Oil Filter

135,000 Per piece

1 k (MOQ)

Centrifugal Blowers

Get Price Quote

From Ahmedabad(India), India, we delight our valuable patrons by providing quality-centralized products. We cater to the personalized packaging requirements of the clients. We make use of premium packing material for ensuring safety of the products during handling, warehousing and transportation. Overview : Fiberglas Reinforced Plastic (FRP) centrifugal blower assembly, manufactured using high quality corrosion resistant resins and fiberglass reinforcing able to withstand temperatures 120 deg.Design Features : Housings are rotatable in increments and have round inlets and outlets, facilitating quick installation to round ducts.Housings are rotatable in increments and have round inlets and outlets, facilitating quick installation to round ducts. Impeller is a self cleaning curved radial tip design allowing for stability at high S.P. and at low to medium flow rates, dynamically balanced. Fan supports are manufactured of structurally formed or structural steel and coated with baked epoxy polyester. Arrangement : Standard belt drive allows for a compact footprint when space is an issue, such as mechanical rooms with multiple fans Belt drive is available for larger motors and special designs. Direct drive supplied as standard with an FRP stand. Blower Parts : Casing Impeller Shafting Motor Belt Inlet Cone Stand

Best Deals from Dust Collector Parts

Pulse Jet Dust Collector

Get Price Quote

1 Nos (MOQ)

Design features : The blower unit of dust collector is dynamically balanced. The non-overloading, backward inclined fan system delivers more air at higher static Pressures and reduces capacity variation and suction loss. The dust collector is fabricated in modular design and all the joints are sealed with imported sealing compound. Type of filters used in pulse jet type dust collectors : Spun bounded pleated cartridges type filters Non-wooven polyestor type filters with cage type arrangement Type of dust removal arrangements for dust collectors : Mechanical type flap valve Rotary/airlock valves.

Coupling Driven Centrifugal Blower

45,000 - 85,000 Per piece

1 piece (MOQ)

capacity : 2000 cfm to up pressure : 60 mm to 1200 mm rpm :1440, 2880 drive : couple drive power : 415 v material : m.s, s s 304,316 blade : backward curved, backward inclined application : fresh air, cooling.

Industrial Dust Collector System

Get Price Quote

1 Piece (MOQ)

Masala machine 3HP with cyclone

180,500 - 180,700 Per Piece

1 Piece (MOQ)

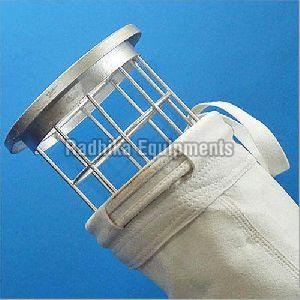

Dust Filter Bag Cage

Get Price Quote

20 Piece (MOQ)

Bag Handling System

Get Price Quote

We are enlisted among the distinguished Manufacturers, Suppliers and Exporters of Bag Handling System. The systems offered by us are used to convey items like sugar bags, cement bags, chemical bags etc. These are fabricated as per the specific requirements of the buyers by our team. Stay assured, we offer these at nominal rates.

Filter Cages

400 - 800 Per Piece

10 Piece (MOQ)

Construction :Filter cages are available in various grade in steel. Black wire (MS), GI (Galvanized) Stainless Steel (SS304 ,316, 316 L etc.Features : Very economical and strong retaining capacity. Low consumption of compressed air (for cleaning) Reduction in downtime & maintenance Easy to install & remove Durable

baghouse filter

Get Price Quote

Features: Reliable Sturdy construction Long lasting

STAINLESS STEEL FILTER BAG CAGE

1,200 Per Piece

1000 Piece (MOQ)

Ptfe Filter Bag

Get Price Quote

10 Piece (MOQ)

Pocket Polyester Bag Filters

3,000 Per Piece

12 Piece(s) (MOQ)

cyclone filter rasper machine

Get Price Quote

Fret not! We are flexible enough in delivering the products safely and this is done using the exceptional packaging material. We keep in mind the packaging guidelines to make sure that the products are safe from external destructive factors. A capacious warehouse and well-organized Warehouse Management System helps us in loading and unloading of all the products within short time. We keep our inventory updated by recording warehouse transactions and delivery of goods.

