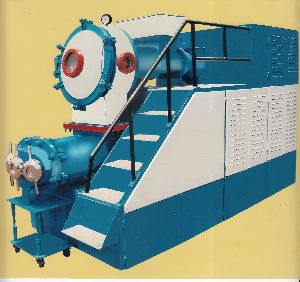

Duplex Vacuum Plodder Machine

405,000 Per Piece

Single Worm Duplex Vacuum Plodder

Get Price Quote

Single Worm Duplex Vacuum Plodder Produces Compactly Finishes Soap Bar Top Stage Known As Preplodder Extrudes the Soap As Noodles/pellets Noodle From the Preplodder Is Passed to the Vacuum Chamber Soap in the Vacuum Chamber Is Plodded Out As Compact Bar Product Contact Parts Are Made of SS 304 Top Plodder Is Driven by one Motor and Gear Box Bottom Plodder with another Motor The Barrels of the Plodder Are Jacketed for Chilled Water Circulation End Cone with Taper Mouth Is Fitted with Heating Jacket for Smooth Plodding Vacuum Chamber Is Fitted with Wing Nuts for Easy Open/close and View Glasses Heavy Duty Thrust Bearings Are Provided for the Worms to Withstand Extruding Load

Best Deals from Duplex Vacuum Plodders

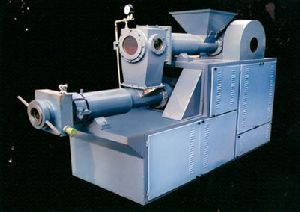

Vacuum Plodder

Get Price Quote

Vacuum Plodder has two stages, driven by independent transmission system. The length-diameter ratio of screw can be 1:9.The first plodder is acting as a simplex refining to make soap pellets in the vacuum condition. In the final plodder, the soap is pressed and extruded out billets through the orifice to feed the downstream cutter or stamper.All gears are precisely manufactured. The screws are made of high quality stainless steel or aluminum alloy, which are strong corrosion-resistant and durable for long production. All other parts in contact with the soap are made of high quality stainless steel. The production capacity can be adjusted by the VFD or the electromagnetic speed regulation motor.

Duplex Vacuum Plodders

270,000 Per Piece

1 Piece (MOQ)

Twin Worm Duplex Vacuum Plodder

1,000,000 Per Piece

1 Piece(s) (MOQ)

Duplex Plodder

500,000 Per Piece

1 Piece(s) (MOQ)

Single Worm Duplex Vacuum Plodder

Get Price Quote

Vacuum Plodder

200,000 - 1,200,000 Per Bag

This machine has two stages, driven by independent transmission system. First plodder acts as a simplex refining to make soap pellets in the vacuum condition. In second plodder, soap is pressed and extruded in fine billets through the die or cutter. Features : Convenient to install and operate Low maintenance Available in varied specifications

Twin Duplex Vacuum Plodder

Get Price Quote

With stern quality analysis of the raw materials and other inputs used, we make certain that the final product is absolutely free from defects. For this, we make use of the updated technology and machines. We do not have to worry about stock-out situations or meeting bulk requirements, as we have an equipped warehouse facility. It has the latest inventory control and management software and helps us maintain continuous product availability. Features: High-Performance Sturdy Structure Long Service Life

Vacuum Plodder

Get Price Quote

Here in this machine the soap is finally converted into shape of Bar as per the design of die fixed at the discharge mouth of Plodder. The material is extruded under provided vacuum condition within the machine. This is a two stage machine in first stage the noodles are prepared which are dropped into second stage by gravity which are finally converted into required cake size. Since our establishment in the year 1995, we are engaged in offering our clients excellent quality Vacuum Pump. This pump is manufactured by team of our experts with the aid of latest technology by utilizing excellent quality components in compliance with global industry standards. The offered pump is extensively used in industries for removing gas molecules from a sealed volume in order to leave after a partial vacuum. Our esteemed clients can avail this quality tested range of Vacuum Pump in distinct specifications at industry-leading prices. Type 1 : Prod : 500 Kg Twin : 6” Power : 5 HP/7.5 HP motor Vacuum pump : 1 HP Type 2 : Prod : 1 Ton Twin : 8” Power : 10 HP/ 15 HP motor Vacuum pump : 3 HP Type 3 : Prod : 1.5 Ton Twin : 10” Power : 15 HP/ 20 HP motor

Single Worm Duplex Vacuum Plodder

Get Price Quote

Single Worm Duplex Vacuum Plodder Produces Compactly Finishes Soap Bar Top Stage Known As Preplodder Extrudes the Soap As Noodles/pellets Noodle From the Preplodder Is Passed to the Vacuum Chamber Soap in the Vacuum Chamber Is Plodded Out As Compact Bar Product Contact Parts Are Made of SS 304 Top Plodder Is Driven by one Motor and Gear Box Bottom Plodder with another Motor The Barrels of the Plodder Are Jacketed for Chilled Water Circulation End Cone with Taper Mouth Is Fitted with Heating Jacket for Smooth Plodding Vacuum Chamber Is Fitted with Wing Nuts for Easy Open/close and View Glasses Heavy Duty Thrust Bearings Are Provided for the Worms to Withstand Extruding Load

Single Stage Duplex Vacuum System

Get Price Quote

Twin Worm Duplex Vacuum Plodder

Get Price Quote

Here in this machine the soap is finally converted into shape of Bar as per the design of die fixed at the discharge mouth of Plodder. The material is extruded under provided vacuum condition within the machine. This is a two stage machine in first stage the noodles are prepared which are dropped into second stage by gravity which are finally converted into required cake size. Mixing, Noodle Making, Extrution, Phase Conversion, Binding, Air Bubble Sucking are the Major Feature of this Machine.

