Double Ended Flanging Machine for 200ltrs Barrel

Get Price Quote

Edge grinding is very special operation in manufacturing of drums & barrels, because some amount of material is to be removed from the edges of the body which give advantages to a) welding operations 9removes dirt, oiliness etc), extra strength to the weld and a leak proof joint. B) flanging operation. C) end seaming operation (lesser thickness of side seam overlap). Maximum parts of the machine ate steel fabricated. It can absorb all the jerks & vibration caused due to the grinding wheel. Proper dressing arrangement is for smooth grinding. The entire machine is divided in 3 parts as a) centre table on fixed guide rails by means of pneumatically operated long cylinder. B) right hand side grinding unit. C) left hand side grinding unit. All the tree units are properly assembled; micro setting arrangement is given for maintaining highly precise gap between the grinding wheels.

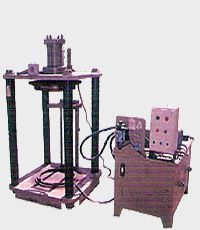

Double Ended Flanging Machine

Get Price Quote

We are offering double ended flanging machine manufacturers, exporters, and suppliers located in india our double ended flanging machine is equipped with two flanging tools and is fabricated using high quality steel. Our double ended flanging machine gives an appropriate end seam to the drums and barrels. features : robusttensile strength excellent performance maximum durability anti- corrosive highly reliable used for : giving flange to the drum or barrel.

Best Deals from Double Ended Flanging Machine

Double Ended Flanging Machine

Get Price Quote

The machine is required for giving flange to the drum or the barrel. For getting good seam, proper even flange is essential. This machine contains two flanging tools made out of good quality steel, which are heat treated and ground is also has a separate hydraulic power pack of all standards parts, high quality flexible tubing, logic, and control panel, high quality hydraulic cylinder etc. the main advantages in this is that rejection rate is almost nil and gives both the flange simultaneously, it also gives very fast trouble free production, and unskilled operator also can operate this machine. Operation is very safe because drum does not rotate. We get even flange and very precise diameter of drum and barrel body, no bucking, no unevenness of flange no wrinkle to flange (usually all this defects are experienced in rotary flanging machine.)

Double Ended Flanging Machine

Get Price Quote

This machine has been developed for flanging both ands of round cans body specially for the larger type of decorative can where the decoration is of the great consideration. The machine is quickly adjustable for varying sizes; the left hand flanging head is fixed, the right-hand head moves along the length of the bed.