Air Blower

1,250 - 6,000 Per Piece

1 Piece (MOQ)

Polyester Filter Bag

400 Per Piece

Screw Blower

Get Price Quote

1 Piece (MOQ)

VN 40 Dust Collector Machine

Get Price Quote

5 Piece (MOQ)

Filter Bag

Get Price Quote

Dust Collector Bags

200 Per Piece

1 Piece(s) (MOQ)

dust control system

65,000 Per Piece

1 Piece (MOQ)

Extended Life Filter Bags

Get Price Quote

About Extended Life Filter Bags (POEX/PEEX)The Extended Life filter bags (POEX and PEEX) provide outstanding performance on many types of contaminants such as gels, particles with wide ranges of sizes, and particles with various irregular shapes. The coarse, pre-filtering layer is designed to provide long service life, capturing a large amount of contaminants without excess surface loading. The POEX has been field-proven to hold up to twice the amount of contaminants as a standard felt bag, reducing waste volume and bag changes. The Extended Life filter bag is ideal for automotive coatings, chemicals, resins, edible oils and other fluid applications.Features Excellent filtration on many contaminants - gels, particles with wide range of sizes and particles with irregular shapes A coarse inner layer, graded pore structure, greater depth than standard bags provides excellent filtration performance Available in polyester (PEEX) and polypropylene (POEX) Twice the standard dirt-holding capacity of traditional felt bags to provide longer service life, fewer change-outs and reduced waste Polypropylene bags are FDA compliant Micron rating for polypropylene 5-100; polyester 1-100 PolyWeld® seam construction with hermetically sealing Polyloc® ring eliminates liquid bypass Glazed finish eliminates unwanted fiber migration

CENTRIFUGAL EXHAUST BLOWER

45,500 Per piece

1 Piece (MOQ)

Industrial filter bag

Get Price Quote

We are main supplier of this product.

Dust collector filter bag

Get Price Quote

Dust Collector

25,000 Per unit

Oil Filters Bag

300 - 660 Per Piece

10 Piece(s) (MOQ)

CNC Router Dust Collector

28,000 Per Piece

1 Piece (MOQ)

PP Liquid Filter bag

Get Price Quote

100 Piece (MOQ)

Filter Bags Filter Bags are cylindrical or tubular fabric-based devices used for the filtration of liquids in a wide range of industrial applications. They are an essential component of bag filter systems, which are employed to remove solid particles and contaminants from liquids. Here's an overview of filter bags, their types, materials, and common applications: Types of Filter Bags: Liquid Filter Bags: These are designed for the filtration of liquids, including water, oils, chemicals, and more. They are commonly used in industrial processes and various filtration systems. Dust Collector Bags: These filter bags are used in dust collection systems to capture and contain dust and particulate matter. They are widely used in woodworking, metalworking, and other industries with dust-producing operations. Materials for Filter Bags: Filter bags are typically made from various materials, each suited for specific applications: Polypropylene (PP): Commonly used for general-purpose applications, polypropylene filter bags offer good chemical resistance and are cost-effective. Polyester (PE): Polyester bags are known for their strength, dimensional stability, and resistance to abrasion. They are often used for applications with higher operating temperatures. Nylon (PA): Nylon filter bags are suitable for applications requiring high tensile strength and resistance to organic solvents. They are commonly used in the food and beverage industry. PTFE (Polytetrafluoroethylene): PTFE bags are ideal for applications requiring chemical resistance to aggressive liquids and high-temperature resistance. They are commonly used in pharmaceutical and chemical industries. Aramid (Nomex and Conex): Aramid filter bags, such as Nomex and Conex, are known for their exceptional heat resistance and are used in applications involving high-temperature gases. Common Applications: Filter bags find widespread use in various industries, including: Water Treatment: Municipal and industrial water treatment plants use filter bags to remove sediment, particulates, and contaminants from water. Oil Filtration: In the oil and gas industry, filter bags are used to filter crude oil, lubricating oils, and hydraulic fluids to remove impurities. Chemical Processing: Chemical plants use filter bags to filter chemicals and solvents, ensuring product quality and preventing contamination. Food and Beverage: Filter bags are used for filtering beverages like beer, wine, and fruit juices, as well as in dairy and food processing. Pharmaceuticals: The pharmaceutical industry relies on filter bags for sterile filtration to maintain product purity. Metalworking: In metalworking operations, filter bags in dust collection systems capture metal dust and particles to improve air quality and worker safety. Power Generation: Power plants use filter bags for emissions control, particularly in coal-fired power plants to capture particulate matter. Agriculture: Filter bags are used in agricultural applications to filter irrigation water and control sediment in runoff. Chemical Manufacturing: Chemical manufacturers use filter bags to separate solids from liquid chemicals during various production processes. Paints and Coatings: Filter bags are used to remove contaminants and ensure the quality of paints, coatings, and ink formulations. Filter bags come in various sizes, micron ratings, and configurations to meet specific filtration requirements. Choosing the right filter bag material and design is crucial to ensure efficient and effective filtration in diverse industrial settings.

Dust Collector

35,000 Per Piece

1 Piece (MOQ)