Electrical Discharge Machine

Get Price Quote

We are offering our entire range of products in excellent quality packaging to guarantee zero damage during transit. For this, we have hired only professional packing personnel to ensure the same. Courtesy a state-of-the-art warehousing unit and an ultramodern inventory control system, we take care of product storage related work with ease. Our warehouse and system empowers us to maintain year round products' availability.

Electric Discharge Sawing Machine

Get Price Quote

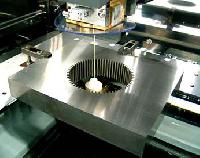

we are listed among the most reputed electrical discharge sawing machine manufacturers and suppliers from pune. our electric discharge sawing machines can easily cut through electrically conductive materials irrespective of its hardness. the electrical discharge sawing machine provided by us is made from quality raw materials, which offer its durability and strength. features :- it can cut any electrically conductive material irrespective of its hardnesssawing of spherical or slanting surfacesfaster than band saw in case of hard materialsminimum loss of material, as the cutting width is less than 1.5mmno deformation of work piecegood sawing efficiency irrespective of hardness & resistant strengthonly small zone gets affected due to heat generationvery low running expenses click here for more details technical specifications :- machine tooleds200eds400eds600eds1000maximum cutting limits (cross-section of work piece) 200mm x 200mm400mm x 400mm600mm x 600mm1400mm x 1000mmwork table dimensions400mm x 600 mm600mm x 800 mm800mm x 800 mm1400mm x 1000mmlongitudinal travel (y)600mm600mm600mmnavertical saw travel (z)250mm450mm650mm1150mmrapid free rate600mm/min600mm/min600mm/min600mm/mincutting (working) saw servo feed40mm/min40mm/min40mm/min40mm/minaverage cutting speed10 -15cm2/min10 -15cm2/min10 -15cm2/min10 -15cm2/minsaw speed 16m/sec16m/sec16m/sec16m/sectension on saw belt300kg300kg300kg300kgelectrode material--mild steel-axis measurement y & z with encoder0.005mm0.005mm0.005mm0.005mmnet weight4500kg5000kg6000kg1000kgmachine tooleds200eds400eds600eds1000maximum output30 v, 200 a30 v, 400 a three stages change30 v, 400 a 30 v, 800 a output amperage adjustment methodsaturated reactor typeelectrode servo feeding methoddc servo type (ac servo optional)input power supply* 3 phase, ac, 415 v, 50 hz*connected load20 kva45 kva45 kva140 kva note :- alternate power supply rating available on request.

Best Deals from Electrical Discharge Machine

EDM - Spark Erosion Machine

Get Price Quote

EDM (Electric Discharge Machine) mainly used for manufacturing of dies & moulds. EDM used for wire cut, spark erossion, die sink, metal dinegration, drilling, tapping, marking & branding etc. FEATURES : • Universal Axis Corrector • X & Y With Needle Roller Bearings Along With Ball Screws. • Z Axis With Precisily Ground Quill & Rail Pair With Harden & Ground Lead Screw. • Very Compact Models. • Conventional & ZNC Controllers With 20, 35 AMP. • Very High MRR. • Less Than 0.1% Wear. • Surface Finish 0.7 pRa. • Indigenously Designed and Developed Controller. • 3 Axis DRO Standard Feature.

