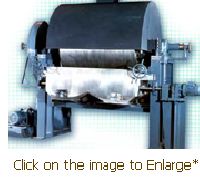

GMP Drum Flaker

Get Price Quote

100 Piece (MOQ)

Other details: • Flaker used to convert molten chemical in to solid flakes • This is achieved by forming a thin layer of molten product on the outside surface of a rotating drum and causing this to be solidified by spraying cooling water from inside surface of the drum • An adjustable scrapper continuously removes the solidified from the drum surface in flake forms • The material of construction for the drum can be mild steel, stainless steel with hard chrome plating, normally mono-block for weldable materials • This construction ensure lifelong alignment, surface will be machined and ground finished • Drum rotating on anti-friction self aligning ball / roller bearing with standard housing • Heavy duty drive arrangement for smooth, continuous and trouble free running • V-Pulley or Variable speed arrangement also provided for optimum performance • The Flaker Machine will be complete with 1440 RPM, 3 Phase, 415 volts, TEFC / ISD motor, with gear box, Tray, Hopper, M.S. hood, Belt Guard • Machine mounted on heavy base-plate for trouble free service • It's optional features is Screw Conveyor, Flaker Breaker, Film thickens controllers, Complete enclosure for Hazardous application

Drum Flaker

Get Price Quote

Special applications include single drum, double drum, twin drum and custom flaker.

Best Deals from Drum Flaker

Rotary Drum Flaker

Get Price Quote

Flakers are used for solidifying molten material. After processing on flakers, the material forms films or easily handled flakes and is further processed or packed into containers for transport. A great advantage of flakers is that they offer a continuous process. The hot material is applied to the cooling drum by direct immersion into a trough, or indirect immersion using doctor/applicator rolls. The molten liquid is cooled on the cooling drum and after a partial revolution; the cooled and solidified product is removed by a scraper in the form of flakes or film.We manufacture, design and develop optimum quality rotary drum flakers. Our range of drum flakers is available in single drum flakers, double drum flakers.Material of Construction (MOC) Offered :- CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), SS 316, SS 304, SS 316 L, SS 304 L. SS 310, MONEL, INCONEL, TITANIUM, HASTALLOY, PP/FRP ETC.Special Features : Designed for trouble free operation Low Cost operation Continuous Process High thermal efficiency Minimum thermal degradation Accomplishment of flaking in a single step Uniformly flaked product

Drum Flaker

Get Price Quote

We have been able to manufacture and supply a wide range of cooling drum flakers. Drum flaker offered by us are widely demanded by the clients for multiple usage. We manufacture drum flaker using high-grade raw material and advanced technology. with firm commitment to quality, we are engaged in manufacturing and supplying drum flakers. Extensively used for solidifying molten material, these drum flaker are manufactured under the guidance of experienced professionals, who strictly follow the established norms and standards of the industry. In addition to this, our professionals ensure to use modern machines and high grade material to manufacture these drum flaker .

Drum Flaker

Get Price Quote

Rarely Used Flaker - Drum Dryer Machine In Ready to start condition, Open Type Hard Chrome Plated Double Drum, Drum MOC: Drum cylinder is MS with Hard Chrome plated rolled and welded. The End plate MS. The Turnions hollow in MS construction with Hard Chrome Plated.Suitable drive consisting of 5 HP, TEFC motor, having 1440 RPM, and reduction gear box with V-pulley arrangement

Drum Flaker

100,000 Per Piece

1 Piece (MOQ)

Drum Flakers

500,000 - 5,000,000 Per Piece

1 Piece(s) (MOQ)

We make drum flakers for all industries . Production rate 50 kgs to 5000 kgs per hr

Rotary Drum Flaker

Get Price Quote

We offer the rotary drum flaker as below, rotary drum flaker salient features :- • continuous type dryers and coolers • suitable for solid separations from liquids without filtration operation • bigger solid particles flakers • suitable for sticky materials, resins, snacks, food fine chemicals • direct air heated, hot water, steam or electric heater for more details please contact us.

Drum Flaker

Get Price Quote

The Rotary Drum Flaker consists of a cylindrical drum, having provision for cooling drum surface. One end of the drum shaft is connected to a gear box which is driven by a motor. The heating cooling media will be circulated in drum during operations, the drum rotates at a slow speed. A thin layer of the product to be dried cooled, adheres to the outside of the rotating, drum and internally cooled drum. The product gets solidified and is after an almost complete rotation, scrapped off drum surface and at the same instant granulated in the form of flakes, falls on screw conveyor. At the bottom of conveyor, filling point is provided to fill the bag. The entire process is continuous operation, does not require manpower except bag filling. Pneumatic hydraulic operation of scraper assemblies can be provided.

