1 MLD Automatic Effluent Treatment Plant

12,850,000 Per Set

1 Set (MOQ)

sludge dewatering machine

300,000 Per Piece

1 Piece(s) (MOQ)

Best Deals from Effluent Treatment Plant

Wastewater Treatment Plant for Reuse

Get Price Quote

1 Piece (MOQ)

Wastewater Treatment Equipment

25,000 - 150,000 Per Piece

We offer wide range of advanced filtration systems that enables treatment of suspended particles, color, odour & oil through filtration. The media filters involved filtration of particulates across surface & depth of media. These systems are backwashed when the pressure drops across the media increase. Our range of filtration solutions includes: Gravity sand filter Rapid gravity sand filters Pressure sand filters Dual media filters Multimedia filters Auto valveless gravity filters Activated carbon filters Walnut shell carbon filters Micron filtration systems Micro filtration systems

Effluent Water Treatment Plant

800,000 Per Piece

1 Piece (MOQ)

A Wastewater Treatment Plant is a Facility Designed to Treat and Purify Contaminated Water From Industrial, Commercial, and Domestic Sources. The Primary Goal is to Remove Pollutants and Harmful Substances, Making the Water Safe for Discharge Into the Environment or Reuse. The Process Typically Involves Several Stages, Such as Preliminary Treatment, Primary Treatment, Secondary Treatment (Often Utilizing Biological Processes), and Tertiary Treatment for Further Purification.

Wastewater Treatment Plant for Sludge Treatment

Get Price Quote

To define and select an optimal sludge treatment we need to know : The sludge composition in relation to its origin The final destination of treated sewage sludge (recycling, recovery, destruction) The steady growth in the volume of sludge generated by water treatment, linked both to demographic change and the increasing urban sprawl, leads to increasingly tighter constraints for the municipalities.The treatment of sludge in order to reduce its volume and transform it into a recoverable product is now a necessity.To support local authorities in the management of sludge and by-products treatment, which must be recycled, eliminated or recovered, we offer various technical solutions which implement proprietary or licensed processes for : Sludge thickening and dewatering, Sludge digestion in order to reduce it in size, increased dryness through dewatering, long-term stabilization, and the recovery of green energy from sludge in the form of biogas, Thermal, mixed or solar drying, Destruction through incineration.

15 MLD Effluent Treatment Plant

Get Price Quote

1 piece (MOQ)

Effluent Treatment Plant

Get Price Quote

1 Piece (MOQ)

Liquid Overfeed System

Get Price Quote

We offer Liquid Overfeed System in different sizes as per the requirement in Ammonia Plant. Liquid Overfeed Systems (re-circulation system) are those in which excess liquid is forced, mechanically or by gas pressure, through organized-flow evaporators, separated from the vapor, and returned to the evaporators. This ensures no oil in the evaporators and no liquid slugs in the compressor leading to high saving in power and maintenance. We present carefully designed Liquid Overfeed System in domestic as well as international markets. Positioned as one of the leading Liquid Overfeed System Suppliers, we offer them at reasonable prices by us. Advantages Even refrigerant distribution Protection of compressors Hot gas defrosting No effects of fluctuating ambient and condensing conditions Zero pressure drops in the evaporators / overfeed lines Ease of operation Low maintenance Materials Used Steel Tube Pipe Channel Angle Seamless pipe Shell Laval gauge Liquid pump Valve flow control Attributes Compact design Power saver Fully automatic operation Truck size plant Easy transportation Applications Cold Storage Ammonia refrigeration plant

Effluent Treatment Plant

135,000 - 145,000 Per SET

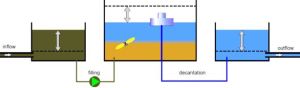

Effluent is generated in many manufacturing industries like textile, pharmaceuticals and chemicals, tanneries etc. Contaminated water cannot be released without treatment as it contains toxic and non-toxic chemicals. Releasing it may cause contamination of the existing pure water and will affect the environment. As a result ETP’s are installed in most manufacturing industries. The Effluent treatment plants (ETP) are used for the removal of high amounts of organic compounds, debris, dirt, grit, pollution, toxic, non-toxic materials and polymers etc. from industrial effluent. The ETP plants use evaporation and drying methods and other auxiliary techniques such as centrifuging, filtration , incineration for chemical processing and effluent treatment.ETP Plant Operation Screen Chamber : This chamber removes relatively large solid to avoid abrasion of mechanical equipment and clogging of hydraulic system. Collection Tank : The collection tank collects the effluent water from the screening chamber, stores and then pumps it to the equalization tank. Equalization Tank The effluents do not have similar concentration at all the time; the pH will vary time to time. Effluents are stored for up to 8 to 12 hours in an equalization tank resulting in the homogenous mixing of effluents and helping in neutralization. Continuous mixing also eliminates settling of solids within the equalization tank. Reduces SS, TSS.Flash mixer:- Coagulants are added to the effluents Lime:(800-1000 ppm) To correct the pH upto8-9 Alum: (200-300 ppm) To remove colour Poly electrolyte : ( 0.2 ppm) to settle the suspended matters and reduce SS, TSS. The addition of the above chemicals by efficient rapid mixing facilitates homogeneous combination of flocculates to produce micro flocs. Clarriflocculator In the clarriflocculator the water is circulated continuously by a stirrer. Flocculation provides slow mixing that leads to the formation of macro flocs, which then settles in the clarifier zone. Overflowing water goes out to the aeration tank. The solid particles settle down, and are collected separately; this reduces SS, TSS. The settled solids i.e. primary sludge is pumped into sludge drying beds. Aeration Tank The effluent after clarification flows to an aeration tank for aerobic treatment. This tank is equipped with air blowers or diffusers using which air is passed through the tank. This air is required to maintain the desired dissolved oxygen (DO) level required for bacteria to grow and remove BOD and COD by breaking down the matter. BOD and COD values of effluent are reduced up to 90%. Secondary Clarifier The overflow from aeration tank is led into the secondary clarifier where solid liquid separation takes place. The settled solids in secondary clarifier are called biological sludge, a part of which is recycled back into the aeration tank to maintain the desired MLSS level and remaining sludge is conveyed to sludge collection tank for further treatment. The outlet water quality is checked if it’s within the accepted. The treated water is disposed through pipelines. Sludge Thickener The inlet sludge consists of 60% water + 40% solids. The effluent is passed through a centrifuge. Due to centrifugal action, the solids and liquids are separated. The sludge thickener reduces the water content in the effluent to 40% water + 60% solids. The effluent is then reprocessed and the sludge is collected at the bottom. Drying BedsPrimary and secondary sludge is dried on the drying beds to further reduce the water content.

