Eddy Current Testing Training Services

Get Price Quote

Our Eddy Current Testing Training Services offer comprehensive instruction for professionals seeking expertise in this advanced non-destructive testing method. Through a combination of theoretical knowledge and hands-on practical exercises, participants learn to effectively utilize eddy currents to detect surface and subsurface defects in conductive materials. Led by experienced instructors and utilizing cutting-edge equipment, our training equips individuals with the skills necessary to perform accurate and reliable inspections in industries such as aerospace, automotive, and manufacturing. Trust us to elevate your team's capabilities in eddy current testing, ensuring quality and safety in your operations.

Eddy Current Testing

12,000 Per Day

We have reached the pinnacle of success and earned a reputed name by providing the high-quality Eddy Current Tube Inspection Service.Offered service is widely demanded by our clients owing to its high reliability and perfect execution. This service is carried out under the supervision of our experts using optimum grade tools and high-end technology. Our professionals check all the steps related to this service and execute it in an excellent manner. Moreover, our precious clients can avail this service from us at most reasonable price.

Looking for Eddy Current Testing Service Providers

Eddy Current Crack testing Service

Get Price Quote

Trinity NDT is your trusted provider of Eddy Current Testing (ECT) services, specializing in the detection of cracks and material defects in a wide range of industries. We are dedicated to ensuring the integrity and safety of critical components and materials through our advanced ECT solutions. Our Eddy Current Testing Services Include: Crack Detection: We utilize high-frequency alternating current to inspect conductive materials, identifying surface and subsurface cracks, corrosion, and other imperfections with precision. Material Sorting and Conductivity Assessment: Trinity NDT can assist you in evaluating material properties, sorting materials, and ensuring quality control in manufacturing processes. Automated Testing: Our state-of-the-art equipment and automated testing solutions provide efficient and accurate inspections, reducing downtime and costs. Customized Services: We tailor our Eddy Current Testing services to suit the specific requirements of your project, offering flexibility and personalized solutions. Industry Expertise: With experience in industries like aerospace, automotive, power generation, and more, Trinity NDT is well-equipped to address diverse testing needs. We adhere to stringent quality and safety standards to guarantee the utmost accuracy and reliability in our Eddy Current Testing services. At Trinity NDT, we take pride in contributing to the safety and performance of your projects. Contact us today to learn how Trinity NDT's Eddy Current Testing services can enhance the quality and safety of your materials and components.

Eddy Current Testing Services

Get Price Quote

This ndt method is based on the principles of electromagnetic induction. The flow of electricity, under certain circumstances, can cause magnetism. Magnetism under certain circumstances causes the flow of electricity. When an alternating current (ac) is passed through a coil, a changing magnetic field is generated. This method can be applied to tubing, sheets, cylinders and coatings and provides a means for measuring conductivity, detecting discontinuities, and determining the thickness of coating or plating on articles. Since a continuous indication is a part of the basic testing system, automatic production testing is particularly feasible.

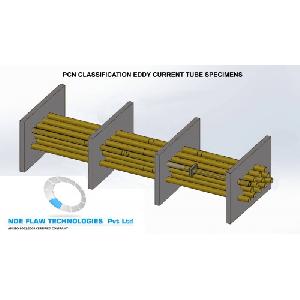

EDDY CURRENT TUBE BUNDLE SPECIMENS

700 Per Piece

1 Piece(s) (MOQ)

Pcn classification eddy current tube bundle specimens tubes in each bundle is 13 no�s, for training 6 bundle�s, for examinations 12 bundle�s, total 18 bundles 3 no�s cupro-nickel bundles for training 3 no�s aluminum brass bundles for training 6 no�s cupro-nickel bundles for examinations 6no�s aluminum brass bundles for examinations materials: 1. Amplitude analysis test � 7030 cupro-nickel of the following composition. Cu 66%; ni 30%; fe 2%; mn 2% 2. Phase analysis test � brass tubing of the following composition. Cu 76%; al 2%; as 0.04%; zn reminder tube dimensions, length thickness outer diameter and artificial flaws as per pcn requirements.