Drum Flaker

Get Price Quote

In Drum Dryer chamber, the material driescools on its surface of an internally heatedcooled revolving drum. The product to be driedcooled revolving drum. The product to be driedcooled is usually in fluidslurrypaste like form with the solids in either solution or suspension. q

Drum Flaker

1,500,000 Per unit

Drum Flaker

Get Price Quote

Drum flakers (also known as cooling drums) are used for solidifying molten material. After processing on flakers, the material forms films or easily handled flakes and is further processed or packed into containers for transport. A great advantage of flakers is that they offer a continuous process.

Drum Flaker

Get Price Quote

Used for converting molten slurriers into dried solid flakes. In the Drum DryerFlaker material is fed into a feed hopper which directs the materials on to the face of a rotating drum. The drum is heated or cooled depending on the application to enable the material to cling to the outside of the drum. The material is dried during the rotation of the drum and is removed by a blade or scrapper mounted along the length of the roll. Materials processed in the drum dryer are caustic soda, resins, waxes, fatty acids, guar gum, sulphur dyes etc.

Drum Flaker

Get Price Quote

Welcome to Suresh Engineering Works the most cost effective & reliable manufacturer of Chemical Processing Machineries We take pleasure to introduce ourselves as manufacturers of Various Machinery required by Chemical, Pharmaceutical, Bulk Drugs, Dyes, Pigments, Food, Paints, Plastics, Soaps & Detergents, Adhesives & Coatings, Ceramic Industry.

Drum Flaker

Get Price Quote

Backed by the years of experience in this domain, we are passionately engaged in offering optimum quality Drum Flaker. It does not require the use of manpower; our offered drum flaker is designed by our professionals by using finest components as per the set guidelines. In addition to this, we offer this drum flaker in various specifications and can be further customized on demand. Offered drum flaker is demanded in the market for its performance.Features: Easy to maintain High functionality Precisely engineered

Drum Flaker

535,000 Per Piece

Drum Dryer Flaker

Get Price Quote

In this conductive dryer, wet feed film (in liquid or paste form) is poured on the rotating metal cylinder. Heating medium flows inside the cylinder. Feed dries into a film and is scraped off. This dryer is suitable for continuous drying. We are best Drum Dryer Flaker Manufacturers. Special Features of Drum Dryer Flaker : Feed can be liquid or pasty Product in powdery, flaky form Uniform drying High thermal efficiency Continuous operation Drying in single step, eliminating need for intermediateconcentration processes Application : Winnies Foods, paraffin wax, clay, fire clay, plaster slag, pasty green waste ,sewage sludge, agricultural products , grain, root vegetables, etc.

Drum Flakers

Get Price Quote

we offer drum flakers. we are well known manufacturing and supplying company of drum flakers. special features: low power demand - continuous operation - compact installation - closed construction available

Drum Flakers

Get Price Quote

Drum Flakers Dryer is also known as Flakers dryer. For the drying of material the Drum Flakers dryer is used widely, and usually it is single drum dryer and Double drum dryer. The drum flaker is used primarily to process chemical and pharmaceutical products. However, more and more applications for these machines are also being found in the food industry. The required flake size is achieved by controlling circumferential speed, layer thickness, and knife angle. Careful design ensures optimum use of the drum surface area to maximize capacity at the chosen operating conditions. The drum flaker is primarily used to produce Flakers, but there are also ways of converting your product into easily manageable pastilles or prills. Applications: Techno Enterprise’s Drum Flakers dryer is specially developed for vast range of applications: Textiles Industries Pharmaceuticals Industries Food products Chemicals Industries Paper Industries Pigments Starch Products Pesticides and fertilizers Adhesives Industries Many Other Drying Applications.

Drum Flaker

Get Price Quote

Drum flakers (also known as cooling drums) are used for solidifying molten material. After processing on flakers, the material forms films or easily handled flakes and is further processed or packed into containers for transport. A great advantage of flakers is that they offer a continuous process. Salient Features : Variable speed drive arrangement for adjustment of the drum speed for optimum performance, Suitable for a wide range of chemical and pharmaceutical products, Contact parts can be stainless steel, carbon steel, and hard chrome plated depending on material requirements, Accessories include hood, flake breaker, flake conveyor, applicator roller etc.