available in diaphragm pump type and pressurized motor type models to meet all the requirements of our valuable customers. These Centralised Die Coating Systems ensure correct ratio of mixing material in entire production process. Also, Centralised Die Coating System is efficient in sustaining the die coat and water consumption in mixing process. Features : Die coat to waters proprotion.1-100 to1-1000 possible Fully automatic operation. No manual interruption One pump in spare Anti-corrosive tank and frame Centralized system to provide die coat to 7 to 8 machines from one station No Government pressure testing required Totally maintenance free unit Advantages : Compact design More accessible pressure in Auto spray or manual spray Facilitates man power elimination for die coat mixing work Uninterrupted production in all PDC machines Requires low maintenance and is easy to handle

Quick Die Change System

Get Price Quote

Emco Pressmaster Pvt. Ltd. is one of the acclaimed Manufacturers, Exporters, and Suppliers of Quick Die Change System. Our Quick Die Change System is a superb feature to get the tool / die clamped within a single digit item, enabling the valued customer to achieve competitive edge.

Best Deals from Die Change System

Die Change System

Get Price Quote

5 Piece (MOQ)

Quick Die Change System

250,000 Per Set

Die Change System

Get Price Quote

Loading a tool directly on a press bed is very dangerous using a lift cart and simply impossible to do with a crane. The bolster extension makes it possible to safely load a tool either with a lift cart or a crane. Light and sturdy : the extruded aluminium profiles is a perfect balance between strength and lightness. Gripping it manually is easy for the worker. Its sturdy conception allows it to support heavy loads.

Quick Die Change System

Get Price Quote

Emco Pressmaster Pvt. Ltd. is one of the acclaimed Manufacturers, Exporters, and Suppliers of Quick Die Change System. Our Quick Die Change System is a superb feature to get the tool die clamped within a single digit item, enabling the valued customer to achieve competitive edge.

Quick Die Change System

Get Price Quote

Quick Die Changing Systems

130,000 Per Piece

Die Change System

Get Price Quote

Air Quick Die Change System

500,000 Per Set

Quick Die Change System

800,000 Per unit

Quick Die Change System

250,000 Per Piece

QUICK DIE CHANGE SYSTEMS

300,000 Per Set

1 Set (MOQ)

Quick Die Change System

110,000 Per Piece

Quick Die Change System

Get Price Quote

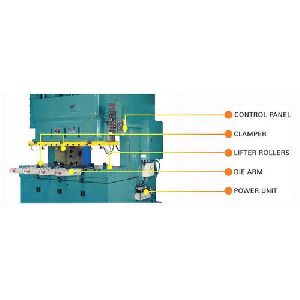

We bring forth a wide range of quick die change system for press machine that is available in multiple patterns and small quantity. Quick die change system, offered by us, saves time for the die change and also ensures the safety of the operation. We source our quick die change systems from certified vendors and thoroughly check the range before the procurement. Our quick die change system has garnered immense appreciation in the market due to the optimum performance, negligible maintenance and durability. the unit consists of : air driven hydraulic pump unit die clamp die lifter die arm operation panel

QUICK DIE CHANGE SYSTEMS

Get Price Quote

We are offering quick die change systems. Press die sets are massive precision components that must move quickly and accurately from presses to storage areas and back again. The system that performs these functions is called a qdc system, or quick die change system. There are many qdc systems used, but the rolling bolster and die cart systems are the most common. Rolling bolster systems: there are three popular rolling bolster systems: i. Single bolster operation: the bolster moves laterally in a straight line into and out of the press. This may be done at either the front, rear, or sides of the press. In this type of system the die is placed onto the bolster in a preset position and manually clamped to the bolster. The bolster is then run into the press bed area and automatically clamped into position. advantages: this system provides a means to easily install a die at a preset position, assure uniform clamping, and also insure uniform positioning in the press.

Quick Die Change System

Get Price Quote

Quick Die Change System, material handling robot

QUICK DIE CHANGE SYSTEMS

Get Price Quote

QUICK DIE CHANGE SYSTEMS, Hydraulic Shock Absorbers, Ring Blower

Quick Die Change System

Get Price Quote

Quick Die Change System, Material Handling Equipment, die loaders

Quick Die Change System

Get Price Quote

Quick Die Change System, Vibration Damping Mounts, Overload Protector