Elastomeric Bearing Pad

0 - 1 Per Cubic Centimeter

Elastomeric bridge bearings are components used in the construction of bridges to accommodate movement and provide support between different structural elements. These bearings are made of elastomeric materials, such as natural rubber or synthetic rubber compounds, which possess excellent elastic properties. The primary purpose of elastomeric bridge bearings is to transfer loads from the bridge superstructure to the bridge substructure while allowing for various types of movements, including rotation, translation, and rotation. These movements can occur due to factors such as thermal expansion and contraction, seismic activity, and traffic-induced vibrations. Here are some key features and benefits of elastomeric bridge bearings: 1. Load Transfer: Elastomeric bearings distribute the load from the bridge deck to the piers or abutments, reducing stress concentrations and ensuring even load distribution. They can handle vertical, horizontal, and rotational forces effectively. 2. Vibration and Shock Absorption: Elastomeric materials have excellent damping properties, allowing them to absorb and dissipate energy from dynamic forces, such as traffic vibrations and seismic activity. This helps in reducing the transmission of vibrations to the bridge superstructure and enhances overall bridge performance. 3. Movement Accommodation: Elastomeric bearings can accommodate both translational and rotational movements of the bridge superstructure. They allow for expansion and contraction due to temperature changes, as well as movements caused by seismic events or live loads. 4. Durability and Longevity: Elastomeric materials used in bridge bearings are designed to withstand harsh environmental conditions, including exposure to ultraviolet (UV) radiation, moisture, and temperature variations. They have good resistance to aging, weathering, and chemical degradation, ensuring the longevity of the bridge bearings. 5. Low Maintenance: Elastomeric bearings require minimal maintenance compared to other types of bridge bearings. Their robust design and durability reduce the need for frequent inspections and repairs, resulting in cost savings over the life of the bridge. It's important to note that specific design and installation guidelines must be followed while incorporating elastomeric bridge bearings into a bridge project. These guidelines ensure that the bearings are properly sized, positioned, and installed to provide optimal performance and safety. Overall, elastomeric bridge bearings play a crucial role in the construction and functionality of bridges by accommodating movements, reducing stress, and enhancing the overall structural integrity.

Elastomeric Neoprene Bearing Pads

70 - 80 Per ccm

20 Piece (MOQ)

Best Deals from Elastomeric Bearing Pad

Elastomeric bearing pads

Get Price Quote

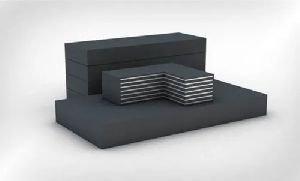

Elastomeric bridge bearing Pads are commonly used for bridge bearing. There are several different types of bridge bearings that include neoprene bearing pads, Steel laminated elastomeric bearings, etc. These are all generally referred to as bridge bearing pads in the construction industry. Internal structure consists of a sandwich of mild steel plates and rubber, moulded as one unit. Elastomeric bearing pads compress on vertical load and accommodate horizontal rotation and lateral shear movement. Elastomeric bearing pads are the most economical solution used in construction of large span bridges and buildings. Elastomeric Bearing pads can resist the vibrations from the earth.

Elastomeric bearing pads

1,600 Per Piece

10 Piece (MOQ)

Neoprene Elastomeric Bearing Pads

Get Price Quote

Our company is one of the prominent Manufacturers, Exporters and Suppliers of as wide range of Neoprene Elastomeric Bearing Pads. They permit a smooth and uniform transfer of load from the beam to substructure and allow beam rotation at the bearing due to deflection of beam under load. Due to thermal expansion and contraction movement of the beam is allowed by bearing pads. Buyers can purchase Neoprene Elastomeric Bearing Pads from us at market leading prices. We offer them in varied specifications. Types Available : Neoprene EPDM Silicone Known for : Easy installation Resistance to chemicals and weather Custom-made designs Dimensional accuracy High elasticity Resistance to high/low temperature and pressure Rubber Pads in all Colors and Sizes Packaging Materials : Corrugated boxes LDPE sheet Applications : Construction Industry Airport

Modified Elastomeric pad

1,500 Per Piece

500 Piece (MOQ)

Elastomeric bearing pads

Get Price Quote

Elastomeric Bearing Pad

15,000 Per Piece

Elastomeric bearing pads

Get Price Quote

Markings on concrete Rubber Moulds block surfaces have been done using traditional paint or thermoplastic materials. Maintenance of these markings is difficult and costly. The frequency at which repainting has to be done is very high. Advantages of Rubber Moulds Pavers Block:- Consistency in dimensional tolerances Eliminates the need for re-painting Provide permanent markings for traffic Consistency in colour Practically maintenance free Available in different colours High strength units with integral reflective colouring Generally self – cleansing Clearly visible at night and in adverse weather

Modified Elastomeric pad

Get Price Quote

50 Piece (MOQ)

Elastomeric Bearing Pad

Get Price Quote

Elastomeric Bearing Pad

Get Price Quote

Elastomeric Bearing Structures are subjected to imperceptible displacements and rotations that have to be accommodated to protect the structure and surrounding infrastructure. The function of the bearing is to safely accommodate the various movements and rotations as well as supporting the weight of the structure and to transmit the load through to the structures foundation.

SUSPENSION CLIPPER WITH ELASTOMER PAD

Get Price Quote

Set of suspension clipper (made of aluminum alloy permanent mould die cast split type clamp) is used to support the elastomer pad inserts & is strapped by a galvanized steel eye-band in order to hang from a twisted eye-link connected to a pole mounted stay clamp or tension hook.