10 KL Effluent Treatment Plant

Get Price Quote

Effluent Treatment Plant

500,000 - 2 Per Set

1 Set (MOQ)

Sequential Batch Reactor

Get Price Quote

1 Piece (MOQ)

SBR type STP works on the principle of batch treatment of the sewage. Sewage is collected & fed to the reactor in 4 or 5 batches. Air is supplied & the completed aerobic process takes 2 hrs per batch. Once aeration is finished, the sewage comes to a stand-still position so that all suspended solids settle at the bottom thus clarifying the water. Clarified water is then decanted out to be collected In the clarified water tank. This water is further disim fected, filtered & stored or drained. SBR has following features : » Automatic operation of the reactor controlled by a PLC. » Single Tank Operation. » No media addition / replacement. » Intermittent operation so less maintenance. » Low sludge yield, typically once in 10-12 days. » Possible In open, underground & basements. » Water can be reused for gardening & flushing

Wastewater Treatment Plant

Get Price Quote

Enlisted amidst the renowned Suppliers of Wastewater Treatment Plant, we cater to varied demand of the customers in this sphere. By guaranteeing complete security of the products, we make sure that our buyers remain satisfied with us. For this, we store the entire lot in our state-of-the-art warehouse.

Industrial Effluent Treatment Plant

95,000 - 450,000 Per Set

1 Unit (MOQ)

Waste Water Treatment Plant For MDF Board

500,000 Per piece

1 piece (MOQ)

Effluent Treatment Plant

30,000 - 800,000 Per piece

1 Piece (MOQ)

Sewage Wastewater Treatment Plant

Get Price Quote

1 Piece (MOQ)

Sewage Wastewater Treatment Plant

1,235,000 Per Piece

1 Piece (MOQ)

Waste Water Treatment Plant

2,000,000 - 10,000,000 Per Per no.of plant

1 Unit (MOQ)

A wastewater treatment plant is a facility in which a combination of various processes (e.g., physical, chemical and biological) are used to treat industrial wastewater and remove pollutants. Price will be depends on Capacity of Plant.

Effluent Sewage Treatment Plant

Get Price Quote

1 Piece (MOQ)

Wastewater Treatment Plant

75,000 Per Piece

1 Piece (MOQ)

effluent water treatment plants

310,000 Per Units

Effluent Treatment Plant

Get Price Quote

we manufacture effluent treatment plant which is beneficial for handling various industrial effluents generates due to industrial use. Our range of effluent treatment plants are designed in compliance with the prevailing industry standards, hence are ideal for controlling industrial effluent originating from all type of industries. applications chemical units paper industry textile processing industry parboiled rice mill metal processing industries slaughter house cocovens coal washeries pharmaceutical thermal power plants any industry generating industrial effluents salient features high output easy to maintain high performance long operational life corrosion resistance safe and reliable low power consumption sturdy construction low maintenance

Effluent Treatment Plant

198,000 - 1,000,000 Per Set

1 Set (MOQ)

Effluent Treatment Plant

10,000 - 10,000,000 Per Set

1 Set (MOQ)

Compact ETP Plant

Get Price Quote

1 Piece (MOQ)

HESPL is specialized in to build a compact ETP plants based on green building concepts. As because of We are the leading Effluent Treatment Plant Manufacturer of Bhubaneswar Odisha India, We Manufacturer bulk quantity of Compact Effluent Treatment Plants also. These plants are based on sustainable & environment friendly technologies. Our well trained professionals assure that these products are in accordance with the international standards of quality. Offered products are extremely valued by our esteemed clients for their compact design, user friendly, durability, low maintenance, corrosion resistance and longer service life features. In order to meet the varied requirements of clients, these products are provided in both, standards and customized forms. We are offering wide range of Effluent treatment Plants ranging from KLD to MLD based on requirements, which competes all the pollution boards government norms

Effluent Water Treatment Plant

Get Price Quote

1 Unit (MOQ)

Effluent Treatment Plant

Get Price Quote

1 Piece (MOQ)

100 KLD Effluent Treatment Plant

250,000 Per Unit

1 Unit (MOQ)