Double Cone Vacuum Dryer

Get Price Quote

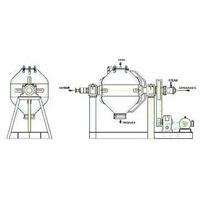

In Double Cone Vacuum Dryer, heat is supplied to double conical shaped rotating jacket. The material to be dried is kept in continuous tumbling within the rotating housing. Conical shape facilitates easy drain out of material at the end of the batch. Features Configurations Heating Media: Steam, Hot Water/Oil, Thermic Fluid. Side Mounted Choppers. Solvent Recovery.

Double Cone Vacuum Dryer

Get Price Quote

1 Piece (MOQ)

Best Deals from Double Cone Vacuum Dryer

Rotary Double Cone Vacuum Dryer

Get Price Quote

amt engineering works is a leading and well known manufacturer of rotary double cone vacuum dryer and complete pharmaceutical plants and pharmaceutical plant machinery manufacturer in india..

Double Cone Dryer

Get Price Quote

The double cone vacuum dryers is a drying equipment where jacketed vessles tumble, rotate thus mixing, drying and displacement of powderwet cake takes place. Both Vacuum and heating gives you drying of wet cake to a lower level. Easy to operate and maintain, compared to Conical DRYER.

Double Cone Dryer

Get Price Quote

Double Cone Dryer

Get Price Quote

We procure the basic material, required for manufacturing flawless lot of products, from the genuine and authorized vendors only. As a result of which, our offerings have no match in the market. Contact us our customized packaging solutions. Apart from the standard packaging options, we can pack products in wanted amount and stack them accordingly in premium packaging.

Double Cone Vacuum Dryer

Get Price Quote

We offer highly efficient Double Cone Vacuum Dryer that is constructed using high-grade materials and used for drying of heat sensitive materials that are used in the chemical and pharmaceutical industry. Our Double Cone Vacuum Dryer consists of a conical cylinder along with a jacket for the purpose of steam or oil heating. The indirect heating process is carried out under vacuum and recovery of solvent becomes possible by condensing the vapor generated during the operation. The Double Cone Vacuum Dryer rotates at a slow RPM in order to ensure gentle agitation of the entire mass.

Double Cone Vacuum Dryer

Get Price Quote

We offer our clients a wide range of Rotary Cone Vacuum Dryers that is available in various capacities ranging from 20 Ltrs. to 5000 Ltrs. Our range is manufactured using superior quality material, and is available in STD, GMP & CGMP designs. Further, these can also be customized as per the specifications provided by our clients.RCVD is suitable for drying & mixing powder (raw materials), pharmaceutical materials, crystalline products, insecticides, pesticides, food products & also for heat sensitive products. The equipment can also be used as rotary evaporator.

Double Cone Dryer, Blender

Get Price Quote

We are offering double cone dryer, blender etc.this type of dryer is, to some extent, replacing the agitated rotary vacuum dryer. It has two opposing jacketed cones on a common jacketed short cylindrical base. When the cones are in a vertical position the dryer can be rapidly discharged. The unit is provided with supporting trunnions running on suitable bearings. The trunnions are hallowing. A vacuum connection is made through one of the trunnions. The connection pipe is turned upwards in the cone and is fitted with a dust filter as its end. Inlet and outlet pipes pass through the outer trunnion for the supply of suitable heating medium to the jacket. A special design of a rotating valve is used for this purpose. One of the trunnions is driven through a reduction gear and chain drive. rotation speed will range from 12 rpm for small units to 3 to 4 rpm for large commercial installations. the horse powers vary between 0.5 and 15 the base cylinder diameter is about 1m to 3m.

Rotary Double Cone Vacuum Dryer

Get Price Quote

Rotary Double Cone Vacuum Dryer Rotating Cone With Vacuum Dryer is high precision low temperature vacuum drying. The Rotated Double Cone Vacuum Dryer’s suitable for drying the material which operates at low temperature, easily oxidized, poisonous in nature. It has high efficiency heat transfer and high speed drying which save energy. Raw materials are dried uniformly and have good quality at low temperature Special Features of Rotary Vacuum Dryer Reduces drying time Total contained process, dust control Efficient Loading and Discharge Choppers / Battles (Lump breaker) give lump free product Easy Openable Charging pot Eliminates need for re-crying of lumps Handing and exposure offal products avoided Easy to clean internal surface, thus ensuring purity of product Dimensions and capacities are approximate and subject to change. Do not use for installation, consult us : Operating capacity s 65% of total volume Standard jacket s Horsepower Is based on bulk density of 50 lbs/ft3 and natural angle response of 45D Rotational speed can be changed based on product characteristics. Standard Drive : A = gear & pinion B = chain & sprockets C = hollow – bore (optional on most models)

Double Cone Vacuum Dryer

Get Price Quote

SS316 rotocone vacuum dryer - double cone vacuum dryer, ss jacketed, without gear box & electric motor, size cone slanting 43 inches, sides 40 inches, diameter 87 inches

SZG Double Cone Rotating Vacuum Dryer

Get Price Quote

We are staffed with the most up to date machines and cutting-edge technology for the testing of raw material and thus, with without fail we carry out stern quality examinations of the same at the initial stages. We have hired a team of professional quality experts to carry out diverse quality tests in order to ensure zero defects at buyer's end.