Eddy Current Testing

Get Price Quote

Eddy-current testing (also commonly seen as eddy current testing and ECT) is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials.

eddy current testing service

Get Price Quote

Eddy current testing continuous wave eddy current testing is one of several non-destructive testing methods that use the electromagnetism principle. Conventional eddy current testing utilises electromagnetic induction to detect discontinuities in conductive materials. A specially designed coil energised with alternating current is placed in proximity to the test surface generating changing magnetic-field which interacts with the test-part producing eddy current in the vicinity. Variations in the changing phases and magnitude of these eddy currents is then monitored through the use of receiver-coil(s), or by measuring changes to the alternate current flowing in the primary excitation-coil. The electrical conductivity variations or magnetic permeability of the test-part, or the presence of any discontinuities, will cause a change in eddy current and a corresponding change in phases and amplitude of the measured current. the changes are shown on a screen for easy interpretation. Another method of using the eddy current principle is pulsed eddy current testing. methods are being developed to investigate surfaces through protective coatings, weather sheetings, corrosion products and even the insulation materials. Inspection of surfaces at high temperature are possible with the eddy current technique as it is a non-contact method.

eddy current testing service

Get Price Quote

Eddy-current testing (also commonly seen as eddy current testing and ECT) is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials. The two major applications of eddy current testing are surface inspection and tubing inspections. Surface inspection is used extensively in the aerospace industry, but also in the petrochemical industry. The technique is very sensitive and can detect tight cracks. Surface inspection can be performed both on ferromagnetic and non-ferromagnetic materials

Eddy Current Testing Services

Get Price Quote

Eddy current testing is performed on non-ferromagnetic materials for surface and sub surface discontinuities, and on ferromagnetic materials for surface breaking discontinuities in accordance with ASME V, BS EN 1711, AS4544 and other Standards. Eddy current testing electrical currents are generated a conductive material by an induced magnetic field. Distortions in the flow of the electric current (eddy currents) caused by imperfections or changes in a materials conductive properties will cause changes in the induced magnetic field. These changes, when detected, indicate the presence of the imperfection or change in the test material.

Eddy Current Testing Machine Repair Service

Get Price Quote

Eddy Current Testing Machine Repair Service, Lemo Connectors Cables

Eddy Current Testing Services

Get Price Quote

One of the leading services company, providing many types of services like eddy current testing services

Eddy Current Testing

Get Price Quote

We are providing eddy current testing services. Crack detectors coating thickness conductivity testing find out the all surface defects to test the bolt hole wire rope testing rail, aircraft, ship and pipe line testing

Eddy Current Testing Services

Get Price Quote

Eddy current testing a modern Nondestructive testing – NDT method that has become one of the primetool for quality control of products, materials and structures at various stages of manufacturing and in-service inspections. Eddy current inspection can be used to find finest surface and subsurface flaws in any conductive material. Spectrums of quality control engineering applications are existing applying Eddy current principles. PresentEddy current NDT method has applications in Aerospace Component Inspections, Heat exchanger tube inspections and other critical engineering applications.

Eddy Current Testing

Get Price Quote

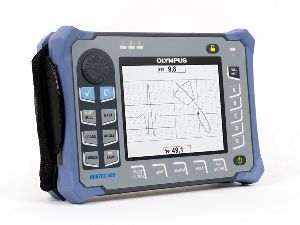

Test Instrument Capabilities Test channel (coilprobe support) Miz-23-One probecoil(pairs) at one frequency InSite HT- Up to eight coil (pair) at up to eight test frequencies.(64 data channels) InSite CT-Up to eight probes at no more than twotest frequencies.(16 data channels)

Eddy Current Testing

Get Price Quote

Eddy Current Testing

eddy current testing service

Get Price Quote

eddy current testing service, Parallel Thread Rebar Coupler

Eddy Current Testing

Get Price Quote

Eddy Current Testing, HACCP, Visual Inspection Testing Service

Eddy Current Testing Services

Get Price Quote

Eddy Current Testing Services, QA / QC Course, QA / QC Training, Mechanical

Eddy Current Testing Services

Get Price Quote

Eddy Current Testing Services, Third Party Inspection Services

Eddy Current Testing

Get Price Quote

Eddy Current Testing, Eddy Current Tester, visual inspection service