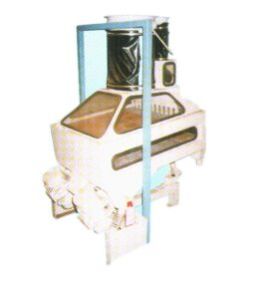

dry destoner

Get Price Quote

We are reckoned as a credible name for offering highly efficient destoner machine. This destoner machine finds its application in the seed handling industries, wherein same size stones have to be removed from seeds before processing.

dry destoner

175,000 - 198,000 Per Piece

1 Piece (MOQ)

Best Deals from Dry Destoner

dry destoner

Get Price Quote

It can be used in soybean oil seed processing plant, maize starch factories, roller flour mills, rice mills, and other food industries.

dry destoner

Get Price Quote

Dry destoner . Make payment securely with a payment option you are comfortable with. We accept payment through offline as well as online modes. We make sure proper documentation is done.

dry destoner

Get Price Quote

The Satake Destoner SGA separates stones and heavey impurities from grains, utilizing bulk density differences. Rigid, heavy-duty construction with thicker lifesteel plates and a strudy frame ensures long life. This is the ideal machine for separating stones from grain in an efficient, trouble free manner.Stone Discharging and Resort Mechanism:The discharged stones from the primary sieves contain some grains. This mixed fraction is sent to the secondary sieve by a pneumatic transfer system, using a built-in fan. Stones are concentrated and discharged.Very Low Maintenance:Heavy-duty construction, (side View) permanent lubrication and easy access to sieves for cleaning or Replacement result in very low maintenance.Compact Design:The Satake Destoner is a compact unit and requires less installation space. The vibratory drive eliminates the need for any pulleys, belts, eccentric bearings, etc. and contributes to the improved sanitation in plants.

dry stoner

Get Price Quote

The Mukul Dry Stoner is used in the flour, Semolina and grain cleaning plants. It is an inevitable machine for the cleaning uints of dry system. The Mukul Dry Stoner machine accurately separate the stone of granular products such as wheat, barley, maize, rice, lentil, chickpea, bean and sesame. The product to be separated from the stone is transferred without interruption on the sieve. Grain is caused to float on the sieve by the means absorbed air top part. The heavy particles stay on the sieve. These heavy perticles are sent to higher plateform by the means of circular movement of the sieve. The stone is discharged from the one front outlet and cleaned product is discharged from the double outlet in the backside of machine. Air has the most important role for the cleaning of the product from the foreign materials. The aspiration is choosen according to the capacity of machine and the air is adjusted according to sort of product in the air valves.

dry stoner

Get Price Quote

Dry Stoner is a machine used to remove stones, mud balls, glass or metal pieces, leguminous seeds, shelled seeds and other high-density matter from the grain stream. APPLICATIONS OF DRY STONER Flour and semolina mills Cereal Cleaning Plants Corn Factories Oil Factories Cocoa and Coffee Plants Breweries and distilleries In the production of ethanol WORKING PRINCIPLE OF DRY STONER In the Dry Stoner, the product flows through the feeding chamber onto a vibrating separating deck and is acted upon by vibration and air flow which separates the stone from the cereals. The dedicated research team of Mukul Enterprises have concluded that the most critical anomally in a Dry Stoner is the Air Flow and have successfully mastered the technology. Thus, the main purpose of Dry Stoner is achieved easily due to oscillation difference resulting in the proper separation of heavy particles and product easily. Even small, lighter stones roughly the size of a grain kernel are also removed from the grain stream.Best operation can be achieved keeping several factors in mind, such as : Frequency and amplitude of vibrations. Suspension effect of the cereals caused by the airflow. Inclination of the processing deck. FEATURES & ADVANTAGES OF DRY STONER Low energy consumption, high capacity and operating efficiency. Minimum and easy periodic maintenance. Durability, long lifetime, easy and quick replacement of mesh. Precise adjustment and inclination of mesh deck. Dust-free construction Easy cleaning and maintenance. Noiseless working condition

dry stoner

Get Price Quote

dry destoner

Get Price Quote

The provided destoner is manufactured with the use of best quality components as per set quality standards. Finding its application in the seed handling industries, it is used for removing stones from grains. Apart from this, our clients can buy the provided Dry Destoner at economic rates from us.

dry stoner

295,000 Per Piece

1 Piece (MOQ)

dry destoner

Get Price Quote

dry destoner, Bin Activator, vibro screen separators

dry destoner

Get Price Quote

We are offering dry destoner. Dry destoners are used for removing stones from green coffee, dry parchment and dry cherry. The destoner is designed to take advantage of the difference in specific weights between the stones and the coffee. Description machine (hp) aspiration (kw) air lock (kw) dry cherry dry parchment green coffee pvs 3 0.75 0.75 0.75 600-1000 800-1200 1800-2100 pvs 7 0.75 10.0 0.75 1600-2000 1400-2000 3200-4000 pvs 15 2x0.75 15.0 0.75 3200-4000 2800-4000 5000-6000

dry destoner

Get Price Quote

dry destoner, INTENSIVE DAMPENER, Pneumatic Accessories, Hp Fan and LP Fan

dry destoner

Get Price Quote

dry destoner, Pressure Valves, high pressure rotary valves, Pressure Vessel

dry destoner

Get Price Quote

dry destoner, Air Compressor, grain color sorter, Rice Mill, Rice Grader

dry destoner

Get Price Quote

dry destoner, Par Boiling Unit, Thickness Grader, Rice Polisher Machine

dry stoner

Get Price Quote

dry stoner, BRAN FINISHER, IMPACT DETACHER, INTENSIVE DAMPENER

dry destoner

Get Price Quote

dry destoner, Wheat Grading Machine, Vacuum Destoner, Pulse Cleaning Machine

dry stoner

Get Price Quote

dry stoner, powder feeder, INTENSIVE SCOURER, worm conveyor

dry destoner

Get Price Quote

dry destoner, New 7 Stage Lint Cleaner, Rotary Ball and Sand Cleaner