Double Cone Rotary Vacuum Dryers

Get Price Quote

Batch operations mainly for crystalline free flowing powders Quick opening charging and discharge valves Effective Dust collector system Mechanical Seal for high vacuum applications Easy to clean and maintain

Double Cone Dryer

Get Price Quote

The Rota Double Cone Vacuum Dryer is suitable for drying the material which can not operate at low Temperature easily oxidized, poisonous in nature. The Double Cone Rotating Vacuum Drying Equipment is a new drier that integrates mixing and drying in the one body and equips with condenser and vacuum pump. Therefore the vacuum drier is formed. The drier is advanced in design, simple in inner structure, easy for cleaning, to discharge all raw material, convenient in operation and improving work environment. Meanwhile raw material is rotating accompanying with the rotating of container; raw materials cannot be accumulated onto the wall of container, so it has high efficiency heat transfer and high speed drying which save energy. Raw materials are dried uniformly and have good quality at low temperature. It can widely apply to dry raw materials of pharmaceuticals, chemical, Pesticides, foodstuff , dyestuff and so on industries. The equipment is in conformity with the requirements of "GMP". If the solvent does not recover, the condenser may be not used. Option for advance PLC Controls with HMI touch screen , Option for Flame Proof Electrical. Option for condenser, Receiver & Cyclone for solvent recovery, Option for heating media steam hot water hot oil.

Rotary Double Cone Vocuum Dryer

Get Price Quote

Capacity: 5 Litres to 5000 Litres Application: Rotary double cone vacuum dryers are suitable for drying & mixing powder (raw materials), pharmaceutical materials, crystalline products, insecticides, pesticides, food products & also for heat sensitive products. The equipment can also be used as rotary evaporator. Promas Engineers is a certified company for manufacturer, supplier and exporter of rotary double cone vacuum dryers according to ISI guidelines and user’s requirements since 1990 from Mumbai to India and all over the world. Working Principle Rotary Double Cone Vacuum Dryers Raw material is charged in batches & is subjected to indirect heating while at the same time undergoing rotary motion of the cone assembly. The conical shape of the dryer ensures efficient circulation of hot liquid heating media. Drying takes place when heat flows from outer cone through a jacket, and vacuum is applied in the inner cone. The drying operation is based on the principle that water or other volatile product moves from a zone of low pressure. This is accomplished by warming the product to be dried to raise the vapour pressure of the absorbed or free liquid by vacuum or by sweeping it with Air or Nitrogen current. Thus the essential conditions for effective drying are achieved by uniform heat transfer throughout the batch and rapid removal of the vapour. The vacuum is applied gradually with PLC control by throttling. Promas Engineers Rotary Double Cone Vacuum Dryer is unique in removing complete water, or other solvent from wet powders coming from a filtration unit or a centrifuge. It can be used as an effective dryer, fast mixer & blender or homogenizer. It can also be used as a granulator. The drying time is substantially reduced because of high-speed choppers, which help the evaporation of the solvent or moistures. Chopper speed can be controlled by a frequency drive. Dryer are manufactured as per “US-FDA” Standards & Regulations. Salient Features Rotary Double Cone Vacuum Dryers Low temperature drying under vacuum Higher Thermal Efficiency Specially designed micro air-filter can be provided on receiver while breaking vacuum for safety operation Nitrogen purging system is available optionally for mechanical seal as well as for cleaning filter Specially designed S.S. Rotary union is provided for hot water or steam at inlet & outlet Direct drive with hollow shaft gear to suit cGMP operation & to avoid greasing of the gear. The gear box with only one time of oil fill for lifetime Lowest energy consumption compared to any other batch type dryer due to higher differential temperatures Available in STD/GMP/cGMP/ Lab Models and kilo lab models Why RCVD? Suitable for drying of materials which cannot resist high temperature. Material which are easily oxidized Specialty chemicals Volatile Materials which should be retrieved Materials which are strong irritants and poisonous in nature Solvents which need to be recoverer Advantages: Reduces drying time. Total contained process, dust control. Efficient Charging and Discharge. Choppers (Lump Breaker) give lump free product. Easy Open-able charging port. Eliminates need for re-drying of lumps. Handling and exposure of final product is avoided. Gives uniformity size dry product. System can process crystalline or amorphous powders which are prone for lumps. Easy to clean internal surface, thus ensuring purity of product. Optimum and Continuous vacuum maintenance during process. Uniform material shuffling over the heated contact surface of the cone.