Vacuum Plodder

Get Price Quote

Twin Worm Duplex Vacuum Plodder Refines the Soap Mixture to Smooth Bars Duplex Plodder Comprise of Pre Plodder and Final Plodders Driven Individually The Mixture Is Extruded by Twin Screws in Pre plodder Orifices of Noodle Plate Rotary SS Shredders on Worms Cut Equal Lengths Noodles & Pass to Vacc.Chamber Vacuum Chamber Connects the Pre Plodder and Final Plodder with Openable Lid Final Plodder Compacts the Soaps to A Fine Finished Bar by Its Conical Jacket Mouth Twin Cylindrical Barrel Made of SS 304/ MS and Precision Machined Inners Barrel Is Constructed with Thick Back Flanges to Match to the Twin Output Gearbox The Barrel Is Jacketed and Pressure Tested for Chilled Water Circulation Twin Screws Are of 300 mm Dia Each with Left and Right Flutes with Reduction Pitch Screws Are Solidly Casted SS 304, X Ray Tested with Flights for Positive Extrusion The Worm Shaft Is Supported at the End Through Heavy Duty Thrust Bearing Housing One Motor at the Top Stage and another Motor at the Bottom Stage Double extrusion mouth with Heating system

Twin Worm Duplex Vacuum Plodder

Get Price Quote

GHEC is trsuted name as a Twin Worm Duplex Vacuum Plodder manufacturers in India. Here in this machine, the soap is finally converted into shape of Bar as per the design of die fixed at the discharge mouth of Plodder. The material is extruded under provided vacuum condition within the machine. This is a two stage machine. In first stage, the noodles are prepared which are dropped into second stage by gravity which are finally converted into required cake size. Mixing, Noodle Making, Extrution, Phase Conversion, Binding, Air Bubble, Sucking are the major features of this Machine.

Duplex Vacuum Plodder

Get Price Quote

We manufacture toilet soap duplex plodder vacuum machine which is used in toilet soap making industries. The vacuum pump in the said machine ensures a moisture free, solid material to produce a solid high quality toilet soap with fine finish. Model Motor Batch Capacity KH 6 15HP 150 kg./Hour KH8 20HP 300 kg./ Hour KH10 30HP 600 kg./ Hour

Duplex Twin Worm Vacuum Plodder

Get Price Quote

Here in this machine the soap is finally converted into shape of Bar as per the design of die fixed at the discharge mouth of Plodder. The material is extruded under provided vacuum condition within the machine. This is a two stage machine in first stage the noodles are prepared which are dropped into second stage by gravity which are finally converted into required cake size. Mixing, Noodle Making, Extrusion, Phase Conversion, Binding, Air Bubble Sucking are the Major Feature of this Machine.

Duplex Vacuum Plodder

Get Price Quote

With the assistance of our experienced professionals, we are able to offer a premium grade Duplex Vacuum Plodder. Our business is based in Uttar Pradesh, India. We offer it in twin worm and single worm formation. The construction of our offered machine is either cast or solidly fabricated. Our professionals engineer it with the utmost precision by using the advanced machinery and equipment. We are competent to take bulk orders for it. It is available at the leading market rates. Details :Worms Used in Our Plodder are Made of Ss/ Ms/ En8/ Alluminium Construction Either Casted or Solidly Fabricated.

Duplex Plodder

Get Price Quote

One of the suppliers of industrial products, providing various types of products such as duplex plodder.

Duplex Vacuum Soap Plodder

Get Price Quote

Duplex Vacuum Plodder

Get Price Quote

We are offering duplex vacuum plodder. The modern toilet soap manufacturing facilities uses a duplex vacuum plodder for final refining, compacting & air free extrusion of a continuous bar. Duplex vacuum plodder consists of two plodders mounted in tandem and connected by a vacuum chamber.

Duplex Plodder

Get Price Quote

Duplex Plodder, DETERGENT POWER MIXER, Plodder, Mixer, Belt Conveyors

Duplex Vacuum Plodders

Get Price Quote

Duplex Vacuum Plodders, Soap Stamping Machines, Soap Cutting Machine

Duplex Vacuum Plodder

Get Price Quote

Duplex Vacuum Plodder, Die Soap Stamping Machine

Duplex Vacuum Plodder

Get Price Quote

Duplex Vacuum Plodder, Stainless Steel Cutting Machine

Vacuum Plodder

Get Price Quote

Vacuum Plodder, Soap Bar Cutter, Soap Crutcher, Soap Flaker

Twin Worm Duplex Vacuum Plodder

Get Price Quote

Twin Worm Duplex Vacuum Plodder, Sigma Mixer, Laundry Plant

Vacuum Plodder

Get Price Quote

Vacuum Plodder, Cage Mill, Soap Flaker, Sigma Mixer

Duplex Vacuum Plodder

Get Price Quote

Duplex Vacuum Plodder

Duplex Plodder

Get Price Quote

Duplex Plodder, Tripple Roll Mill, Mixer, Soap Machines, Soap Plant