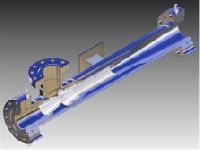

ejector compressor

Get Price Quote

The efficiency of a Steam-turbine is mainly determined by the pressure of the steam at its outlet. The Turbine Surface Condenser is therefore maintained under vacuum. To enable this, the Steam Jet Ejector Vacuum System must be capable of removing all non condensable and associated water vapour from the Surface Condenser to produce the minimum steam condensing pressure consistent with physical dimensions and heat transfer and to provide for deaeration of the condensate. The sources of non condensables include air leakage through all system components operating below atmospheric pressure, gases released from feedwater drains and vents admitted to the condenser, gases released for make-up admitted to the condenser, condensate surge tank when utilized in a closed cycle and disassociation of feedwater into oxygen, hydrogen and non condensables.

ejector compressor

Get Price Quote

Gas jet ventilators are devices based on the jet venturi principle which are used to produce large suction flows at low vacuum levels.Suction flows in multiples of the motive flow can be obtained in gas jet ventilators.

Best Deals from Ejector Compressor

Billet Ejector

Get Price Quote

We are offering ejector. our impressive range of billet ejector is classified in various technical specifications as per the requirements of the clients. The double stand hydraulic billet ejector, available with us, is developed to install in the façade of furnace. It ejects hot ingot that is meant for rolling in the furnace. However, we are widely acknowledged as one of the most prominent hydrolic pusher billet ejector exporters in the country.

jet ejector

Get Price Quote

Ideal for plants with highly polluted waste water In its construction form the ejector for the aeration process corresponds to that of a jet ejector. Because organically polluted wastewater requires a high amount of oxygen and also because of the increasing height of modern biological waste water cleaning plants it is energetically more efficient to pre-compress the air mechanically to the hydrostatic pressure prevailing at the installation point of the ejector and to supply it so to the suction connection. This waiving of an appreciable pressure in the ejector reduces the necessary motive pressure. At the same time, more favourable mixing ratios (suction flow : motive flow) are achieved. Motive nozzles of Hatco ejectors are equipped with a non-clogging spiral. So the motive jet disperses the air already at a low motive pressure in a myriad of fine bubbles which are then mixed vigorously together with the motive flow in the mixing zone. This air/water mixture is injected into the aeration tank with a high turbulence. In this way the ejector guarantees optimum oxygen supply and a total intermixing of the tank contents. Even with a high biomass concentration in the waste water it is still possible to attain flow velocities which prevent deposits on the tank floor. Advantages of Hatco’s ejectors:- Maintenance-free – no moving elements High oxygen efficiency – Fine bubbles create large contact surfaces between air and water and high turbulence renews these contact surfaces. No deposits – The intensive jet flow directed towards the tank floor prevents deposits of biomass. Straightforward control of oxygen supply Non-clogging construction – The nozzle diameter defines the narrowest flow cross-section. No sealing problems – When the plant is inactive, water can enter the air pipeline without negative effects and when re-started, the ejector’s entraining effect expels any liquid in the pipe. Design acc. to requirements – Various sizes can be designed and adapted to requirements.

ejector compressor

Get Price Quote

Ejectors compressor create broad spectrum noise with distinct peaks at frequencies related to the motive stream nozzle dimensions. The noise levels generated by the high pressure ratios across the motive stream nozzle, can reach very high levels inside the pipe which, if left untreated may cause acoustic fatigue damage to the downstream pipework as well as exceeding local noise levels requirements for personel protection. Designed for the short acoustic wave lengths produced by motive steam noise, each silencer is custom engineered using a computer program developed by Flo-Dyne. The program enables Flo-Dyne to match the silencer components, the packing, the passage with perforated acoustic facings to the acoustic and flow characteristics of the system.

Industrial Ejector

Get Price Quote

Pneucon Ejector products are quality derived in a fashion that makes the products viable as well as modern. We manufacture varieties of ejector products and from various materials. All our products have a set of standard quality measures and that is always at par with international standards. Product Specification Our products are compact, corrosion resistant and can be used in any suitable manner. We manufacture ejectors based on the client's need as well as most common necessities and so for different uses we use different materials. Extremely light and super strong ejectors are made from carbon, PVC, Rubber, and Teflon materials. For underground and other heavy purpose ejectors we use cast steel, cast iron, and stainless steel materials. We have varieties of vacuum ejectors, water ejectors and steam ejectors. All of our ejectors are easy to install and operate. With flexible pricing we make sure that it is affordable for all needs. Order Type : Individual and Company, Retail and Bulk, and readymade as well as custom made. We ensure the durability and value for money with each and every single piece of our product.

ejector compressor

Get Price Quote

ejector compressor, Boiler Tubes, Industrial Valve, Gaskets

ejector compressor

Get Price Quote

ejector compressor

ejector compressors

Get Price Quote

ejector compressors, SS CHEMICAL REACTOR, chemical vaporizer

ejector compressor

Get Price Quote

ejector compressor, Hardware Products, Electronic Equipment