Rotary Double Cone Vocuum Dryer

Get Price Quote

Application: Rotary double cone vacuum dryers are suitable for drying & mixing powder (raw materials), pharmaceutical materials, crystalline products, insecticides, pesticides, food products & also for heat sensitive products. The equipment can also be used as rotary evaporator. Promas Engineers is a certified company for manufacturer, supplier and exporter of rotary double cone vacuum dryers according to ISI guidelines and user’s requirements since 1990 from Mumbai to India and all over the world. Working Principle Rotary Double Cone Vacuum Dryers Raw material is charged in batches & is subjected to indirect heating while at the same time undergoing rotary motion of the cone assembly. The conical shape of the dryer ensures efficient circulation of hot liquid heating media. Drying takes place when heat flows from outer cone through a jacket, and vacuum is applied in the inner cone. The drying operation is based on the principle that water or other volatile product moves from a zone of low pressure. This is accomplished by warming the product to be dried to raise the vapour pressure of the absorbed or free liquid by vacuum or by sweeping it with Air or Nitrogen current. Thus the essential conditions for effective drying are achieved by uniform heat transfer throughout the batch and rapid removal of the vapour. The vacuum is applied gradually with PLC control by throttling. Our Specialities Creating innovative and cost effective designs as per your requirement to give you maximum and best output from our equipment Providing Lab Models in exactly the same material to give the accurate results Design and supply of entire turnkey projects at any scale, from 500 kgs to 20,000 kgs capacities. Promas Engineers Rotary Double Cone Vacuum Dryer is unique in removing complete water, or other solvent from wet powders coming from a filtration unit or a centrifuge. It can be used as an effective dryer, fast mixer & blender or homogenizer. It can also be used as a granulator. The drying time is substantially reduced because of high-speed choppers, which help the evaporation of the solvent or moistures. Chopper speed can be controlled by a frequency drive. Dryer are manufactured as per “US-FDA” Standards & Regulations. Salient Features Rotary Double Cone Vacuum Dryers Low temperature drying under vacuum Higher Thermal Efficiency Specially designed micro air-filter can be provided on receiver while breaking vacuum for safety operation Nitrogen purging system is available optionally for mechanical seal as well as for cleaning filter Specially designed S.S. Rotary union is provided for hot water or steam at inlet & outlet Direct drive with hollow shaft gear to suit cGMP operation & to avoid greasing of the gear. The gear box with only one time of oil fill for lifetime Lowest energy consumption compared to any other batch type dryer due to higher differential temperatures Available in STD/GMP/cGMP/ Lab Models and kilo lab models Why RCVD? Suitable for drying of materials which cannot resist high temperature. Material which are easily oxidized Specialty chemicals Volatile Materials which should be retrieved Materials which are strong irritants and poisonous in nature Solvents which need to be recoverer Advantages: Reduces drying time. Total contained process, dust control. Efficient Charging and Discharge. Choppers (Lump Breaker) give lump free product. Easy Open-able charging port. Eliminates need for re-drying of lumps. Handling and exposure of final product is avoided. Gives uniformity size dry product. System can process crystalline or amorphous powders which are prone for lumps. Easy to clean internal surface, thus ensuring purity of product. Optimum and Continuous vacuum maintenance during process. Uniform material shuffling over the heated contact surface of the cone.

double cone rotary vaccum dryer

Get Price Quote

Most suitable for drying of materials which can not resist high temperature, material which are easily oxidised, volatile materials which should be retrieved, materials strong irritant and poisonous in nature. The rotocone dryer with improved technology integrates during operation under vacuum. The rotocone dryer facilitates enhanced drying efficiency, low temperature operation and economy of process by total solvent recovery.Advantages :Reduces drying time Uniform material shuffling over the heated contact surface of the cone. Handling and exposure of final product is avoided. Eliminates need for redrying of lumps. System can process crystalline or amorphous powders which are prone for lumps Optimum and continuous vacuum during process.Salient Features :Totally sealed & protected from contamination.Provision of sampling nozzle without breaking vacuum.Cyclone separator provided for recovery of any solid particle escape.Suitable size condenser & receiver provided for solvent.Mechanical seals for vacuum & hot water connection.Variable speed drive is provided for fine adjustment of the speed.

Double Cone Dryer

Get Price Quote

We are one of the leading Manufacturers and Suppliers of superior quality Double Cone Dryer. It is highly demanded double cone dryer for drying & mixing pharmaceutical materials like powder & granule.

Double Cone Vacuum Dryer

350,000 Per unit

Double Cone Dryer

Get Price Quote

Double Cone Blender is an efficient and versatile machine for mixing of dry powders and granules homogeneously. All the contact parts are made of stainless steel. The effective volume for optimum homogeneity is between 35-70% of gross volume. The SLANT double cone design eliminates dead spots which occasionally occur in conventional double cone mixer. It can be used for pharmaceutical, food, chemical, cosmetic products etc.