Elastomeric bearing pads

Get Price Quote

CORIRUBBER ® Elastomeric Bearing Pads Elastomeric Bridge Bearing Pads is a block of vulcanized elastomers reinforced internally by one or several steel plates, chemically bonded during vulcanization. . External Forces being supported Elastomeric bearings permit the simultaneous support of the following loads :. Absorption of briefly applied external horizontal forces Horizontal movement in all directions through shear deformation. Rotation of the bearing surfaces around all axes Standard absorption of vertical loads. Elastomeric bearings are made out of chloroprene polymer. These bearing pads are designed for used in bridges and other structures such as buildings as a vertical load bearing component. There are manufactured from high quality material with number of layers of steel plates depending on the type of bearings highly strong and extremely resistance to weathering, ageing with almost no influence from UV radiation and ozone. Neoprene bearing pads provide uniform transfer of load from beam to structure. They absorb vibration and prevent noise transfer. While reducing the destructive action of vibration between movable and stationery structural members. They permit beam rotation at the bearing point due to deflection or misalignment. May also provide for movement caused by normal expansion and contraction and concrete creep effects and shrinkage. These pads are extensively in bridge structures. These pads provide good resistance to traction, excellent failure strain and performs well with dynamic loads. It has good rear resistance, excellent resistance to aging and a very low load bearing creep rate. This makes it suitable for the requirements of bearings. Laminated Elastomeric Bearings Type A : Single reinforcement Bearing (Not used in civil Engineering structure). Type B : The definition for type B according to EN 1337-3 is ; this type has (n+1), reinforcement /metal and (n) elastomeric of constant thickness with perimeter at least 4 millimetres thick and the upper and lower faces with a nominal 2.5mm thickness of elastomeric. The tolerance is (-0 and +2). Other Type B : By definition these are different in that the upper and lower elastomeric coatings are thicker. This type of bearing is no longer straightforward reinforcement protected by elastomeric, but designed on the basis of required ability such as Elastomeric a Half Lamination or Passive Coating types. Type C : Elastomeric bearings with two external plates and threaded holes for use onmetal structures, or as an anti-lift device: in this latter case, suitable anchor bars must be fitted to the bearings for anchoring purposes. Type D : Elastomeric bearings with external plates and pins that connect to suitable steel plates in order to secure the bearing to the structure.. Type E : Elastomeric bearings with two suitably etched external plates to facilitate the bearing’s bonding to the structure by way of vulcanisation.

Elastomeric bearing pads

Get Price Quote

Elastomeric Bridge Bearing Pads is a block of vulcanized elastomers reinforced internally by one or several steel plates, chemically bonded during vulcanization. . External Forces being supported Elastomeric bearings permit the simultaneous support of the following loads :. Absorption of briefly applied external horizontal forces Horizontal movement in all directions through shear deformation. Rotation of the bearing surfaces around all axes Standard absorption of vertical loads. Elastomeric bearings are made out of chloroprene polymer. These bearing pads are designed for used in bridges and other structures such as buildings as a vertical load bearing component. There are manufactured from high quality material with number of layers of steel plates depending on the type of bearings highly strong and extremely resistance to weathering, ageing with almost no influence from UV radiation and ozone. Neoprene bearing pads provide uniform transfer of load from beam to structure. They absorb vibration and prevent noise transfer. While reducing the destructive action of vibration between movable and stationery structural members. They permit beam rotation at the bearing point due to deflection or misalignment. May also provide for movement caused by normal expansion and contraction and concrete creep effects and shrinkage. These pads are extensively in bridge structures. These pads provide good resistance to traction, excellent failure strain and performs well with dynamic loads. It has good rear resistance, excellent resistance to aging and a very low load bearing creep rate. This makes it suitable for the requirements of bearings. Laminated Elastomeric Bearings Type A : Single reinforcement Bearing (Not used in civil Engineering structure). Type B : The definition for type B according to EN 1337-3 is ; this type has (n+1), reinforcement /metal and (n) elastomeric of constant thickness with perimeter at least 4 millimetres thick and the upper and lower faces with a nominal 2.5mm thickness of elastomeric. The tolerance is (-0 and +2). Other Type B : By definition these are different in that the upper and lower elastomeric coatings are thicker. This type of bearing is no longer straightforward reinforcement protected by elastomeric, but designed on the basis of required ability such as Elastomeric a Half Lamination or Passive Coating types. Type C : Elastomeric bearings with two external plates and threaded holes for use onmetal structures, or as an anti-lift device: in this latter case, suitable anchor bars must be fitted to the bearings for anchoring purposes. Type D : Elastomeric bearings with external plates and pins that connect to suitable steel plates in order to secure the bearing to the structure.. Type E : Elastomeric bearings with two suitably etched external plates to facilitate the bearing’s bonding to the structure by way of vulcanisation.

elastomeric bridge bearing pad

Get Price Quote

elastomeric bridge bearing pad, Expansion Joint Filler Board

elastomeric bridge bearing pads

Get Price Quote

elastomeric bridge bearing pads, Conveyor belts, Expansion Joint Filler Board

Elastomeric Bearing Pad

Get Price Quote

Elastomeric Bearing Pad, PTFE Seals Bellows, Rubber Bellows

Elastomeric bearing pads

Get Price Quote

Elastomeric bearing pads, dock bumper, rubber tyre, Rubber Mat, Rubber bush

elastomeric bridge bearing pads

Get Price Quote

elastomeric bridge bearing pads, Pot Bearings, Vibration Mount, cage mat