E Rickshaw DC Converters

80 Per Piece

Electric Discharge Sawing Machine

Get Price Quote

EDS 200, EDS 400, EDS 600 & EDS 1000 After extensive R & D for the past 30 years in the field of Electric Discharge Machining, now Electronica is introducing High-Speed Sawing Machines using the Electric Discharge principle for cutting all metals, including exotic ones.Ideal for Aeronautical Engineering, Metallurgical and Research laboratories, Defence workshops.How it worksAn endless Mild Steel belt is used as an electrode to cut the workpiece. This Mild Steel belt rotates continuously over the two pulleys under tension. The thickness of this Mild Steel belt ranges between 0.5 and 0.9 mm and has the width between 19 and 40 mm and the length approximately 7500 mm.This electrode is fed to the workpiece with the help of Servo system. Water-based diluted Silicic acid soda (Sodium Silicate) solution or distilled water is used as dielectric. Performance Maximum cutting speed : 10 to 30 cm The cutting speed is calculated considering the cross section the workpiece that is to be cut. For example, to cut a slice out of square bar of 10 cm x 10 cm it will require roughly 10Depth of the heat-affected zone on the sawing surface : < 0.5 mm Applications Sawing of hard metals & exotic metals such as Titanium, Stainless Steel, Super Alloy, Inconel, Cast Steel etc. Sawing of fragile or soft materials, honeycomb, thin pipes etc. Works on all types of metals used in Aeronautical Engineering Most suitable for sawing materials such as, Tool Steel, Super Heat-resistant Alloy, Stainless Steel, Cast Iron and Cast Steel Advantages It can cut any electrically conductive material irrespective of its hardness. Sawing of spherical or slanting surface. Faster than band saw in case of hard materials. Minimum loss of material, as the cutting width is less than 1.5 mm. No deformation of the workpiece. Good sawing efficiency irrespective of the hardness and resistance strength. Only a small zone gets affected due to heat generation. Easy clamping due to very small sawing resistance which is 300 to 500 gm per sawing width of 10 mm. Very low running expenses. Operational Features Automatic belt tension adjusting system with a sensor in case of belt elongation. It is interlocked with the process to ensure cutting with higher efficiency. Pneumatic job-clamping system (optional) This clamping system is separate from the worktable. Hence, a continuous cutting and feeding is ensured without loss of time in clamping the workpiece. Motorised trolley / roller conveyor (optional) for continuous feeding of the workpiece for cutting Motorised Y axis movement (optional) with position feedback, allows precise positioning of the workpiece Y axis movement is disabled during the cutting operation, ensuring trouble-free cutting Separate strip butt welding system with built-in grinder, allows instant welding of electrodes Water cycle exclusively for aluminium cutting Safety FeaturesEnclosed work area with interlocked doors ensures higher operator safety Enclosed belt wheels with interlocked covers to ensure safe replacement of the belt Built-in fume extractor with coolant separating facility for fume-free work environment, without loss of the coolant Easy maintenanceSeparate automatic wash cycle for cleaning the work area automatically with a single-key operation Easily replaceable ceramic guides and carbon brushes allow easy maintenanceDielectric Pump unitSodium Silicate capacity : 285 Litres Water tank capacity : 285 Litres Standard accessoriesStrip butt welder Fume extractors Centralised lubrication system Automatic servo-controlled voltage stabiliser Manual Clamping set Optional accessoriesMotorised trolley / roller conveyor Pneumatic clamping system Types of controlFunctional control : Micro-controller based Servo control : PWM DC Servo Data input and outputSpecial-function sealed keyboard Hand-held remote Operating aidsAudiovisual alarm for fault indication Manual Up / Down switch Auto-positioning Gap control DRO for Z axis and optional Y axis

Ecoline Electric Discharge Machine

Get Price Quote

DISCHARGE MACHINES

Get Price Quote

electric discharge machine

Get Price Quote

We are offering electric discharge machine. Electronika and tool craft analog type machines can be serviced. Trouble shooting of electrode sparking, tool up & down servo motor control pcbs are carried out and spare pcbs also can be supplied.

E Rickshaw Backlight

120 Per Piece

electric discharge machine

Get Price Quote

We are most reliable suppliers, manufacturers, exporters of Electric Discharge Machine with various specifications.

electric discharge machine

Get Price Quote

1 Piece (MOQ)

electric discharge machine, 5030 ZNC EDM Machine, 4025 ZNC EDM Machine

electric discharge machines

Get Price Quote

electric discharge machines, electronic billing machine

electric discharge machine

Get Price Quote

hi performance EDM From Indian manufacturer, Traverses- 275, 200, 250 MM As XYZ Respectivally. AC Servo motor + drive From Mitsubishi, MRR (Copper to Steel) is 200mm3/ Min and Graphite to Steel is 300mm3/min, Best Surface Finish is 0.6u Ra, Electrode Wear

electric discharge machine

Get Price Quote

electric discharge machine, CNC Wire Cut, edm products

electric discharge machine

Get Price Quote

electric discharge machine, CNC Wire Cut, edm products

electrical discharge machines

Get Price Quote

electrical discharge machines, electrical accessories. electrical goods

electric discharge machines

Get Price Quote

electric discharge machines, Dies, Jigs, cnc wire cutting machines

electric discharge machine

Get Price Quote

electric discharge machine, CNC Wire Cut, edm products

Electrical Discharge Machine

Get Price Quote

Electrical Discharge Machine, axis gantry machining center

electric discharge machine

Get Price Quote

electric discharge machine, cnc wire, edm cut machines, Electronic Products